Nissan Maxima Service and Repair Manual: IPDM E/R (intelligent power distribution module engine room)

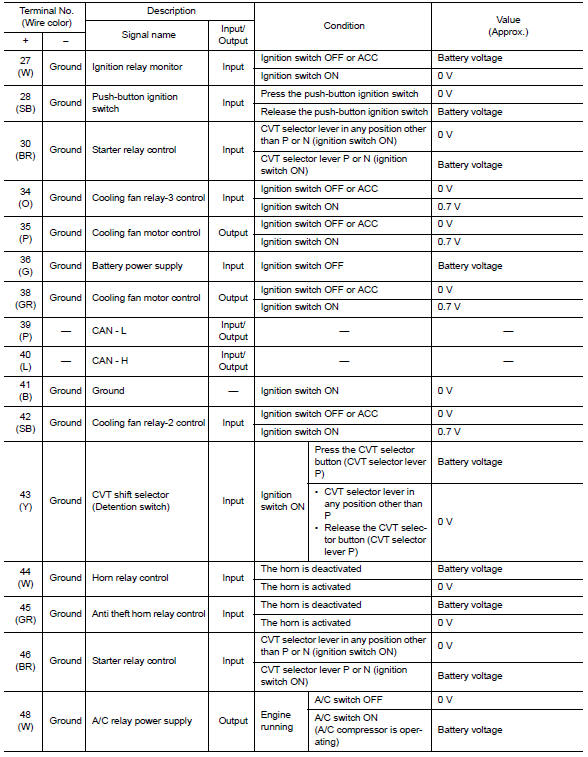

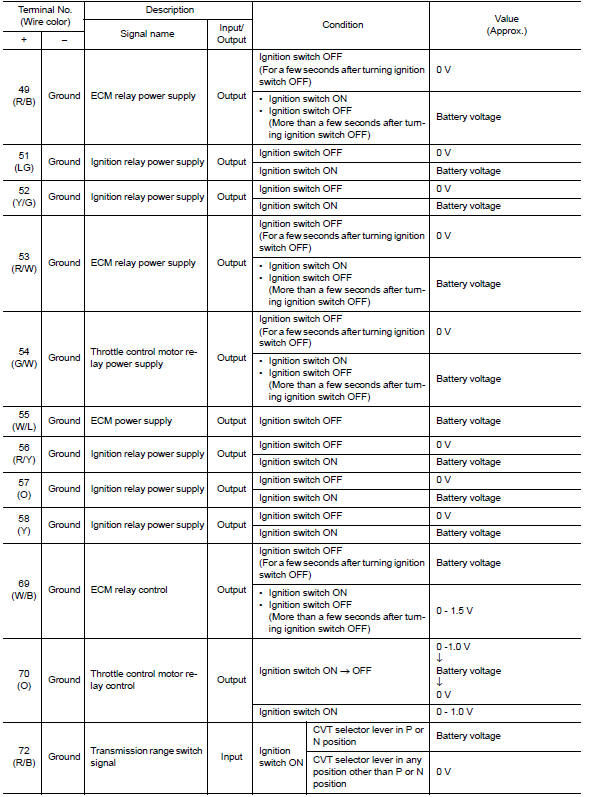

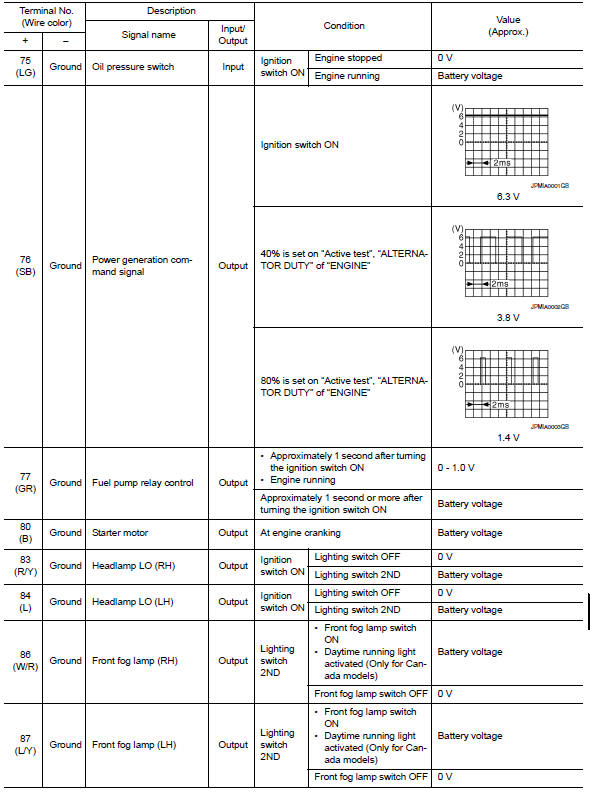

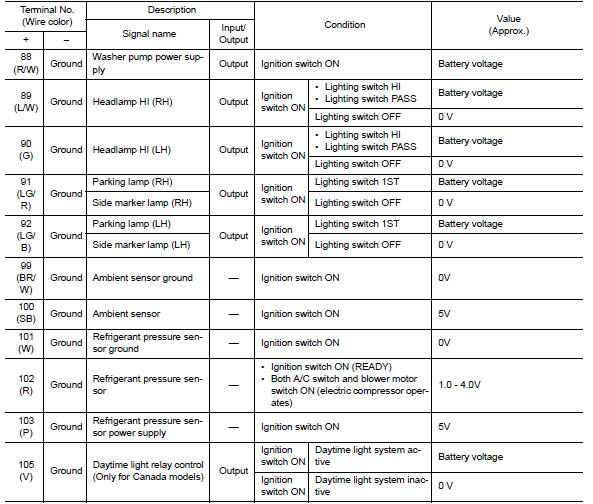

Reference Value

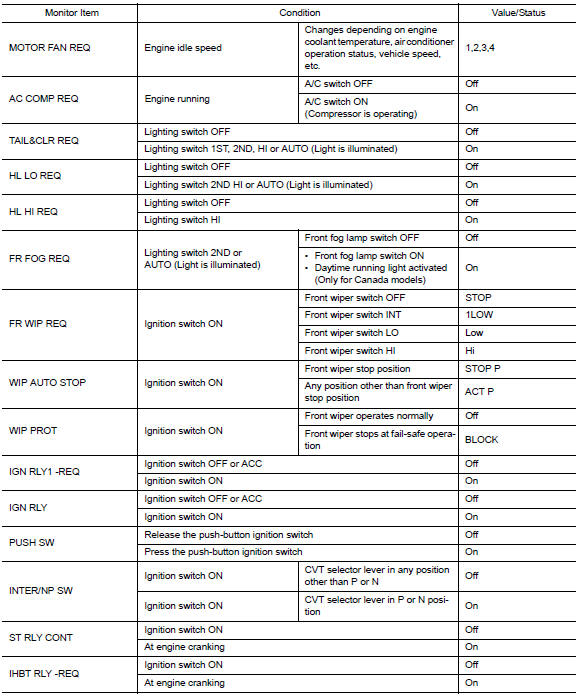

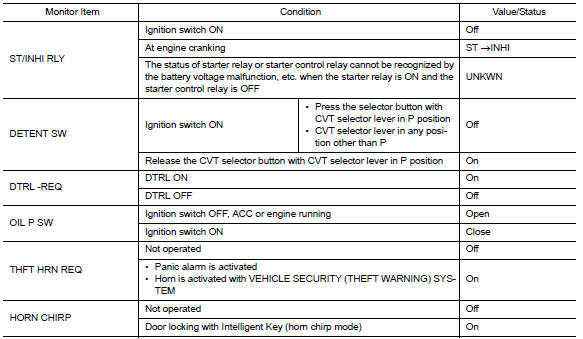

VALUES ON THE DIAGNOSIS TOOL

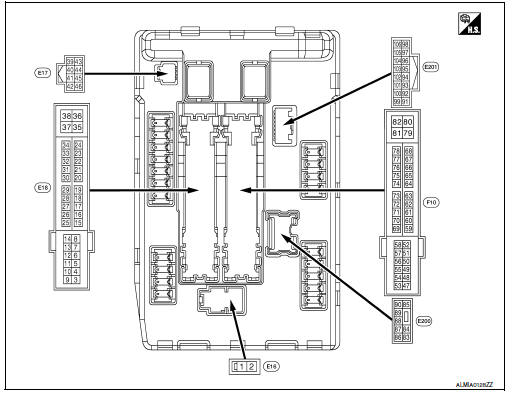

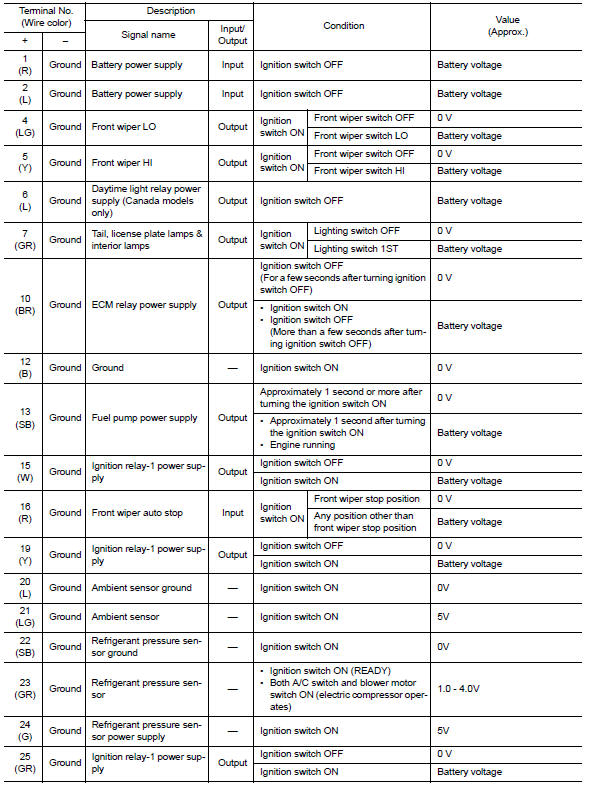

TERMINAL LAYOUT

Fail Safe

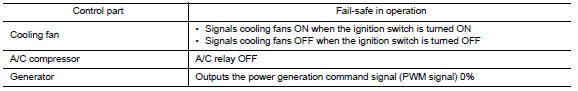

CAN COMMUNICATION CONTROL When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

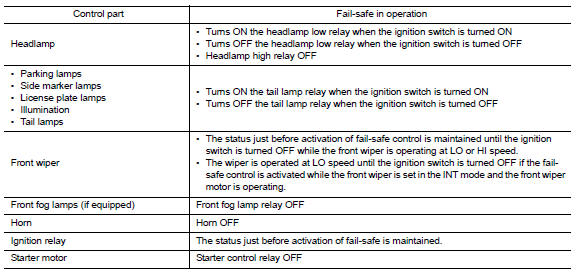

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

-

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay-1 inside it.

-

IPDM E/R judges the ignition relay-1 error if the voltage differs between the contact circuit and the excitation coil circuit.

