Nissan Maxima Service and Repair Manual: Compression Pressure

On-Vehicle Service

CHECKING COMPRESSION PRESSURE

- Run the engine until it reaches normal operating temperature.

- Turn the ignition switch to OFF.

- Release fuel pressure. Refer to EC-592, "Inspection".

- Remove all six spark plugs.

Refer to EM-12, "Removal and Installation".

- Attach a compression tester to No. 1 cylinder.

- Depress accelerator pedal fully to keep the electric throttle control actuator butterfly-valve wide open to maximize air intake flow.

- Crank the engine and record the highest gauge indication.

- Repeat the measurement on each cylinder (steps 5 - 7).

- Always use a fully-charged battery to obtain specified engine speed.

- If the engine speed is out of the specified range check the battery and recharge as necessary. Check the engine speed again with the battery properly charged.

- If some cylinders have low compression pressure, pour a small amount of engine oil into the spark plug hole of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check the piston rings and replace if necessary

- If the compression pressure remains at low level despite the addition of engine oil, the valves may be malfunctioning. Check the valves for damage. Replace the valve or valve seat accordingly.

- If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, cylinder head gaskets may be leaking, or a valve in adjacent cylinders may be damaged. Inspect and repair as required.

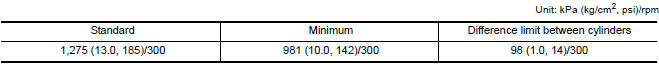

- If the compression pressure is below the minimum value, check the valve clearances and parts associated with the combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head gasket). After the checking, measure the compression pressure again.

Camshaft Valve Clearance

Camshaft Valve Clearance

Valve Clearance

CHECKING

NOTE:

Perform inspection as follows after removal, installation or

replacement of camshaft or valve related parts, or if there are unusual

engine conditions rega ...

Other materials:

Roof finisher

Removal and Installation

REMOVAL

Open the glass lid.

Apply protective tape around the roof side finisher to protect the

surface from damage.

Cut adhesive.

Pass piano wire through the adhesive with a wire pierce.

Tie piano wire on both ends to assist in wire grip.

Pull piano wir ...

Glove box assembly

Removal and Installation

REMOVAL

Using a suitable tool, gently remove the instrument panel side

finisher (RH).

Open the glove box door and then remove the glove box assembly

screws (A).

Remove the glove box assembly lower screws (A).

Disconnect the harness connectors, then rem ...

C1121, C1123, C1125, C1127 out ABS sol

Description

The solenoid valve increases, holds or decreases the fluid pressure of each

brake caliper according to the signals

transmitted by the ABS actuator and electric unit (control unit).

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Check ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069