Nissan Maxima Service and Repair Manual: CAN communication circuit

Diagnosis Procedure

1.CONNECTOR INSPECTION

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect all the unit connectors on CAN communication system.

- Check terminals and connectors for damage, bend and loose connection.

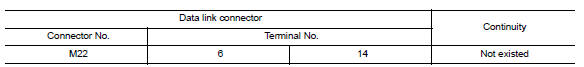

2.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector terminals.

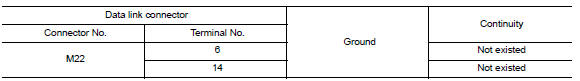

3.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground.

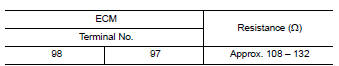

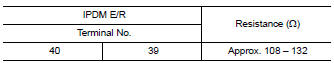

4.CHECK ECM AND IPDM E/R TERMINATION CIRCUIT

- Remove the ECM and the IPDM E/R.

- Check the resistance between the ECM terminals.

3. Check the resistance between the IPDM E/R terminals.

5.CHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in the "Symptom (Results from interview with customer)" are reproduced.

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect one of the unit connectors of CAN communication system.

NOTE: ECM and IPDM E/R have a termination circuit. Check other units first.

- Connect the battery cable to the negative terminal. Check if the

symptoms described in the "Symptom

(Results from interview with customer)" are reproduced.

NOTE: Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

IPDM-E branch line circuit

IPDM-E branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the IPDM E/R for damage,

...

Other materials:

Trunk release solenoid

Description

Performs trunk lid open with signal from BCM.

Component Function Check

1. CHECK TRUNK LID OPENER CANCEL SWITCH

Check trunk lid opener cancel switch position.

2. CHECK FUNCTION

Perform Active Test TRUNK/GLASS HATCH with CONSULT.

Touch "OPEN" and check that trunk lid opens

...

Service data and specifications (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

Brake Pedal

Check Valve

Brake Booster

Front Disc Brake

Rear Disc Brake

...

Front tweeter

Removal and Installation

REMOVAL

Remove the front pillar finisher. Refer to INT-24, "Removal and

Installation".

Remove the front tweeter speaker grille. Refer to IP-10, "Exploded

View".

Remove the front tweeter speaker screws (A).

Pull out front tweeter speaker (1), disconnect the ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0057