Nissan Maxima Service and Repair Manual: B2555 stop lamp

Description

BCM detects the stop lamp status and confirms the stop lamp switch ON/OFF status. BCM confirms the engine start condition according to the stop lamp switch ON/OFF status.

DTC Logic

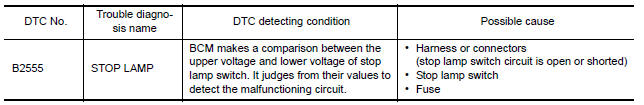

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

-

Depress the brake pedal and wait for at least 1 second.

-

Check "Self Diagnostic Result" with CONSULT.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-147, "Wiring Diagram" or SEC-128, "Wiring Diagram".

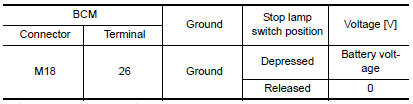

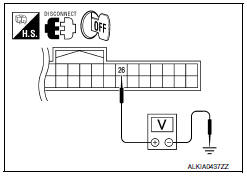

1.CHECK STOP LAMP SWITCH INPUT SIGNAL

-

Turn ignition switch OFF.

-

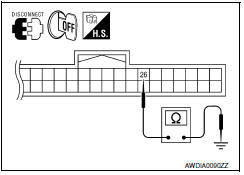

Disconnect BCM harness connector.

-

Check voltage between BCM harness connector M18 terminal 26 and ground.

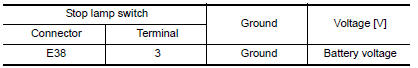

2.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

-

Disconnect stop lamp switch harness connector.

-

Check voltage between stop lamp harness connector E38 terminal 3 and ground.

3.CHECK STOP LAMP SWITCH CIRCUIT

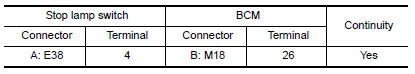

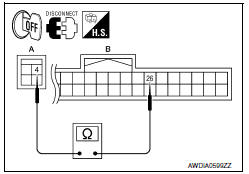

1. Check continuity between stop lamp switch harness connector E38 (A) terminal 4 and BCM harness connector M18 (B) terminal 26.

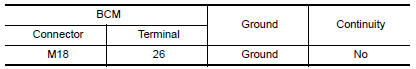

2. Check continuity between BCM harness connector M18 terminal 26 and ground.

4.CHECK STOP LAMP SWITCH

Refer to SEC-44, "Component Inspection".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

Inspection End.

Component Inspection

1.CHECK STOP LAMP SWITCH

-

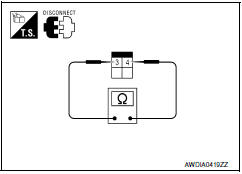

Turn ignition switch OFF.

-

Disconnect stop lamp switch harness connector.

-

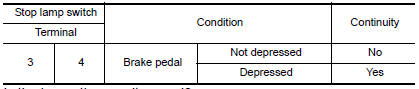

Check continuity between stop lamp switch terminals under the following conditions.

B2193 chain of ECM-IMMU

B2193 chain of ECM-IMMU

Description

BCM performs the ID verification with ECM that allows the

engine to start. Start the engine if the ID is OK.

ECM prevents the engine from starting if the ID is not registered. BCM st ...

B2556 push-button ignition switch

B2556 push-button ignition switch

Description

The switch that changes the power supply position. BCM

maintains the power supply position status. BCM

changes the power supply position with the operation of the push-button ignition ...

Other materials:

BCM (body control module)

Reference Value

NOTE:

The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS

transmitter IDs

Display tire pressure reported by

the TPMS transmitter

...

P0826 up and down shift SW

Description

Manual mode switch transmits signals (manual mode, not manual mode, shift up

and shift down) to combination

meter.

Paddle shifter transmits signals (shift up and shift down) to combination

meter. (With paddle shifter)

Combination meter transmits signals (manual mode, not manual ...

Sunroof does not operate properly

Diagnosis Procedure

1.CHECK SUNROOF MECHANISM

Check the following.

Operation malfunction caused by sunroof mechanism deformation,

pinched harness or other foreign materials

Operation malfunction and interference with other parts by poor

installation

2.CHECK SUNROOF MOTOR ASSEMBLY PO ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0064