Nissan Maxima Service and Repair Manual: Exhaust valve timing control

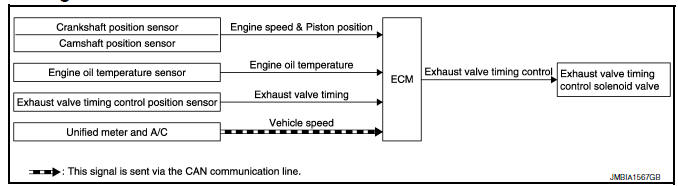

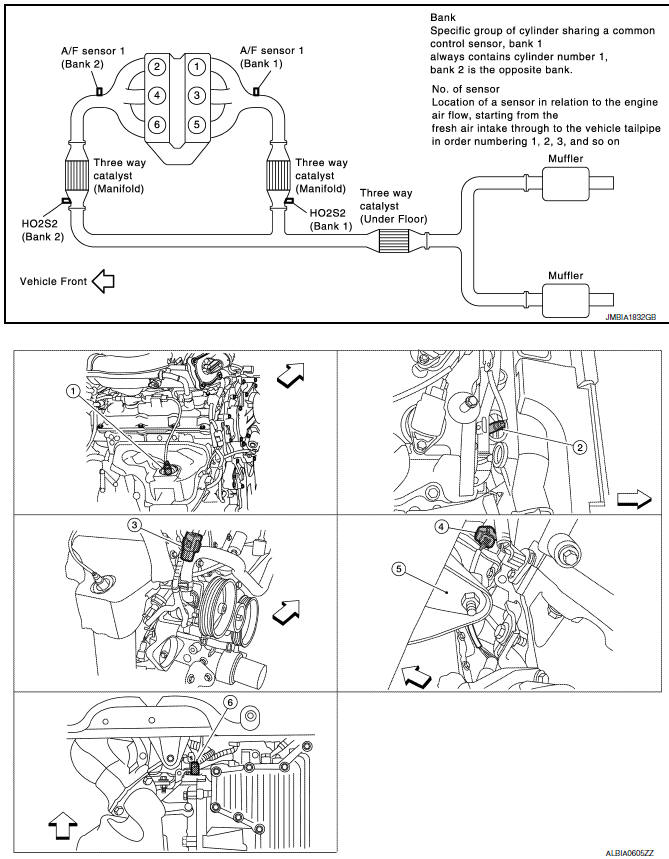

System Diagram

System Description

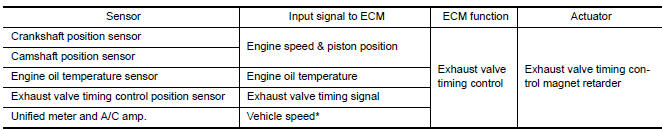

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM via the CAN Communication line.

SYSTEM DESCRIPTION

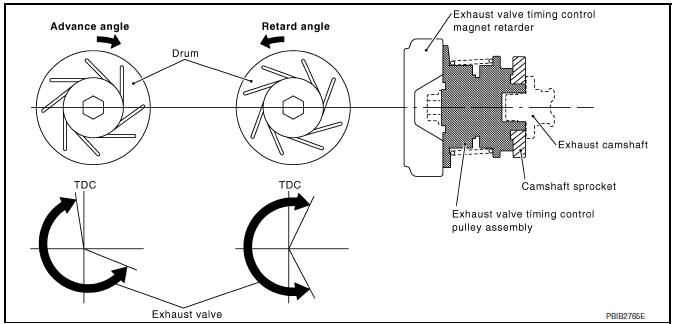

This mechanism magnetically controls cam phases continuously with the fixed operating angle of the exhaust valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine oil temperature.

Then, the ECM sends ON/OFF pulse duty signals to the exhaust valve timing control magnet retarder depending on driving status. This makes it possible to control the shut/open timing of the exhaust valve to increase engine torque and output in a range of high engine speed.

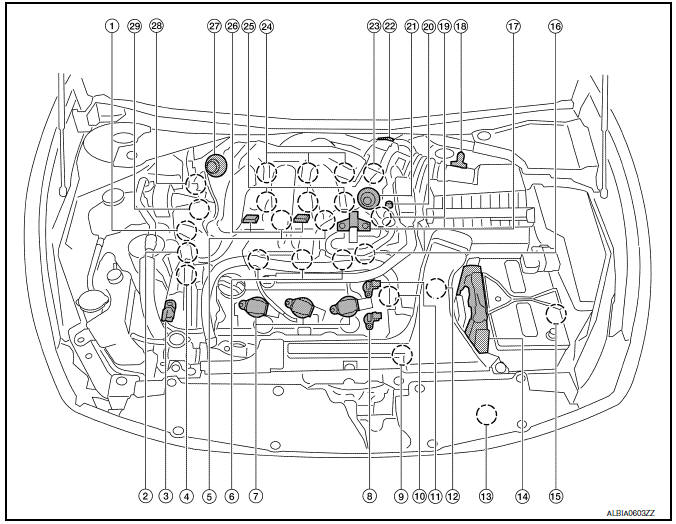

Component Parts Location

- Intake valve timing control solenoid valve (bank 1)

- Electronic controlled engine mount control solenoid valve

- Exhaust valve timing control magnet retarder (bank 2)

