Nissan Maxima Service and Repair Manual: P1217 engine over temperature

DTC Logic

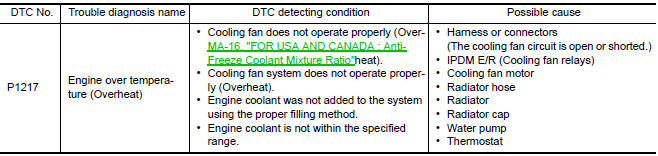

DTC DETECTION LOGIC

NOTE:

- If DTC P1217 is displayed with DTC UXXXX, first perform the

trouble diagnosis for DTC UXXXX.

Refer to EC-161, "DTC Logic".

- If DTC P1217 is displayed with DTC P0607, first perform the trouble diagnosis for DTC P0607. Refer to EC-393, "DTC Logic".

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is indicated.

CAUTION: When a malfunction is indicated, always replace the coolant. Refer to CO-10, "System Inspection".

Also, replace the engine oil. Refer to MA-23, "ENGINE OIL : Changing Engine Oil".

- Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Always use coolant with the proper mixture ratio. Refer to MA-16, "FOR USA AND CANADA : Anti-Freeze Coolant Mixture Ratio" (For NORTH AMERICA) or MA-17, "FOR MEXICO : Engine Coolant Mixture Ratio" (For MEXICO).

- After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-406, "Component Function Check".

NOTE: Use component function check to check the overall function of the cooling fan. During this check, a DTC might not be confirmed.

Component Function Check

1.PERFORM COMPONENT FUNCTION CHECK-I

WARNING: Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pressure fluid escaping from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up pressure to escape. Then turn the cap all the way off.

Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

2.PERFORM COMPONENT FUNCTION CHECK-II

Confirm whether customer filled the coolant or not.

3.PERFORM COMPONENT FUNCTION CHECK-III

With CONSULT

- Turn ignition switch ON.

- Perform "COOLING FAN" in "ACTIVE TEST" mode with CONSULT.

- Check that cooling fan motors-1 and -2 operate at each speed (LOW/MID/HI).

Without CONSULT

Perform IPDM E/R auto active test and check cooling fan motors operation

Diagnosis Procedure

1.CHECK COOLING FAN OPERATION

With CONSULT

- Turn ignition switch ON.

- Perform "COOLING FAN" in "ACTIVE TEST" mode with CONSULT.

- Check that cooling fans-1 and -2 operate at each speed (LOW/MID/HI).

Without CONSULT

- Perform IPDM E/R auto active test and check cooling fan motors operation, refer to PCS-11, "Diagnosis Description".

- Check that cooling fans-1 and -2 operate at each speed (Low/Middle/High).

2.CHECK COOLING SYSTEM FOR LEAKAGE-I

Check cooling system for leakage

3.CHECK COOLING SYSTEM FOR LEAKAGE-II

Check the following for leakage.

- Hose

- Radiator

- Water pump

4.CHECK RADIATOR CAP

Check radiator cap

5.CHECK THERMOSTAT

Check thermostat.

6.CHECK ENGINE COOLANT TEMPERATURE SENSOR

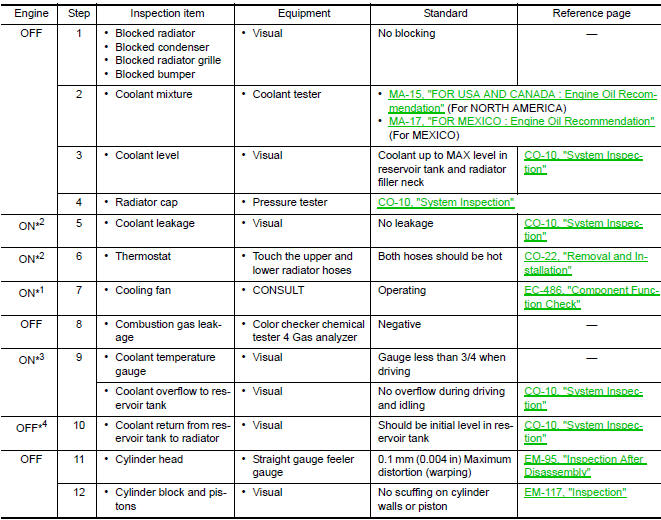

7.CHECK MAIN 12 CAUSES

If the cause cannot be isolated, check the following.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes

*3: Drive at 90 km/h (56 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time

P1212 TCS communication line

P1212 TCS communication line

Description

This CAN communication line is used to control the smooth engine operation

during the TCS operation. Pulse

signals are exchanged between ECM and "ABS actuator and electric unit (contr ...

P1225 TP sensor

P1225 TP sensor

Description

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The ...

Other materials:

Change intervals

The oil and oil filter change intervals for your

engine are based on the use of the specified

quality oils and filters. Using engine oil and filters

that are not of the specified quality, or exceeding

recommended oil and filter change intervals

could reduce engine life. Damage to the engine

ca ...

Glove box

Open the glove box by pulling the handle. Use the

master key when locking or unlocking the glove

box.

There is a trunk cancel switch in the glove box.

For additional information, refer to "Cancel

switch" in the "Pre-driving checks and adjustments"

section of this manual.

WARNING

Keep g ...

System Description

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting - Engine Noise

Camshaft bearing noise

Piston pin noise

Piston slap noise

Main bearing noise

Connecting rod bearing noise

Drive belt noise (Sticking/Slipping)

Drive belt noise (Slipping)

Water pump n ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0065