Nissan Maxima Service and Repair Manual: Electric ignition system

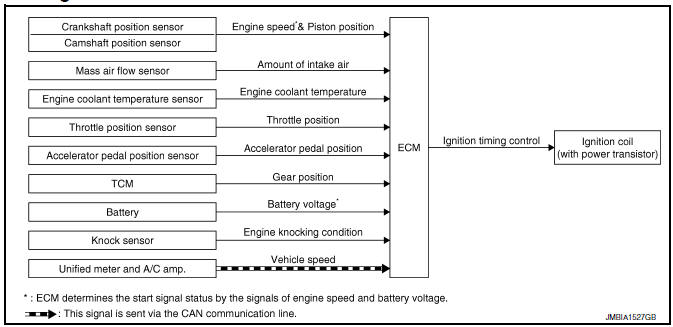

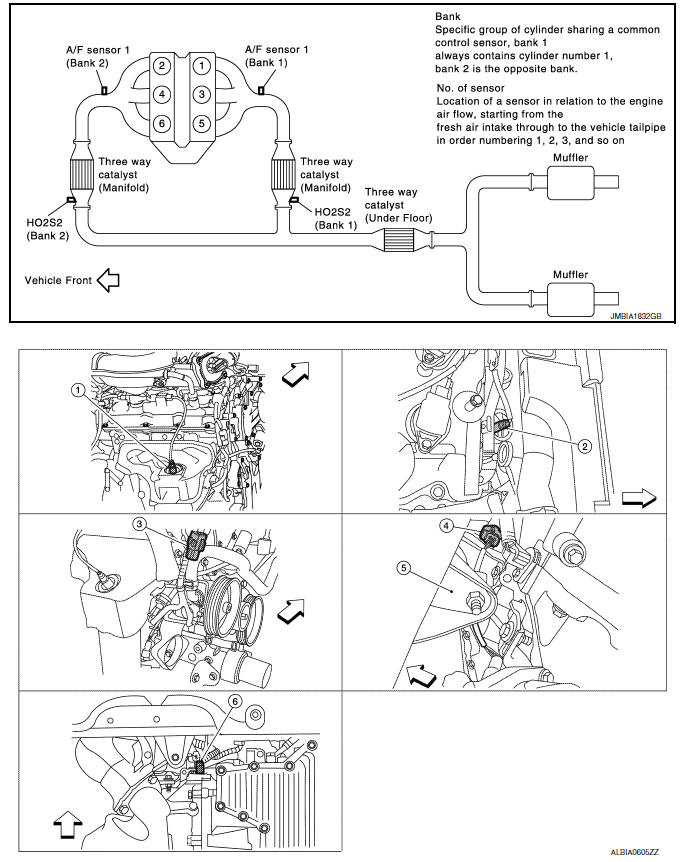

System Diagram

System Description

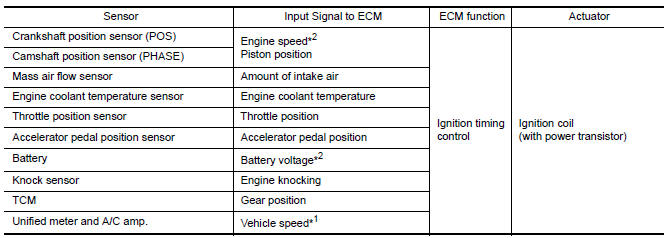

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and

battery voltage.

SYSTEM DESCRIPTION

Ignition order: 1 - 2 - 3 - 4 - 5 - 6

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor (PHASE) signal.

Computing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in the ECM.

- At starting

- During warm-up

- At idle

- At low battery voltage

- During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

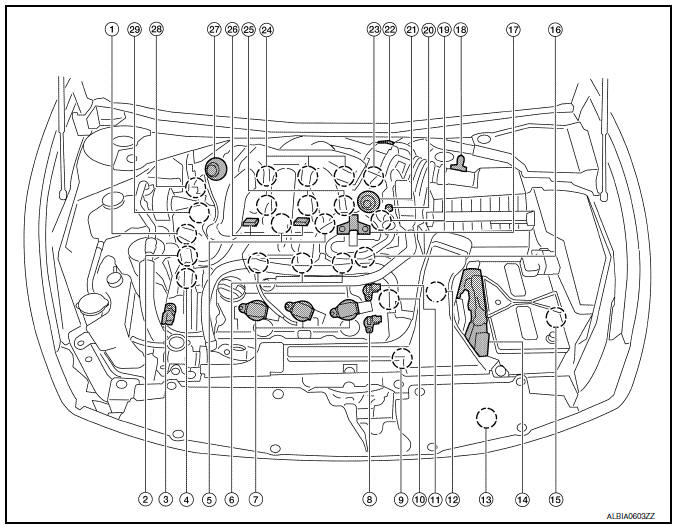

Component Parts Location

- Intake valve timing control solenoid valve (bank 1)

- Electronic controlled engine mount control solenoid valve

- Exhaust valve timing control magnet retarder (bank 2)

- Intake valve timing control solenoid valve (bank 2)

- Knock sensor (bank 1 and 2)

- Fuel injector (bank 2)

- Ignition coil (with power transistor) and spark plug (bank 2)

