Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

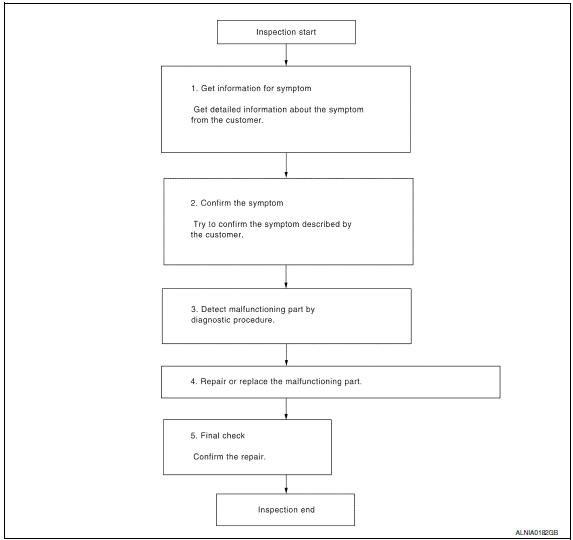

Work Flow

OVERALL SEQUENCE

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred).

2.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer. Verify relation between the symptom and the condition when the symptom is detected.

3.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

4.REPAIR OR REPLACE THE MALFUNCTIONING PART

- Repair or replace the malfunctioning part.

- Reconnect parts or connectors disconnected during Diagnostic Procedure.

5.FINAL CHECK

Refer to confirmed symptom in step 2, and make sure that the symptom is not detected.

Bluetooth control unit

Bluetooth control unit

Removal and Installation

REMOVAL

Disconnect the battery negative terminal. Refer to PG-67, "Removal

and Installation (Battery)".

Remove the trunk upper finisher. Refer to INT-23, "Exploded ...

Other materials:

Trunk release solenoid

Description

Performs trunk lid open with signal from BCM.

Component Function Check

1. CHECK TRUNK LID OPENER CANCEL SWITCH

Check trunk lid opener cancel switch position.

2. CHECK FUNCTION

Perform Active Test TRUNK/GLASS HATCH with CONSULT.

Touch "OPEN" and check that trunk lid opens

...

Emission control system maintenance

Abbreviations: I = Inspect and correct or replace as necessary, R =

Replace, D = Drain water

NOTE:

(1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000

miles (16,000 km) or 12 months. Replace the drive belts if found

damaged.

(2) If operating mainly in dusty condit ...

Avoiding collision and rollover

WARNING

Failure to operate this vehicle in a safe

and prudent manner may result in loss of

control or an accident.

Be alert and drive defensively at all times. Obey

all traffic regulations. Avoid excessive speed,

high speed cornering, or sudden steering maneuvers,

because these driving practi ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0055