- Intake valve timing control solenoid valve (bank 2)

- Knock sensor (bank 1 and 2)

- Fuel injector (bank 2)

- Ignition coil (with power transistor) and spark plug (bank 2)

- Exhaust valve timing control position sensor (bank 2)

- Crankshaft position sensor (POS)

- Engine coolant temperature sensor

- Camshaft position sensor (PHASE) (bank 2)

- Transmission range switch

- Refrigerant pressure sensor

- ECM

- Battery current sensor

- Condenser-2

- EVAP canister purge volume control solenoid valve

- Mass air flow sensor (with intake air temperature sensor)

- Camshaft position sensor (PHASE) (bank 1)

- EVAP service port

- Power valve actuator 2

- Electric throttle control actuator

- Exhaust valve timing control position sensor (bank 1)

- Ignition coil (with power transistor) and spark plug (bank 1)

- Fuel injector (bank 1)

- VIAS control solenoid valve 1 and 2

- Power valve actuator 1

- Exhaust valve timing control magnet retarder (bank 1)

- Power steering pressure sensor

- Mas air flow sensor (with intake air temperature sensor)

- Air cleaner case

- Engine coolant temperature sensor (view with engine cover removed)

- EVAP canister purge volume control solenoid valve (view with engine cover removed)

- Power valve actuator 1 (view with engine cover removed)

- VIAS control solenoid valve 1

- VIAS control solenoid valve 2

- Power valve actuator 2

- Power steering pressure sensor

- Tie rod (RH)

- Camshaft position sensor (PHASE) (bank 1) (view with air cleaner case removed)

- Exhaust valve timing control position sensor (bank 1)

- Camshaft position sensor (PHASE) (bank 2) (view with air cleaner case removed)

- Exhaust valve timing control position sensor (bank 2)

- Engine oil temperature sensor

: Vehicle front

: Vehicle front

- A/F sensor 1 (bank 1) (view with engine removed)

- A/F sensor 1 (bank 2)

- HO2S2 (bank 1) harness connector (view with engine removed)

- HO2S2 (bank 2) harness connector

- Front engine mount

- Crankshaft position sensor (POS)

: Vehicle front

: Vehicle front

- Electronic controlled engine mount control solenoid valve (view with engine cover removed)

- EVAP control system pressure sensor (view with rear suspension member removed)

- EVAP canister vent control valve

- EVAP canister

- Fuel injector harness connector (view with intake manifold collector removed)

- Exhaust valve timing control magnet retarder (bank 1) (view with engine removed)

- Intake valve timing control solenoid valve (bank 1)

- Intake valve timing control solenoid valve (bank 2)

- Exhaust valve timing control magnet

retarder (bank 2)

: Vehicle front

: Vehicle front

- Knock sensor (bank 2) (view with intake manifold removed)

- Knock sensor (bank 1)

- Transmission range switch (view with CVT removed)

- Battery

- IPDM E/R

- ECM

- Refrigerant pressure sensor (view with front grille removed)

- Accelerator pedal position sensor

: Vehicle front

: Vehicle front

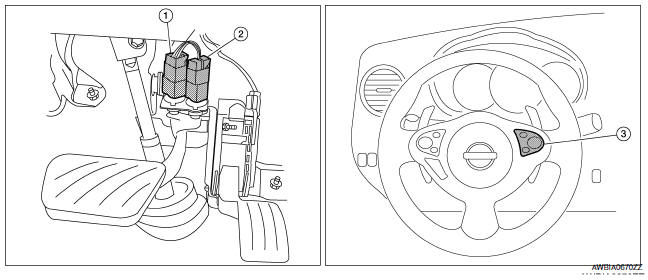

- Stop lamp switch

- ASCD brake switch

- ASCD steering switch

Component Description

Component Reference

- Camshaft position sensor EC-300, "Description"

- Crankshaft position sensor EC-296, "Description"

- Engine oil temperature sensor EC-277, "Description"

- Exhaust valve timing control magnet retarder EC-180, "Description"

- Exhaust valve timing control position sensor

Evaporative emission system

Evaporative emission system

System Diagram

System Description

*1: ECM determines the start signal status by the signals of engine speed and

battery voltage.

*2: This signal is sent to the ECM via the CAN communicat ...

Intake valve timing control

Intake valve timing control

System Diagram

System Description

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM via the CAN communication line

SYSTEM DESCRIPTION

This mechanism hydraulically controls c ...

Other materials:

Intelligent key interlock function

INTELLIGENT KEY INTERLOCK FUNCTION : System

INTELLIGENT KEY INTERLOCK FUNCTION : System Description

OUTLINE

When unlocking doors by using Intelligent Key or door request switch (driver

side), seat slide and steering tilt move directly to the exit assist

function.

Other loads move to the ...

Symptom diagnosis

AUDIO SYSTEM

Symptom Table

AUDIO SYSTEM

Symptoms

Check items

Probable malfunction location

The disk cannot be removed.

Audio unit

Malfunction in audio unit.

Refer to AV-73, "Removal and

Installation".

No sound comes out ...

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW\

1.CHECK SYMPTOM

Check the malfunction symptoms by performing the following items.

Interview the customer to obtain the malfunction information

(conditions and environment when the malfunction occurred).

Check the symptom.

2.SELF-DIAGNOSIS ( ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0079