Nissan Maxima Service and Repair Manual: Brake master cylinder

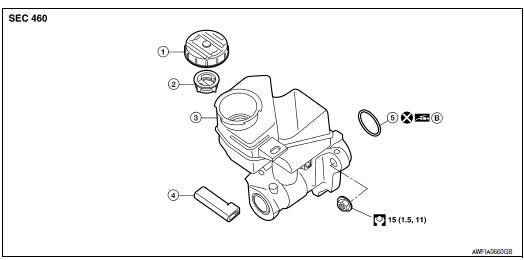

Exploded View

- Reservoir cap

- Oil strainer (blue)

- Master cylinder assembly

- Brake fluid level switch harness connector

- O-ring

- PBC (Poly Butyl Cuprysil) grease or silicone-based grease

Removal and Installation

CAUTION:

- Do not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed on painted areas, wash it away with water immediately.

- Refill with new brake fluid.

- Do not reuse drained brake fluid.

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove the engine room cover. Refer to EM-23, "Removal and Installation".

- Remove the air cleaner and air duct. Refer to EM-24, "Removal and Installation".

- Disconnect the harness connector from the brake fluid level switch.

- Disconnect master cylinder brake tubes, using a suitable tool.

- Remove master cylinder nuts.

- Remove master cylinder assembly and O-ring.

CAUTION: Do not reuse O-ring.

INSTALLATION

Installation is in the reverse order of removal.

- Apply silicone grease to brake booster at position (A) as shown, be

sure the O-ring is in proper position when installing master cylinder

to brake booster.

CAUTION: Do not reuse O-ring. - Tighten brake tube flare nut to the specified torque using a suitable tool. Refer to BR-20, "Hydraulic Circuit".

- Refill the brake hydraulic system with new brake fluid and bleed air. Refer to BR-16, "Bleeding Brake System".

- If necessary, adjust the brake booster input rod length. Refer to BR-46, "Brake Booster".

Brake tube and hose

Brake tube and hose

Hydraulic Circuit

Actuator

Master cylinder

Brake booster

Connector A. Union bolt

18.2 N*m (1.9 kg-m, 13 ft-lb)

B. Flare nut M12

22.1 N*m (2.3 kg-m, 16 ft-lb)

C. Flare nut M ...

Brake booster

Brake booster

Exploded View

Master cylinder assembly

Brake booster

Brake pedal

Lock nut

Gasket

Removal and installation

NOTE:

When removing components such as hoses, tubes/lines, etc., cap ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis Flow Chart

Trouble Diagnosis Procedure

INTERVIEW WITH CUSTOMER

Interview with the customer is important to detect the root cause of CAN

communication system errors and to

understand vehicle condition and symptoms for proper trouble diagnosis ...

Front drive shaft

Removal and Installation (LH)

Drive shaft

Cotter pin

REMOVAL

Remove wheel and tire using power tool. Refer to WT-60, "Adjustment".

Remove wheel sensor from steering knuckle. Refer to BRC-102,

"Removal and Installation - Front Wheel Sensor".CAUTION: Do not

pull o ...

Hands-free phone system

System Diagram

System Description

Refer to the Owner's Manual for Bluetooth telephone system operating

instructions. NOTE: Cellular

telephones must have their wireless connection set up (paired) before using the

Bluetooth telephone system. Bluetooth telephone system allows users

who have ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0066