Nissan Maxima Service and Repair Manual: B2601 shift position

Description

BCM confirms the shift position with the following 2 signals.

-

CVT selector lever

-

P position signal from IPDM E/R (CAN)

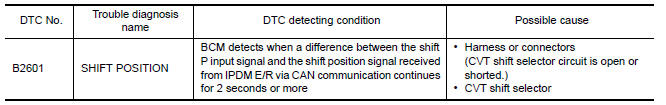

DTC Logic

DTC DETECTION LOGIC

NOTE:

-

If DTC B2601 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to SEC-29, "DTC Logic".

-

If DTC B2601 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to SEC-30, "DTC Logic".

-

If DTC B2601 is displayed with DTC B2605, first perform the trouble diagnosis for DTC B2605. Refer to SEC-61, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

-

Turn ignition switch ON under the following conditions, and wait for at least 2 seconds.

-

CVT selector lever is in the P position.

-

Do not depress the brake pedal.

-

-

Check "Self diagnostic result" with CONSULT.

-

Turn ignition switch ON under the following conditions, and wait for at least 2 seconds.

-

CVT selector lever is in other than P position.

-

Do not depress the brake pedal.

-

-

Check "Self diagnostic result" with CONSULT.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-147, "Wiring Diagram" or SEC-128, "Wiring Diagram".

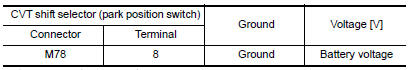

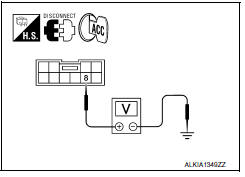

1.CHECK CVT SHIFT SELECTOR POWER SUPPLY

-

Turn ignition switch to ACC.

-

Disconnect CVT shift selector harness connector.

-

Check voltage between CVT shift selector harness connector M78 terminal 8 and ground.

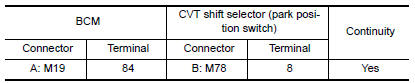

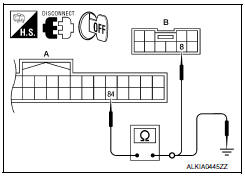

2.CHECK CVT SHIFT SELECTOR POWER SUPPLY CIRCUIT

-

Disconnect BCM harness connector.

-

Check continuity between BCM harness connector M19 (A) terminal 84 and CVT shift selector harness connector M78 (B) terminal 8.

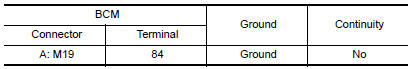

3. Check continuity between BCM harness connector M19 (A) terminal 84 and ground.

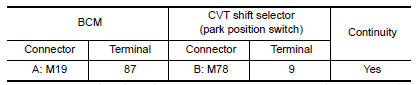

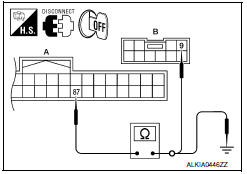

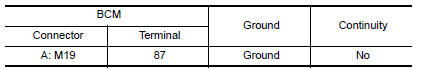

3.CHECK CVT SHIFT SELECTOR CIRCUIT (BCM)

-

Disconnect BCM harness connector and IPDM E/R harness connector.

-

Check continuity between BCM harness connector M19 (A) terminal 87 and CVT shift selector harness connector M78 (B) terminal 9.

3. Check continuity between BCM harness connector M19 (A) terminal 87 and ground.

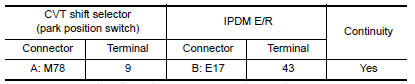

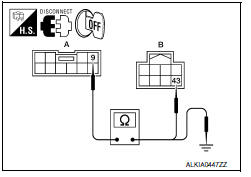

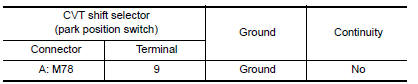

4.CHECK CVT SHIFT SELECTOR CIRCUIT (IPDM E/R)

-

Disconnect IPDM E/R harness connector.

-

Check continuity between CVT shift selector harness connector M78 (A) terminal 9 and IPDM E/R harness connector E17 (B) terminal 43.

3. Check continuity between CVT shift selector harness connector M78 (A) terminal 9 and ground.

5.CHECK CVT SHIFT SELECTOR

Refer to SEC-52, "Component Inspection".

6.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

Inspection End.

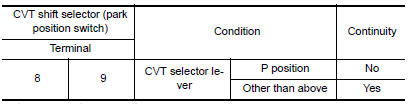

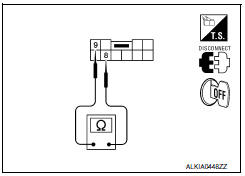

Component Inspection

1.CHECK CVT SHIFT SELECTOR

-

Turn ignition switch OFF.

-

Disconnect CVT shift selector harness connector.

-

Check continuity between CVT shift selector terminals as follows.

B2560 starter control relay

B2560 starter control relay

Description

Starter control relay, integrated in IPDM E/R, permits

the starter relay operation when in N or P position. It is

installed in parallel with the starter relay.

DTC Logic

DTC DETECTI ...

B2602 shift position

B2602 shift position

Description

BCM confirms the shift position with the following 2

signals.

CVT selector lever

Speed signal from meter

DTC Logic

DTC DETECTION LOGIC

NOTE:

If ...

Other materials:

Front fog lamp aiming adjustment

Description

PREPARATION BEFORE ADJUSTING

NOTE: For details, refer to the regulations

in your area.

Before performing aiming adjustment, check the following.

Adjust the tire pressure to specification.

Position vehicle and screen on level surface.

Ensure there is no load in vehicle other ...

Key reminder function symptoms

Symptom Table

KEY REMINDER FUNCTION MALFUNCTION

NOTE:

Before performing the diagnosis in the following table, check

"Work flow". Refer to DLK-9, "Work Flow".

If the following symptoms are detected, check systems shown in

the "Diagnosis/service procedure" column

in this or ...

Audio antenna

Location of Antenna

AV control unit

AV control unit antenna feeder

In-line connectors M103, M501

Antenna amp.

Window antenna

Satellite radio antenna feeder

Satellite radio antenna

Window Antenna Repair

ELEMENT CHECK

Attach probe circuit tester (ohm setting) to antenna ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0082