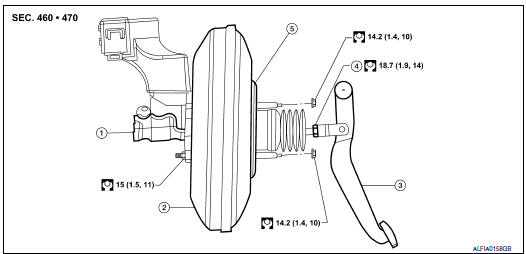

Nissan Maxima Service and Repair Manual: Brake booster

Exploded View

- Master cylinder assembly

- Brake booster

- Brake pedal

- Lock nut

- Gasket

Removal and installation

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Release the fuel pressure. Refer to EC-592, "Inspection".

- Disconnect the battery negative terminal. Refer to PG-67, "Exploded View".

- Remove the engine room cover. Refer to EM-23, "Removal and Installation".

- Remove the air cleaner and air duct. Refer to EM-24, "Removal and Installation".

- Remove cowl top, cowl top extension LH and the lower cowl top extension brace. Refer to EXT-20, "Exploded View".

- Disconnect fuel line from engine, clip and main line and reposition out of the way.

- Remove master cylinder. Refer to BR-24, "Removal and Installation".

- Disconnect vacuum hose from brake booster.

- Remove instrument lower panel LH. Refer to IP-10, "Exploded View".

- Disconnect the harness connector from the accelerator pedal.

- Remove snap pin and clevis pin from inside vehicle.

- Disconnect the steering column upper joint and reposition it out of the way.

- Disconnect the harness connectors from the ASCD cancel switch and stop lamp switch.

- Remove nuts on brake booster and brake pedal assembly, then remove brake pedal. Refer to BR-18, "Exploded View".

- Remove brake booster from dash panel on engine room side.

CAUTION: Be careful not to deform or bend brake tube while removing brake booster. - Remove the brake booster gasket.

INSTALLATION

CAUTION:

- Be careful not to deform or bend brake tube while installing brake booster.

- Replace clevis pin if it is damaged.

- Do not damage brake booster stud bolt threads. If brake booster is tilted during installation, the dash panel may damage the threads.

- Loosen lock nut to adjust input rod length (B) to the specified value as shown.

Input rod length (B) : Refer to BR-46, "Brake Booster".

- After adjusting input rod length (B), temporarily tighten the lock

nut to install the booster assembly. At this time, make sure that a

gasket between booster assembly and dash panel is installed.

CAUTION: Always install gasket between brake booster and dash panel. - Install and connect brake pedal with clevis of input rod.

- Install brake pedal bracket nuts and tighten them to the specified torque. Refer to BR-18, "Exploded View".

- Connect the ASCD cancel switch and stop lamp switch harness connectors.

- Connect the steering column upper joint.

- Connect the accelerator pedal harness connector.

- Install instrument lower panel LH. Refer to IP-10, "Exploded View".

- Install vacuum hose into brake booster.

- Install master cylinder. Refer to BR-24, "Removal and Installation".

- Position fuel line and connect to engine, clip and main line.

- Install the air cleaner and air duct. Refer to EM-24, "Removal and Installation".

- Install the engine room cover. Refer to EM-23, "Removal and Installation".

- Install the cowl top, cowl top extension LH and the lower cowl top extension brace. Refer to EXT-20, "Exploded View".

- Connect the battery negative terminal. Refer to PG-67, "Exploded View".

- Adjust the brake pedal height, if necessary. Refer to PG-67, "Exploded View".

- Tighten lock nut of input rod to the specified torque. Refer to BR-26, "Exploded View".

- Refill new brake fluid and bleed air. Refer to BR-16, "Bleeding Brake System".

Brake master cylinder

Brake master cylinder

Exploded View

Reservoir cap

Oil strainer (blue)

Master cylinder assembly

Brake fluid level switch harness connector

O-ring

PBC (Poly Butyl Cuprysil) grease or

silicone-ba ...

Vacuum lines

Vacuum lines

Exploded View

Clamp

Installation arrow

Vacuum hose

Vacuum pipe

Clip

To intake manifold

To brake booster

Front

Removal and Installation

REMOVAL

Disconnect the vacuum ...

Other materials:

Opener operation

To open the trunk lid, push the opener switch.

To close the trunk lid, lower and push the trunk lid

down securely.

NOTE:

You can open the trunk lid with the Intelligent

Key. For additional information, refer

to "NISSAN Intelligent Key" in this section.

Cancel switch

When the cancel ...

ECU diagnosis information

BCM (BODY CONTROL MODULE)

Reference Value

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS tran ...

Three-point type seat belt with retractor

WARNING

Every person who drives or rides in this

vehicle should use a seat belt at all

times. Children should be in the rear

seats and in an appropriate restraint.

Do not ride in a moving vehicle when

the seatback is reclined. This can be

dangerous. The shoulder belt will not

be ag ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0067