Nissan Maxima Service and Repair Manual: Power supply and ground circuit

Diagnosis Procedure

1.CHECK GROUND CONNECTION-I

- Turn ignition switch OFF.

- Check ground connection E9. Refer to Ground Inspection

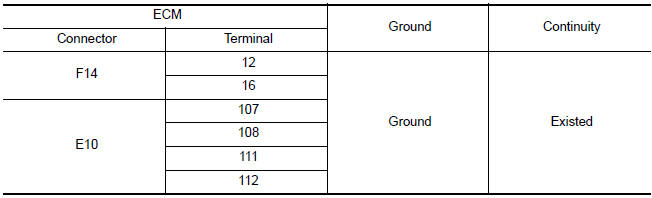

2.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

- Disconnect ECM harness connector.

- Check the continuity between ECM harness connector and ground.

- Also check harness for short to power.

3.DETECT MALFUNCTIONING PART

Check the following.

- Harness connectors E11, F2

- Harness for open or short between ECM and ground

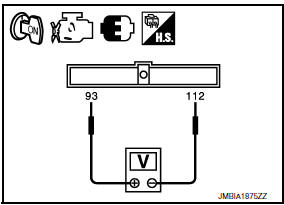

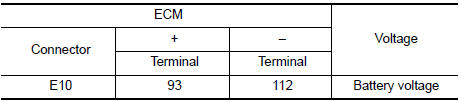

4.CHECK ECM POWER SUPPLY CIRCUIT-I

- Reconnect ECM harness connector.

- Turn ignition switch OFF and then ON.

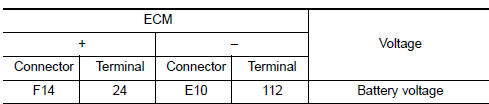

- Check the voltage between ECM harness connectors.

5.DETECT MALFUNCTIONING PART

Check the following.

- IPDM E/R connector E18

- 10 A fuse (No. 35)

- Harness for open or short between ECM and fuse

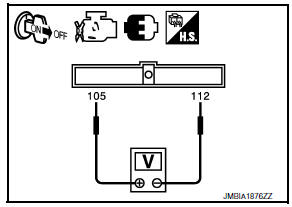

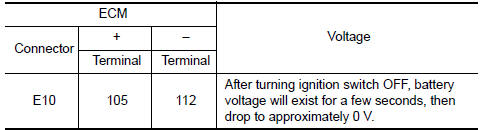

6.CHECK ECM POWER SUPPLY CIRCUIT-II

- Turn ignition switch OFF and wait at least 10 seconds.

- Check the voltage between ECM harness connectors.

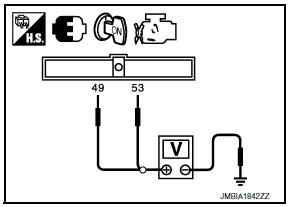

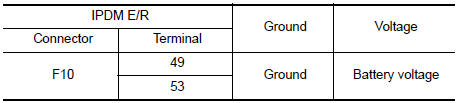

7.CHECK ECM POWER SUPPLY CIRCUIT-III

- Turn ignition switch ON.

- Check the voltage between IPDM E/R harness connector and ground.

8.CHECK INTERMITTENT INCIDENT

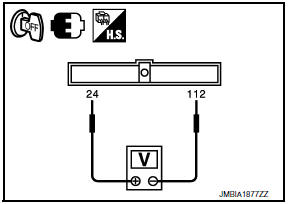

9.CHECK ECM POWER SUPPLY CIRCUIT-IV

- Turn ignition switch OFF and wait at least 10 seconds.

- Check the voltage between ECM harness connectors.

10.CHECK ECM POWER SUPPLY CIRCUIT-V

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

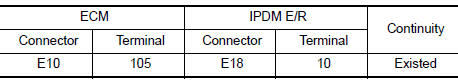

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and short to power.

11.CHECK 15 A FUSE

- Disconnect 15 A fuse (No. 42) from IPDM E/R.

- Check 15 A fuse.

12.CHECK ECM POWER SUPPLY CIRCUIT-VI

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and short to power.

13.DETECT MALFUNCTIONING PART

Check the following.

- Junction block connectors E44, E45

- Harness for open or short between ECM and IPDM E/R

14.CHECK INTERMITTENT INCIDENT

Trouble diagnosis - specification value

Trouble diagnosis - specification value

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in "SPEC" of "DATA MONITOR"

mode of CONSULT during normal operation of the Engine Control System. W ...

U0101 can comm circuit

U0101 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excelle ...

Other materials:

Service Data And Specifications (SDS)

General Specification

GENERAL SPECIFICATIONS

Drive Belt

DRIVE BELT

Spark Plug

SPARK PLUG

*: Always check with the Parts Department for the latest parts information.

Intake Manifold

INTAKE MANIFOLD

Exhaust Manifold

EXHAUST MANIFOLD

Camshaft

CAMSHAFT

*1: Cam wear limit * ...

Vehicle load capacity

Do not exceed the load limit of your vehicle

shown as "The combined weight of

occupants and cargo" on the Tire and

Loading Information label. Do not exceed

the number of occupants shown as

"Seating Capacity" on the Tire and Loading

Information label.

To get "the combined weight of occupants ...

Steering switch

Removal and Installation

REMOVAL

Remove the driver airbag module. Refer to SR-12, "Removal and

Installation".

Remove the steering wheel audio control switch screws (A).

Release the steering wheel audio control switch harness clips

(B).

Remove the steering wheel audio contr ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.012