-

If the ignition relay-1 cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay-1 malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

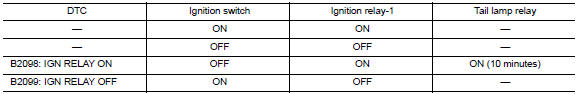

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper after repeating a front wiper 10 seconds activation and 20 seconds stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R "Data Monitor" that displays "BLOCK" for the item "WIP PROT" while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains active for 90 seconds.

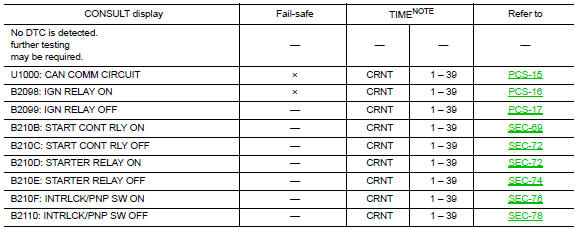

DTC Index

NOTE:

-

The details of TIME display are as follows.

CRNT: The malfunctions that are detected now

-

1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It increases like 0 → 1 → 2 ··* 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is detected again in the process.

BCM (body control module)

BCM (body control module)

Reference Value

NOTE:

The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and dis ...

Wiring diagram

Wiring diagram

...

Other materials:

Drive mode selector

Drive mode selector switches

Two driving modes can be selected by using the

drive mode selector switches, NORMAL and

SPORT.

NOTE:

When the drive mode select switch selects a

mode, the mode may not switch quickly. This

is not a malfunction.

Select the NORMAL mode for normal driving. ...

In-vehicle sensor

Removal and Installation

REMOVAL

Remove the instrument lower panel LH. Refer to IP-19, "Removal and

Installation".

Remove the in-vehicle sensor screw and the in-vehicle sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Make sure that the asp ...

TCM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (unit side and connector

side).

TCM

Harness connector F1

Harness con ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.007