Nissan Maxima Service and Repair Manual: Headlamp (HI) circuit

Description

The IPDM E/R (intelligent power distribution module engine room) controls the headlamp high relay based on inputs from the BCM over the CAN communication lines. When the headlamp high relay is energized, power flows through fuses 48 and 49, located in the IPDM E/R. Power then flows to the front combination lamps to the headlamp high beam.

Component Function Check

1.CHECK HEADLAMP (HI) OPERATION

WITHOUT CONSULT

- Start IPDM E/R auto active test. Refer to PCS-11, "Diagnosis Description".

- Check that the headlamp switches to the high beam.

NOTE: HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT

- Select "EXTERNAL LAMPS" of IPDM E/R active test item.

- While operating the test item, check that the headlamp switches to the high beam.

HI : Headlamp switches to the high beam.

OFF : Headlamp OFF

Diagnosis Procedure

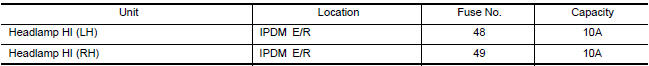

1.CHECK HEADLAMP (HI) FUSES

- Turn the ignition switch OFF.

- Check that the following fuses are not open.

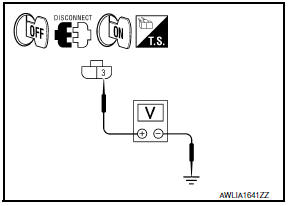

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

CONSULT ACTIVE TEST

- Turn the ignition switch OFF.

- Disconnect the front combination lamp connector.

- Turn the ignition switch ON.

- Select "EXTERNAL LAMPS" of IPDM E/R active test item.

- With EXTERNAL LAMP ON, check the voltage between the combination lamp connector and ground.

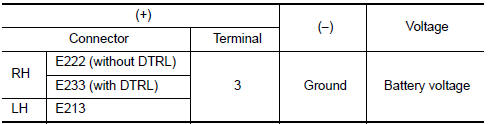

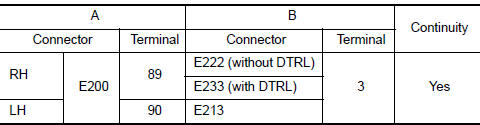

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

- Turn the ignition switch OFF.

- Disconnect IPDM E/R connector E200.

- Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

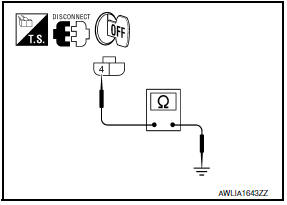

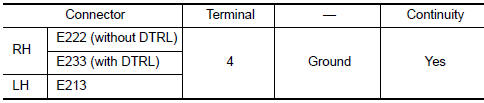

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness connector terminal and ground.

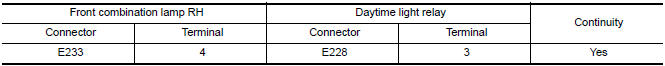

5.CHECK CONTINUITY BETWEEN FRONT COMBINATION LAMP RH (HI) AND DAYTIME LIGHT RELAY

- Disconnect daytime light relay connector.

- Check continuity between front combination lamp RH harness connector and daytime light relay harness connector.

6.CHECK DAYTIME LIGHT RELAY GROUND CIRCUIT

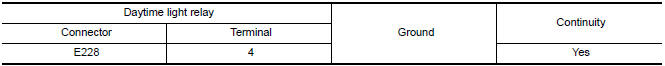

Check continuity between daytime light relay harness connector and ground.

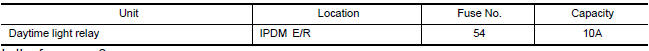

7.CHECK DAYTIME LIGHT RELAY FUSE

- Turn the ignition switch OFF.

- Check that the following fuse is not open.

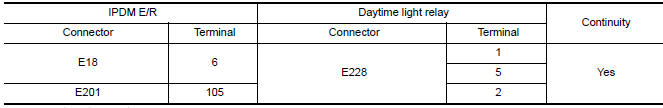

8.CHECK DAYTIME LIGHT RELAY CIRCUIT FOR OPEN

- Disconnect IPDM E/R connector E18 and E201.

- Check continuity between the IPDM E/R harness connector and the daytime light relay harness connector.

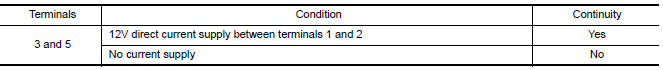

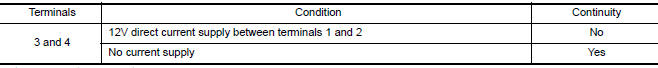

9.CHECK DAYTIME LIGHT RELAY

Check daytime light relay

Component Inspection

1. CHECK DAYTIME LIGHT RELAY

- Turn ignition switch OFF.

- Remove daytime light relay.

- Check the continuity between daytime light relay terminals under the following conditions.

Power supply and ground circuit

Power supply and ground circuit

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis Procedure

1. CHECK FUSE AND FUSIBLE LINK

Check if the following BCM fuses or fusible link are blown.

2. CHECK POWER SUPPLY CIRCU ...

Headlamp (LO) circuit

Headlamp (LO) circuit

Description

The IPDM E/R (intelligent power distribution module engine room) controls the

headlamp low relay based on inputs from the BCM over the CAN communication

lines. When the headlamp low r ...

Other materials:

Tweeter

Description

The AV control unit sends audio signals to the tweeters using the front door

speaker circuits.

Diagnosis Procedure

1.CONNECTOR CHECK

Check the AV control unit and speaker connectors for the following:

Proper connection

Damage

Disconnected or loose terminals

2.HARNESS CHE ...

Three-way catalyst

The three-way catalyst is an emission control

device installed in the exhaust system. Exhaust

gases in the three-way catalyst are burned at

high temperatures to help reduce pollutants.

WARNING

The exhaust gas and the exhaust system

are very hot. Keep people, animals

or flammable material ...

Control unit

Removal and Installation

A/C AND AV SWITCH ASSEMBLY

Removal and Installation

The A/C and AV switch assembly is located in cluster lid C.

Refer to AV-481, "Removal and Installation" (BOSE W/COLOR

DISPLAY).

Refer to AV-652, "Removal and Installation" (BOSE W/COLOR DISPL ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0079