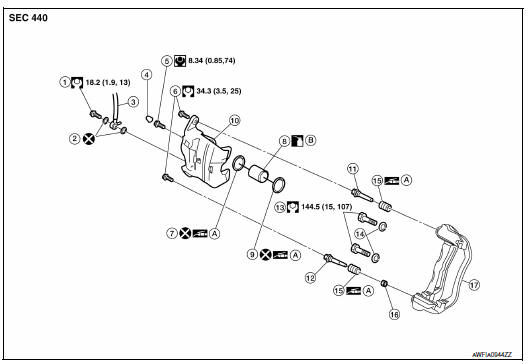

Nissan Maxima Service and Repair Manual: Front disc brake

Disassembly and Assembly

- Union bolt

- Copper sealing washer

- Brake hose

- Cap

- Bleed valve

- Sliding pin bolt

- Piston seal

- Piston

- Piston boot

- Cylinder body

- Upper sliding pin

- Lower sliding pin bolt

- Torque member bolt

- Washer

- Sliding pin boot

- Bushing

- Torque member

- Rubber grease

- Brake fluid

NOTE: Do not remove the torque member, pads, shims, shim covers, and anti-rattle clips when disassembling and assembling the cylinder body.

DISASSEMBLY

- Remove the sliding pin bolts, and then remove the cylinder body

from the torque member.

CAUTION: Do not drop pads, shims, shim cover and anti-rattle clips from torque member. - Remove the sliding pins, bushing and sliding pin boots from the torque member.

- Remove the cap and the bleed valve from the cylinder body.

- Place a wooden block in the cylinder body and blow air through

the union bolt hole to push out the piston and piston boot as

shown. Discard the piston boot.

WARNING:

Do not get fingers caught between the piston and cylinder

body.

CAUTION: Do not reuse the piston boot.

- Remove the piston seal from the cylinder body using a suitable tool as shown. Discard the piston seal.

CAUTION:

- Be careful not to damage the inner cylinder wall.

- Do not reuse the piston seal.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner cylinder wall for corrosion, wear, and damage. If a defect is detected, replace the cylinder body.

CAUTION: Clean the cylinder body using new brake fluid. Do not use mineral oils such as gasoline or kerosene.

Torque Member

Check the torque member for wear, cracks, and damage. If a defect is detected, replace the torque member.

Piston

Check the piston surface for corrosion, wear, and damage. If a defect is detected, replace the piston.

CAUTION: The piston sliding surface is plated. Do not polish the piston with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

Check the sliding pin, sliding pin bolt, and sliding pin boot for wear, damage, and cracks. If a defect is detected, replace the components as necessary.

ASSEMBLY

- Apply rubber grease to the new piston seal, and install it in the cylinder body.

CAUTION: Do not reuse piston seal.

- Apply rubber grease to new piston boot and apply brake fluid to

the piston. Cover the piston end with the piston boot, and then

install the cylinder side lip on the piston boot securely into a

groove on the cylinder body.

CAUTION: Do not reuse piston boot.

- Push the piston into the cylinder body by hand and push the piston

boot piston-side lip into the piston groove.

CAUTION: Press the piston evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.

- Install the bleed valve and cap to the cylinder body.

- Install the sliding pins, bushing and sliding pin boots on the torque member.

- Install the cylinder body to the torque member, and then tighten the sliding pin bolts to the specified torque.

Rear disc brake

Rear disc brake

Disassembly and Assembly

Union bolt

Brake hose

Copper sealing washer

Cap

Bleed valve

Lower sliding pin bolt

Upper sliding pin bolt

Bushing

Cylinder body

Piston seal

P ...

Other materials:

Brake warning lamp

Description

NOTE:

1: Brake warning lamp will turn on in case of parking brake operation

(when switch is ON) or of brake fluid level switch operation

(when brake fluid is insufficient).

2: After starting engine, brake warning lamp is turned off.

Component Function Check

1.B ...

Power window main switch

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH

Fail Safe

FAIL-SAFE CONTROL

Switches to fail-safe control when malfunction is detected in encoder signal

that detects up/down speed and

direction of door glass. Switches to fail-safe c ...

Disk eject signal circuit

Description

The eject signal is output to AV control unit when the eject switch of A/C

and AV switch assembly is pressed.

Diagnosis Procedure

1.CHECK CONTINUITY DISK EJECT SIGNAL CIRCUIT

Turn ignition switch OFF.

Disconnect A/C and AV switch assembly connector M98 and AV

control un ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0231