Nissan Maxima Service and Repair Manual: B2602 shift position

Description

BCM confirms the shift position with the following 2 signals.

-

CVT selector lever

-

Speed signal from meter

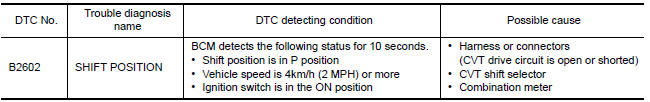

DTC Logic

DTC DETECTION LOGIC

NOTE:

-

If DTC B2602 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to SEC-29, "DTC Logic".

-

If DTC B2602 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to SEC-30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

-

Start the engine under the following conditions and wait for at least 10 seconds.

-

CVT selector lever is in the P or N position

-

Depress the brake pedal.

-

-

Drive the vehicle for at least 10 seconds at a speed greater than 4 km/h (2 MPH).

-

Check "Self diagnostic result" with CONSULT.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-147, "Wiring Diagram" or SEC-128, "Wiring Diagram".

1.CHECK DTC WITH "COMBINATION METER"

Check "Self diagnostic result" with CONSULT. Refer to PCS-27, "DTC Index".

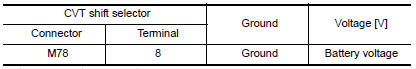

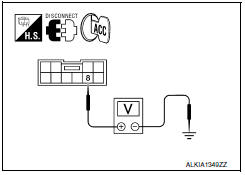

2.CHECK CVT SHIFT SELECTOR POWER SUPPLY

-

Turn ignition switch to ACC.

-

Disconnect CVT shift selector harness connector.

-

Check voltage between CVT shift selector harness connector M78 terminal 8 and ground.

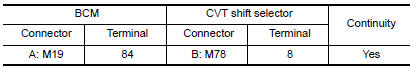

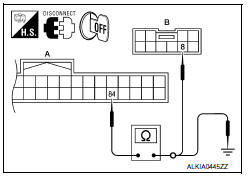

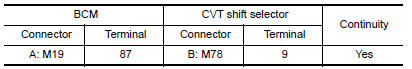

3.CHECK CVT SHIFT SELECTOR POWER SUPPLY CIRCUIT

-

Disconnect BCM harness connector.

-

Check continuity between BCM harness connector M19 (A) terminal 84 and CVT shift selector harness connector M78 (B) terminal 8.

3. Check continuity between BCM harness connector M19 (A) terminal 84 and ground.

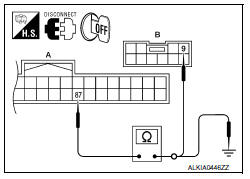

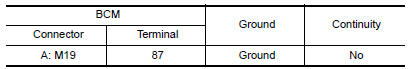

4.CHECK CVT SHIFT SELECTOR CIRCUIT

-

Disconnect BCM harness connector.

-

Check continuity between CVT shift selector harness connector M78 (B) terminal 9 and BCM harness connector M19 (A) terminal 87.

3. Check continuity between BCM harness connector M19 (A) terminal 87 and ground.

5.CHECK CVT SHIFT SELECTOR

Refer to SEC-52, "Component Inspection".

6.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

Inspection End.

B2601 shift position

B2601 shift position

Description

BCM confirms the shift position with the following 2

signals.

CVT selector lever

P position signal from IPDM E/R (CAN)

DTC Logic

DTC DETECTION LOGIC

N ...

B2603 shift position status

B2603 shift position status

Description

BCM confirms the shift position with the following 2

signals.

CVT selector lever

P/N position switch

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC ...

Other materials:

Service data and specifications (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Capacity

Thermostat

Radiator

...

Where to go for service

If maintenance service is required or your vehicle

appears to malfunction, have the systems

checked and serviced. It is recommended that

you visit a NISSAN dealer for this service.

NISSAN technicians are well-trained specialists

and are kept up-to-date with the latest service

information thr ...

Wiring diagram

AUTOMATIC DRIVE POSITIONER

Wiring Diagram

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0082