Nissan Maxima Service and Repair Manual: P0327, P0328, P0332, P0333 KS

Description

The knock sensor is attached to the cylinder block. It senses engine knocking using a piezoelectric element. A knocking vibration from the cylinder block is sensed as vibrational pressure. This pressure is converted into a voltage signal and sent to the ECM.

DTC Logic

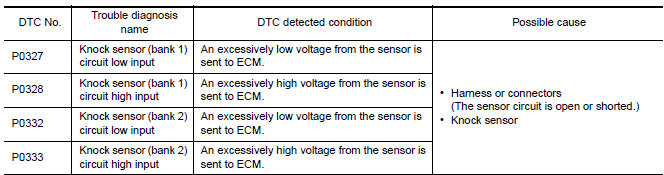

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 10 V at idle.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and run it for at least 5 seconds at idle speed.

- Check 1st trip DTC.

Diagnosis Procedure

1.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9.

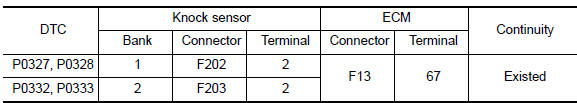

2.CHECK KNOCK SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

- Disconnect knock sensor harness connector and ECM harness connector.

- Check the continuity between knock sensor harness connector and ECM harness connector

- Also check harness for short to ground and short to power.

3.DETECT MALFUNCTIONING PART

Check the following.

- Harness connectors F69, F201

- Harness for open or short between knock sensor and ECM

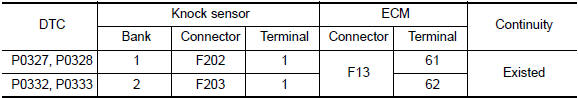

4.CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Check the continuity between knock sensor harness connector and ECM harness connector.

- Also check harness for short to ground and short to power

5.DETECT MALFUNCTIONING PART

Check the following.

- Harness connectors F69, F201

- Harness for open or short between knock sensor and ECM

6.CHECK KNOCK SENSOR

7.CHECK INTERMITTENT INCIDENT

Component Inspection

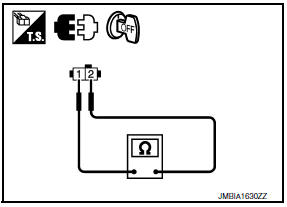

1.CHECK KNOCK SENSOR

- Turn ignition switch OFF.

- Disconnect knock sensor harness connector.

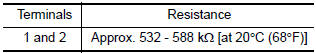

- Check resistance between knock sensor terminal as per the following. NOTE: It is necessary to use an ohmmeter which can measure more than 10 MΩ.

CAUTION: Never use any knock sensors that have been dropped or physically damaged. Use only new ones.

P0300, P0301, P0302, P0303, P0304, P0305, P0306 misfire

P0300, P0301, P0302, P0303, P0304, P0305, P0306 misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM ca ...

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

Description

The crankshaft position sensor (POS) is located on the oil pan facing

the gear teeth (cogs) of the signal plate. It detects the fluctuation of

the engine revolution.

The sensor ...

Other materials:

CAN communication circuit

Diagnosis Procedure

1.CONNECTOR INSPECTION

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect all the unit connectors on CAN communication system.

Check terminals and connectors for damage, bend and loose

connection.

2.CHECK HARNESS CON ...

Front door speaker

Removal and Installation

REMOVAL

Remove the front door finisher. Refer to INT-18, "Removal and

Installation".

Remove the front door speaker screws (A).

Disconnect the harness connector from the front door speaker

(1) and remove.

Remove the front door speaker spacer screws (B) and ...

B1033 - B1035 crash zone sensor

Description

DTC B1033 - B1035 CRASH ZONE SENSOR

The crash zone sensor is wired to the air bag diagnosis sensor unit. The air

bag diagnosis sensor unit willmonitor for opens and shorts in detected lines

to the crash zone sensor.

PART LOCATION

DTC Logic

DTC DETECTION LOGIC

With CONSULT

DT ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0076