Nissan Maxima Service and Repair Manual: Vacuum lines

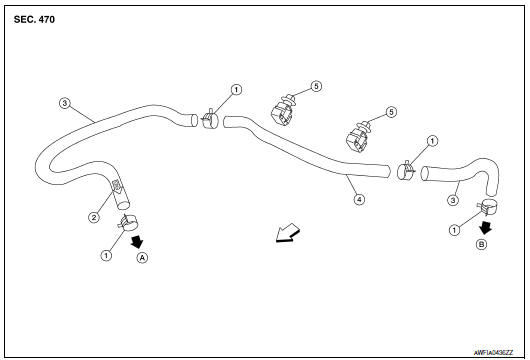

Exploded View

- Clamp

- Installation arrow

- Vacuum hose

- Vacuum pipe

- Clip

- To intake manifold

- To brake booster

Front

Front

Removal and Installation

REMOVAL

- Disconnect the vacuum hose from the brake booster.

- Disconnect the vacuum hose from the intake manifold.

- Release the clips and remove the vacuum pipe with the vacuum hoses attached.

- Remove the vacuum hoses from the vacuum pipe.

INSPECTION AFTER REMOVAL

Visual Inspection

Check for correct installation, damage and deterioration of the vacuum hoses and pipe.

Valve Air-tightness Check

- Connect a suitable tool (hand vacuum pump) at each end of the vacuum hose to inspect the check valve operation.

- Replace the vacuum hose component or check valve if out of specification

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Because the vacuum hose contains a check valve, the vacuum hose must be installed in the correct position for proper operation. Refer to the stamp on the end of the vacuum hose to confirm correct installation. The brake booster will not operate normally if the vacuum hose with the check valve is installed in the wrong direction.

- Insert the vacuum pipe into the vacuum hose at least 24 mm (0.94 in) as shown.

- Do not use lubricating oil during installation.

Brake booster

Brake booster

Exploded View

Master cylinder assembly

Brake booster

Brake pedal

Lock nut

Gasket

Removal and installation

NOTE:

When removing components such as hoses, tubes/lines, etc., cap ...

Front disc brake

Front disc brake

Exploded View of Brake Pads

Inner shim cover

Inner shim

Inner pad

Outer pad

Outer shim

Outer shim cover

Anti-rattle clips

Pad retainers

Molykote AS-880N grease

Mo ...

Other materials:

The ambient temperature display is incorrect

Description

The displayed ambient air temperature is higher

than the actual temperature.

The displayed ambient air temperature is lower

than the actual temperature.

Diagnosis Procedure

1.COMBINATION METER INPUT SIGNAL

Select "METER/M&A" on CON ...

Evaporative emission system

System Diagram

System Description

*1: ECM determines the start signal status by the signals of engine speed and

battery voltage.

*2: This signal is sent to the ECM via the CAN communication line.

SYSTEM DESCRIPTION

The evaporative emission system is used to reduce hydrocarbons emitte ...

Remote Engine Start

The button will be on the NISSAN

Intelligent

Key if the vehicle has remote engine start.

This feature allows the engine to start from outside

the vehicle.

The following features may be affected when the

remote start feature is used:

Vehicles with an automatic climate control

sys ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0072