Nissan Maxima Service and Repair Manual: P0868 transmission fluid pressure

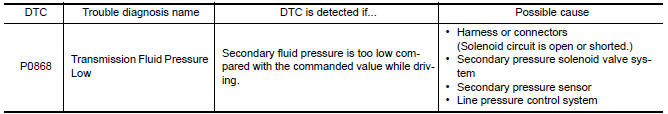

Description

The secondary pressure solenoid valve regulates the secondary pressure to suit the driving condition in response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

Select "Data Monitor" in "TRANSMISSION".

-

Check that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN : 1.0 - 2.0 V

If it is out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage (cool down the fluid)

4. Start engine and maintain the following conditions for at least 10 consecutive seconds.

VEHICLE SPEED (accelerate slowly) : 0 → 50 km/h (31 MPH)

ACC PEDAL OPEN : 0.5/8 - 1.0/8

RANGE : "D" position

Diagnosis Procedure

1.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-162, "Inspection and Judgment".

2.CHECK SECONDARY PRESSURE SOLENOID VALVE

-

Turn ignition switch OFF.

-

Disconnect CVT unit connector.

-

Check secondary pressure solenoid valve. Refer to TM-94, "Component Inspection (Secondary Pressure Solenoid Valve)".

3.CHECK LINE PRESSURE SOLENOID VALVE

Check line pressure solenoid valve. Refer to TM-94, "Component Inspection (Line Pressure Solenoid Valve)".

4.CHECK SECONDARY PRESSURE SENSOR SYSTEM

Check secondary pressure sensor system. Refer to TM-85, "DTC Logic".

5.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

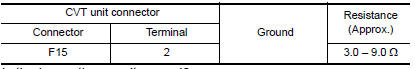

Component Inspection (Line Pressure Solenoid Valve)

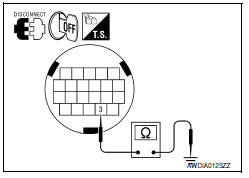

1.CHECK LINE PRESSURE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

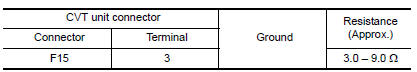

Component Inspection (Secondary Pressure Solenoid Valve)

1.CHECK SECONDARY PRESSURE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

P0845 transmission fluid pressure SEN/SW B

P0845 transmission fluid pressure SEN/SW B

Description

The primary pressure sensor detects primary pressure of CVT and sends a

signal to the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

Immediately after perfo ...

P1701 TCM

P1701 TCM

Description

When the power supply to the TCM is cut off, for example

because the battery is removed, and the self-diagnosis

memory function stops, a malfunction is detected.

NOTE:

Since "P1701 ...

Other materials:

The oil pressure warning lamp does not turn off

Description

The oil pressure warning lamp remains illuminated while

the engine is running (normal oil pressure).

Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-87,

"Wiring Diagram".

1.CHECK OIL PRESSURE WARNING LAMP

Perform IPDM E/R auto active test. Refer to PCS-11, ...

Clearing the programmed information

The following procedure clears the programmed

information from both buttons. Individual buttons

cannot be cleared. However, individual buttons

can be reprogrammed. For additional information,

refer to "Reprogramming a single

HomeLink button" in this section.

To clear all programming:

1. Press ...

Memory function does not operate

Component Function Check

Symptom

Memory function does not operate normally.

The setting is not maintained. (It returns to the initial

condition.)

1.CHECK OPERATION

Set temperature control switch to 32C (90F).

Press the OFF switch.

Turn the ignition switch OFF.

Turn the ignitio ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0057