Nissan Maxima Service and Repair Manual: DLC branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

-

Turn the ignition switch OFF.

-

Disconnect the battery cable from the negative terminal.

-

Check the terminals and connectors of the data link connector for damage, bend and loose connection (connector side and harness side).

2.CHECK HARNESS FOR OPEN CIRCUIT

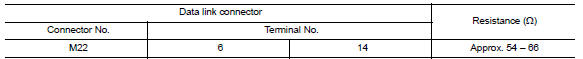

Check the resistance between the data link connector terminals.

BCM branch line circuit

BCM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative

terminal.

Check the terminals and connec ...

M&A branch line circuit

M&A branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the combination meter for

...

Other materials:

ADP branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (unit side and connector

side).

Driver seat control unit

Harness connec ...

P0710 transmission fluid temperature sensor A

Description

The CVT fluid temperature sensor detects the CVT fluid temperature and sends

a signal to the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after performing any "DTC CONFIRMATION

PROCEDURE", alway ...

U1243 display unit

Description

Part name

Description

DISPLAY UNIT

Display image is controlled by the serial communication from AV

control unit.

Inputs the RGB image signal (RGB, RGB area and RGB

synchronizing) from AV control unit and the auxiliary image ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0058