Nissan Maxima Service and Repair Manual: Removal and installation

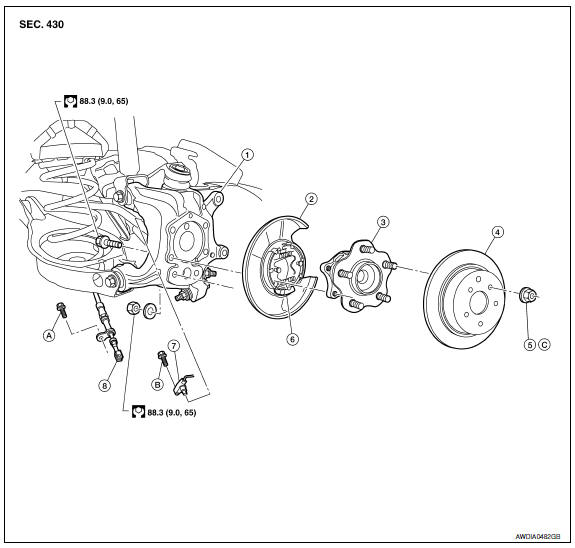

WHEEL HUB

Removal and Installation

- Knuckle

- Baffle plate

- Wheel hub assembly

- Brake rotor

- Wheel nut

- Anchor block

- Wheel sensor

- Parking brake cable

- Refer to PB-6, "Exploded View".

- Refer to BRC-103, "Removal and Installation - Rear Wheel Sensor".

- Refer to WT-65, "Road Wheel".

REMOVAL

CAUTION: Wheel hub assembly does not require maintenance. If any of the following symptoms are noted, replace the wheel hub assembly.

- A growling noise is emitted from the wheel hub assembly while driving.

- The wheel hub assembly drags or turns roughly.

- Remove the rear wheel and tire using power tool. Refer to WT-60, "Adjustment".

- Remove the brake caliper assembly and brake rotor using power tool. Refer to BR-36, "Removal and Installation of Brake Caliper and Rotor".

- The brake hose does not need to be disconnected from the brake caliper.

CAUTION:

- Suspend the brake caliper assembly using wire, do not stretch the brake hose.

- Do not depress the brake pedal, or the caliper piston will pop out.

- Do not twist the brake hose.

- Remove the rear wheel sensor, then move it away from the wheel hub

assembly. Refer to BRC-103, "Removal and Installation - Rear Wheel

Sensor".

CAUTION: Failure to remove the wheel sensor may result in damage to the sensor wires and the sensor being inoperative. - Remove the wheel hub assembly from knuckle.

INSPECTION AFTER REMOVAL

Check for any deformity, cracks, or damage on the wheel hub assembly, replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

- Check that the wheel bearings operate smoothly.

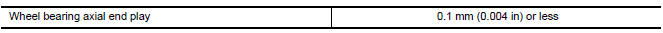

- Check that the wheel hub bearing axial end play is within specification.

Axial end play : Refer to RAX-8, "Wheel Bearing (Rear)".

- Tighten wheel nut to specification.

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Bearing (Rear)

Periodic maintenance

Periodic maintenance

WHEEL HUB

On-vehicle Service

Check axle and suspension parts for excessive play, wear or damage.

Shake each rear wheel to check for excessive play.

Inspection

Rear Wheel Bearing

...

Suspension

Suspension

...

Other materials:

Engine coolant temperature gauge

The gauge indicates the engine coolant temperature.

The engine coolant temperature is within the

normal range 1 when the gauge needle points

within the zone shown in the illustration.

The engine coolant temperature varies with the

outside air temperature and driving conditions.

CAUTION ...

System temporarily unavailable

Condition A

When the radar sensor picks up interference

from another radar source, making it impossible

to detect a vehicle ahead, the PFCW system is

automatically turned off.

The FEB system warning light (orange) will illuminate.

Action to take

When the above conditions no longer exist, th ...

Inspection and adjustment

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Description

Initial setting is necessary when battery terminal is removed.

CAUTION:

The following specified operations are not performed under the

non-initialized condition. ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0056