Nissan Maxima Service and Repair Manual: Power steering oil pump

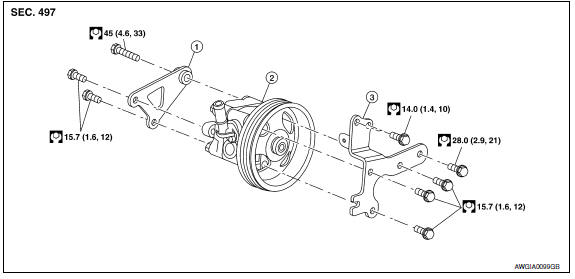

Exploded View

- Rear bracket

- Power steering oil pump assembly

- Front bracket

Removal and Installation

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove front wheel and tire (RH) using power tool. Refer to WT-60, "Adjustment".

- Remove front fender protector side cover. Refer to EXT-23, "Exploded View".

- Remove hood ledge cover (RH).

- Drain power steering fluid. Refer to ST-12, "Draining".

- Disconnect the power steering pressure sensor harness connector at the high pressure pipe. Refer to ST- 29, "Exploded View".

- Disconnect high pressure piping and suction hose from power steering oil pump. Refer to ST-29, "Exploded View".

- Loosen drive belt. Refer to EM-14, "Removal and Installation".

- Remove drive belt from power steering oil pump pulley.

- Remove power steering oil pump bolts, and then remove power steering oil pump.

INSTALLATION

Installation is in the reverse order of removal.

- When installing power steering oil pump, install all bolts by hand initially, then tighten bolts to specification.

- Perform the following procedures after installing.

- Check belt tension. Refer to EM-14, "Checking Drive Belts".

- Bleed air from power steering system.

Steering gear and linkage

Steering gear and linkage

Exploded View

Cotter pin

Steering gear assembly Front

Removal and Installation

NOTE: When removing components such as

hoses, tubes/lines, etc., cap or plug openings to prevent fluid ...

Hydraulic line

Hydraulic line

Exploded View

High pressure hose

Suction hose

Reservoir tank bracket

Reservoir tank

Oil pump assembly

Steering gear assembly

Low pressure piping

Eye bolt

High pressure pipin ...

Other materials:

Air conditioner system refrigerant and oil recommendations

The air conditioner system in your NISSAN

vehicle must be charged with the refrigerant

HFC-134a (R-134a) and Genuine

NISSAN A/C System Oil Type ND-OIL8 or

the exact equivalents.

CAUTION

The use of any other refrigerant or oil may

cause severe damage to the air conditioning

system and may req ...

Blower motor control system

System Diagram

System Description

Fan speed is automatically controlled by the temperature setting, ambient

temperature, in-vehicle temperature,

intake temperature, amount of sunload and air mix door position.

By pressing the AUTO switch, the blower motor starts to gradually increase

a ...

How to switch the display

With the ignition switch in the ON position, press

the CAMERA button or move the shift lever to the

R (Reverse) position to operate the Around

View Monitor.

The Around View Monitor displays different

split screen views depending on the position of

the shift lever. Press the CAMERA button to

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0078