- Exhaust valve timing control position sensor (bank 2)

- Crankshaft position sensor (POS)

- Engine coolant temperature sensor

- Camshaft position sensor (PHASE) (bank 2)

- Transmission range switch

- Refrigerant pressure sensor

- ECM

- Battery current sensor

- . Condenser-2

- EVAP canister purge volume control solenoid valve

- Mass air flow sensor (with intake air temperature sensor)

- Camshaft position sensor (PHASE) (bank 1)

- EVAP service port

- Power valve actuator 2

- Electric throttle control actuator

- Exhaust valve timing control position sensor (bank 1)

- Ignition coil (with power transistor) and spark plug (bank 1)

- Fuel injector (bank 1)

- VIAS control solenoid valve 1 and 2

- Power valve actuator 1

- Exhaust valve timing control magnet retarder (bank 1)

- Power steering pressure sensor

- Mas air flow sensor (with intake air temperature sensor)

- Air cleaner case

- Engine coolant temperature sensor (view with engine cover removed)

- EVAP canister purge volume control solenoid valve (view with engine cover removed)

- Power valve actuator 1 (view with engine cover removed)

- VIAS control solenoid valve 1

- VIAS control solenoid valve 2

- Power valve actuator 2

- Power steering pressure sensor

- Tie rod (RH)

- Camshaft position sensor (PHASE) (bank 1) (view with air cleaner case removed)

- Exhaust valve timing control position sensor (bank 1)

- Camshaft position sensor (PHASE) (bank 2) (view with air cleaner case removed)

- Exhaust valve timing control position sensor (bank 2)

- Engine oil temperature sensor

: Vehicle front

: Vehicle front

- A/F sensor 1 (bank 1) (view with engine removed)

- A/F sensor 1 (bank 2)

- HO2S2 (bank 1) harness connector (view with engine removed)

- HO2S2 (bank 2) harness connector

- Front engine mount

- Crankshaft position sensor (POS)

: Vehicle front

: Vehicle front

- Electronic controlled engine mount control solenoid valve (view with engine cover removed)

- EVAP control system pressure sensor (view with rear suspension member removed)

- EVAP canister vent control valve

- EVAP canister

- Fuel injector harness connector (view with intake manifold collector removed)

- Exhaust valve timing control magnet retarder (bank 1) (view with engine removed)

- Intake valve timing control solenoid valve (bank 1)

- Intake valve timing control solenoid valve (bank 2)

- Exhaust valve timing control magnet

retarder (bank 2)

: Vehicle front

: Vehicle front

- Knock sensor (bank 2) (view with intake manifold removed)

- Knock sensor (bank 1)

- Transmission range switch (view with CVT removed)

- Battery

- IPDM E/R

- ECM

- Refrigerant pressure sensor (view with front grille removed)

- Accelerator pedal position sensor

: Vehicle front

: Vehicle front

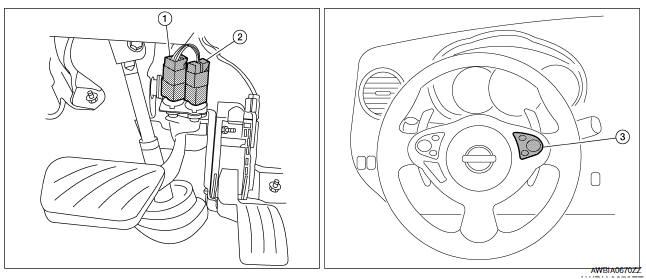

- Stop lamp switch

- ASCD brake switch

- ASCD steering switch

Component Description

Component Reference

- Accelerator pedal position sensor EC-467, "Description"

- Camshaft position sensor (PHASE) EC-300, "Description"

- Crankshaft position sensor (POS) EC-296, "Description"

- Engine coolant temperature sensor EC-201, "Description"

- Ignition signal EC-502, "Description"

- Knock sensor EC-293, "Description"

- Mass air flow sensor EC-183, "Description"

- TCM EC-397, "Description"

- Throttle position sensor

Multiport fuel injection system

Multiport fuel injection system

System Diagram

System Description

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to control the engine system under normal

conditions.

*2: This signal is sent to the ECM via the ...

Air conditioning cut control

Air conditioning cut control

System Diagram

System Description

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of ...

Other materials:

NISSAN vehicle immobilizer system-nats symptoms

Symptom Table

Security indicator does not turn ON or flash.

CAUTION:

Follow Trouble Diagnosis Flowchart

referring to "SEC-4, "Work Flow"". Determine malfunctioning

condition before performing this diagnosis.

Check that vehicle is under the

condition shown in "Co ...

ECU diagnosis information

A/C AUTO AMP.

Reference Value

VALUES ON THE DIAGNOSIS TOOL

CONSULT MONITOR ITEM

A/C AUTO AMP. HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR A/C AUTO AMP.

DTC Inspection Priority Chart

If some DTCs are displayed at the same time, perform inspections one b ...

Extended storage switch

The extended storage switch is used when the

vehicle is in transit from the factory. It is located in

the fuse panel to the left of the steering wheel on

the instrument panel. If any electrical equipment

does not operate, ensure the extended storage

switch is pushed fully in place, as shown ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0075