Nissan Maxima Service and Repair Manual: Steering gear and linkage

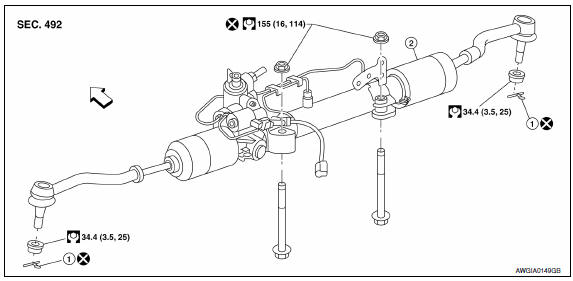

Exploded View

- Cotter pin

- Steering gear assembly

Front

Front

Removal and Installation

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove front wheel and tire using power tool. Refer to WT-60, "Adjustment".

- Drain power steering fluid. Refer to ST-12, "Draining".

- Disconnect front stabilizer connecting rods from front stabilizer and reposition front stabilizer. Refer to FSU-11, "Removal and Installation".

- Remove steering outer socket cotter pins (1), and then loosen the nuts.

- Remove steering outer sockets (2) from steering knuckles (3) so as not to damage ball joint boots (4) using Tool.

CAUTION: Temporarily tighten the nut to prevent damage to threads and to prevent the Tool from suddenly coming off.

Tool number : HT72520000 (J-25730-A)

- Remove side bolt (A) of lower shaft assembly (1) and disconnect lower

shaft assembly.

- Steering gear assembly (2) - Remove front exhaust tube. Refer to EX-5, "Removal and Installation".

- Disconnect the harness connector from the SSPS valve. Refer to ST-33, "Exploded View".

- Disconnect high and low pressure piping from steering gear assembly. Refer to ST-29, "Exploded View"

- Remove steering hydraulic piping bracket from front suspension member.

- Remove bolts and nuts of steering gear assembly, and then remove steering gear assembly from vehicle.

INSPECTION AFTER REMOVAL

Check for fluid leaks or damage to steering gear assembly. If any exist, replace steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse cotter pins.

- Do not reuse steering gear assembly nuts.

- When installing lower shaft assembly to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE: To get the neutral position of rack, turn gear sub-assembly and measure the distance of inner socket, and then measure the intermediate position of the distance.

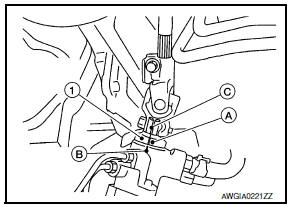

- Align rear cover cap projection (A) with the marking position (B) of gear housing assembly.

- Install slit part of lower shaft assembly (C) aligning with the projection (A) of rear cover cap (1). Make sure that the slit part of lower shaft assembly (C) is aligned with both the projection (A) of rear cover cap (1) and the marking position (B) of gear housing assembly.

- Connect the high and low pressure piping to the steering gear.

Tighten to specification. Refer to ST-30, "Removal and Installation".

- After installation, bleed air from the steering hydraulic system.

Refer to ST-12, "Inspection".

- Check wheel alignment.

INSPECTION AFTER INSTALLATION

Make sure that steering wheel operates smoothly by turning several times from full left stop to full right stop.

Steering column

Steering column

Without Electric Motor

-4. Steering column assembly nut tightening order

Steering wheel

Combination switch and spiral cable

Steering column assembly

Hole cover seal

Herbie c ...

Power steering oil pump

Power steering oil pump

Exploded View

Rear bracket

Power steering oil pump assembly

Front bracket

Removal and Installation

NOTE: When removing components such as

hoses, tubes/lines, etc., cap or plug open ...

Other materials:

Sliding sensor

Description

The sliding sensor is installed to the seat frame.

The pulse signal is input to the driver seat control unit when sliding

is performed.

The driver seat control unit counts the pulse and calculates the sliding

amount of the seat.

Component Function Check

1. CHECK FUNCTIO ...

Removal and installation

GENERATOR

Exploded View

-3 Tightening order

Generator

B terminal nut

Generator bracket

Front

Removal and Installation

REMOVAL

Remove hoodledge covers (LH/RH).

Remove cooling fan assembly. Refer to CO-16, "Removal and

Installation".

Remove the A/C compre ...

Electronic controlled engine mount

System Diagram

System Description

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM via the CAN communication line.

SYSTEM DESCRIPTION

The ECM controls the engine mount operation corresponding to the engine

speed. The control system has a

2-step control [Soft/Hard]

EL ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0088