Nissan Maxima Service and Repair Manual: P1701 TCM

Description

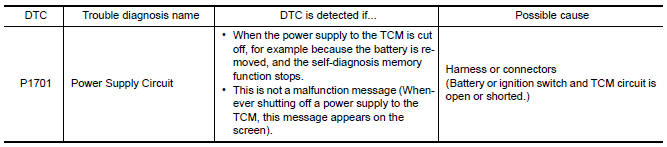

When the power supply to the TCM is cut off, for example because the battery is removed, and the self-diagnosis memory function stops, a malfunction is detected.

NOTE: Since "P1701" is indicated when replacing TCM, perform diagnosis after erasing "Self Diagnostic Results".

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

Wait for at least 2 consecutive seconds.

-

Perform "Self Diagnostic Results" in "TRANSMISSION".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-126, "Wiring Diagram".

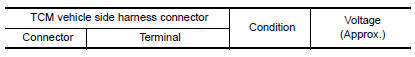

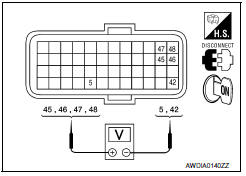

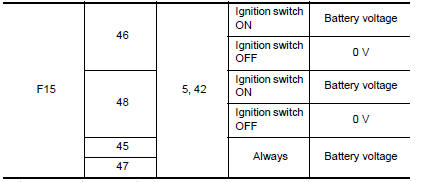

1.CHECK TCM POWER SOURCE

-

Turn ignition switch OFF.

-

Disconnect TCM connector.

-

Check voltage between TCM vehicle side harness connector terminals.

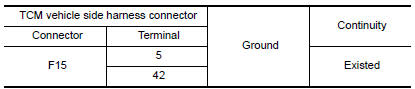

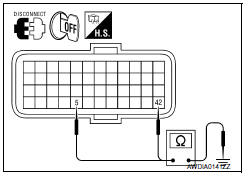

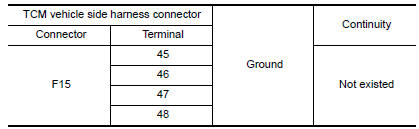

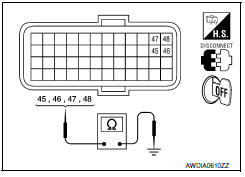

2.CHECK TCM GROUND CIRCUIT

-

Turn ignition switch OFF.

-

Check continuity between TCM vehicle side harness connector terminals and ground.

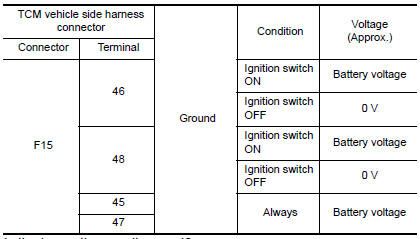

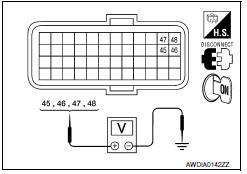

3.CHECK TCM POWER CIRCUIT

Check voltage between TCM vehicle side harness connector terminals and ground.

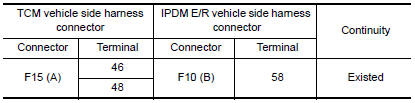

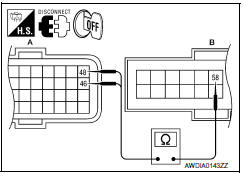

4.CHECK HARNESS BETWEEN TCM AND IPDM E/R AND BETWEEN TCM AND BATTERY (PART 1)

-

Turn ignition switch OFF.

-

Disconnect IPDM E/R connector.

-

Check continuity between TCM vehicle side harness connector terminals and IPDM E/R vehicle side harness connector terminal.

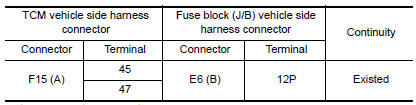

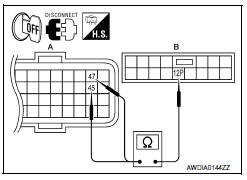

4. Disconnect fuse block (J/B) connector.

5. Check continuity between TCM vehicle side harness connector terminals and fuse block (J/B) vehicle side harness connector terminal.

5.CHECK HARNESS BETWEEN TCM AND IPDM E/R AND BETWEEN TCM AND BATTERY (PART 2)

Check continuity between TCM vehicle side harness connector terminals and ground.

6.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

P0868 transmission fluid pressure

P0868 transmission fluid pressure

Description

The secondary pressure solenoid valve regulates the

secondary pressure to suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC ...

P1705 TP sensor

P1705 TP sensor

Description

The electric throttle control actuator consists of

throttle control motor, accelerator pedal position sensor, throttle

position sensor, etc. The actuator sends a signal to the ECM, an ...

Other materials:

Power supply and ground circuit

POWER SUPPLY AND GROUND CIRCUIT AUDIO UNIT

AUDIO UNIT : Diagnosis Procedure

1.CHECK FUSES

Check that the following fuses are not blown.

2.POWER SUPPLY CIRCUIT CHECK

Disconnect audio unit connector M133.

Check voltage between the audio unit connector M133 and ground.

3.GROUND C ...

U1300 AV comm circuit

Description

U1300 is indicated when a communication signal malfunction occurs. U1300 is

indicated along with DTCs that

identify components connected to the AV control unit through communication

lines. Determine the possible

malfunction cause from the table below.

SELF-DIAGNOSIS RESULTS DIS ...

U1000 CAN comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0062