Nissan Maxima Service and Repair Manual: Exit assist function

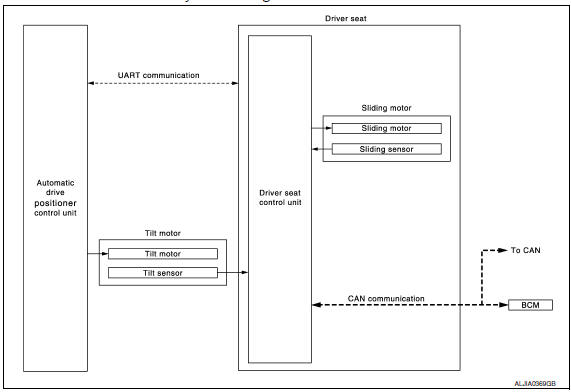

EXIT ASSIST FUNCTION : System Diagram

EXIT ASSIST FUNCTION : System Description

OUTLINE

When exiting, if the conditions are satisfied, the seat is moved backward from normal sitting position and the steering column is moved up.

The seat slide amount at entry/exit operation can be changed.

NOTE:

- This function is set to ON before delivery (initial setting).

- - Further information for the system setting procedure. Refer to Owner's Manual.

OPERATION PROCEDURE

- Open the front door LH with ignition switch in OFF position.

- Front seat LH and steering column will move to the exiting position.

OPERATION CONDITION

Satisfy all of the following items. The exit assist function is not performed if these items are not satisfied.

| Item | Request status |

| Ignition switch | OFF |

| System setting [Entry/exit assist function] | ON |

| Initialization | Done |

|

Switch inputs

|

OFF (Not operated) |

| CVT selector lever | P position |

DETAIL FLOW

| Order | Input | Output | Control unit condition |

| 1 | Front door switch LH | - | Driver seat control unit receives front door switch LH signal (open) from BCM via CAN communication |

| 2 | - | Motors (seat sliding, tilt) | Driver seat control unit operates the seat sliding motor, which

recognizes that the driver side door is opened with ignition switch

OFF.

Driver seat control unit then requests the operations of tilt motor to auto drive positioner control unit via UART communication. The automatic drive positioner control unit operates each motor for a constant amount. |

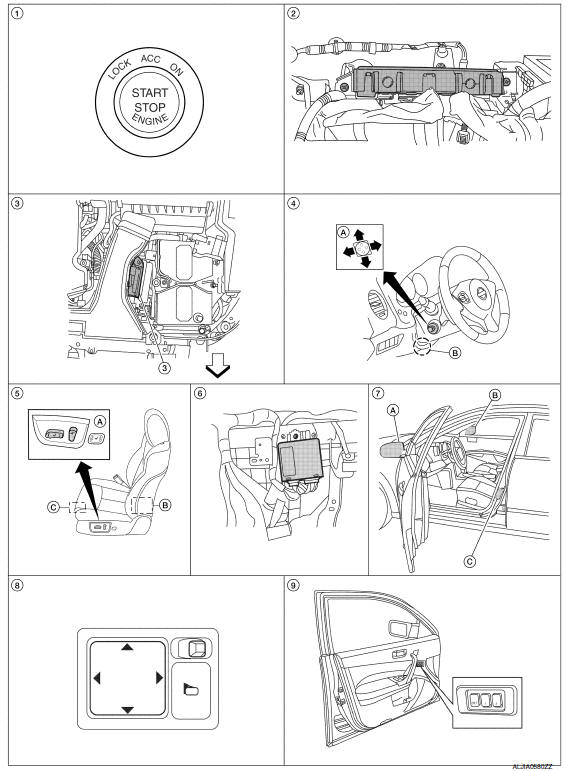

EXIT ASSIST FUNCTION : Component Parts Loca

- Push-button ignition switch M38

- BCM M16, M17, M18, M19 (view with instrument panel removed)

- TCM F15

- A. ADP steering switch M39

B. Tilt motor M71, telescopic motor M73 - A. Power seat switch LH B213

B. Reclining motor B222

C. Driver seat control unit B203, B211 - Automatic drive positioner control unit M63, M67 (view with instrument panel removed)

- A. Door mirror LH D4

B. Door mirror RH D107

C. Front door switch LH B8 - Door mirror remote control switch M108

- Seat memory switch D13

: Front

: Front

EXIT ASSIST FUNCTION : Component Description

CONTROL UNITS

| Item | Function |

| Driver seat control unit |

|

| Automatic drive positioner control unit | Operates the tilt motor with the request from the driver seat control unit |

| BCM |

Recognizes the following status and transmits it to the driver seat control unit via CAN communication.

|

INPUT PARTS

Switches

| Item | Function |

| Front door switch LH | Detect front door LH open/close statu |

Sensors

| Item | Function |

| Tilt sensor | Detect the up/down position of steering column. |

| Sliding sensor | Detect the front/rear position of seat. |

OUTPUT PARTS

| Item | Function |

| Tilt motor | Move the steering column up/down. |

| Sliding motor | Slide the seat forward/backward |

Memory function

Memory function

MEMORY FUNCTION : System

MEMORY FUNCTION : System Description

OUTLINE

The driver seat control unit can store the optimum driving positions (seat,

steering column and door mirror position) for ...

Entry assist function

Entry assist function

ENTRY ASSIST FUNCTION : System Diagram

ENTRY ASSIST FUNCTION : System Description

OUTLINE

The seat is in the exiting position when either following condition is

satisfied, the seat returns fr ...

Other materials:

Programming trouble-diagnosis

If the HomeLink does not quickly learn the

hand-held transmitter information:

replace the hand-held transmitter batteries

with new batteries.

position the hand-held transmitter with its

battery area facing away from the

HomeLink surface.

press and hold both the HomeLink and

hand-hel ...

Replacement operations

Description

This section is prepared for technicians who have attained a high level of

skill and experience in repairing collision-

damaged vehicles and also use modern service tools and equipment. Persons

unfamiliar with body

repair techniques should not attempt to repair collision-damaged ...

B1023 passenger air bag off indicator

Description

DTC B1023 FRONT PASSENGER AIR BAG OFF INDICATOR

The front passenger air bag off indicator is wired to the air bag diagnosis

sensor unit. The air bag diagnosissensor unit monitors the front passenger

air bag off indicator and circuit for failures.

PART LOCATION

DTC Logic

DTC DETE ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.009