Nissan Maxima Owners Manual: Checking tire pressure

1. Remove the valve stem cap from the tire.

2. Press the pressure gauge squarely onto the valve stem. Do not press too hard or force the valve stem sideways, or air will escape. If the hissing sound of air escaping from the tire is heard while checking the pressure, reposition the gauge to eliminate this leakage.

3. Remove the gauge.

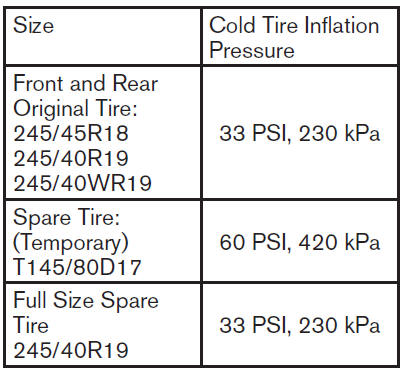

4. Read the tire pressure on the gauge stem and compare to the specification shown on the Tire and Loading Information label.

5. Add air to the tire as needed. If too much air is added, press the core of the valve stem briefly with the tip of the gauge stem to release pressure.

Recheck the pressure and add or release air as needed.

6. Install the valve stem cap.

7. Check the pressure of all other tires,

including the spare.

Tire and loading information label

Tire and loading information label

Seating capacity: The maximum number

of occupants that can be seated

in the vehicle.

Vehicle load limit: Refer to the loading

information in the "Technical and

consumer information" s ...

Tire labeling

Tire labeling

Example

Federal law requires tire manufacturers to

place standardized information on the

sidewall of all tires. This information identifies

and describes the fundamental

characteristics of the ...

Other materials:

Precaution

PRECAUTIONS

Precautions for Trouble Diagnosis

CAUTION:

Never apply 7.0 V or more to the measurement terminal.

Use a tester with open terminal voltage of 7.0 V or less.

Turn the ignition switch OFF and disconnect the battery cable from the

negative terminal when checking the harness.

P ...

P1701 TCM

Description

When the power supply to the TCM is cut off, for example

because the battery is removed, and the self-diagnosis

memory function stops, a malfunction is detected.

NOTE:

Since "P1701" is indicated when replacing TCM, perform diagnosis after erasing

"Self Diagnostic Results".

DTC ...

ECU diagnosis information

BCM (BODY CONTROL MODULE)

Reference Value

NOTE: The Signal Tech II Tool (J-50190) can

be used to perform the following functions. Refer to the Signal Tech II User

Guide for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS transm ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0102