Nissan Maxima Service and Repair Manual: Precautions in repairing high strength steel

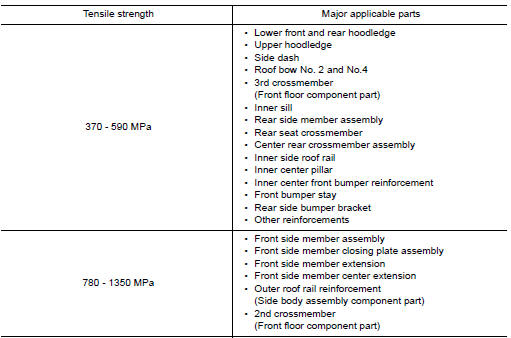

High Strength Steel (HSS)

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

Read the following precautions when repairing HSS:

- Additional points to consider

- The repair of reinforcements (such as side members) by heating

is not recommended since it may weaken the component.

When heating is unavoidable, do not heat HSS parts above 550C (1,022F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropriate.)

- When straightening body panels, use caution in pulling any HSS panel. Because HSS is very strong, pulling may cause deformation in adjacent portions of the body. In this case, increase the number of measuring points, and carefully pull the HSS panel

- When cutting HSS panels, avoid gas (torch) cutting if possible.

Instead, use a saw to avoid weakening surrounding areas due to heat. If gas (torch) cutting is unavoidable, allow a minimum margin of 50 mm (1.97 in).

- When welding HSS panels, use spot welding whenever possible

in order to minimize weakening surrounding areas due to

heat.

If spot welding is impossible, use MIG. welding. Do not use gas (torch) for welding because it is inferior in welding strength.

- The spot weld on HSS panels is harder than that of an ordinary

steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low speed high torque drill (1,000 to 1,200 rpm) to increase drill bit durability and facilitate the operation.

- Precautions in spot welding HSS

This work should be performed under standard working conditions.Always note the following when spot welding HSS:

- The electrode tip diameter must be sized properly according to the metal thickness

- The panel surfaces must fit flush to each other, leaving no gaps.

- Follow the specifications for the proper welding pitch

Body alignment

Body alignment

Body Center Marks

A mark has been placed on each part of the body to indicate the vehicle

center. When repairing parts damaged

by an accident which might affect the vehicle frame (members, pillar ...

Replacement operations

Replacement operations

Description

This section is prepared for technicians who have attained a high level of

skill and experience in repairing collision-

damaged vehicles and also use modern service tools and equipmen ...

Other materials:

P1709 incompleted data writing

Description

When TCM does not store calibration data (individual

characteristic value) of each solenoid valve that is

stored in the ROM assembly (in the control valve), a malfunction is detected.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

Immediately after performing ...

P0011, P0021 IVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0011 or P0021 is displayed with DTC P0075, P0081, first perform the

trouble diagnosis for DTC

P0075, P0081.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the follow ...

Instrument panel assembly

Exploded View

Center speaker grille (if equipped)

Tweeter speaker grille (LH)

Front defroster grille (LH)

Instrument panel

Instrument side finisher (LH)

Lower knee protector (LH)

Instrument lower panel (LH)

Fuse block cover

Steering column lower cover (power tilt)

Ste ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069