Nissan Maxima Service and Repair Manual: P1551, P1552 battery current sensor

Description

The power generation voltage variable control enables fuel consumption to be decreased by reducing the engine load which is caused by the power generation of the generator. The battery current sensor is installed to the battery cable at the negative terminal. The sensor measures the charging/discharging current of the battery.

Based on the sensor signal, ECM judges whether or not the power generation voltage variable control is performed. When performing the power generation voltage variable control, ECM calculates the target power generation voltage based on the sensor signal. And ECM sends the calculated value as the power generation command value to IPDM E/R. For the details of the power generation voltage variable control, refer to CHG-8, "System Description".

CAUTION: Never connect the electrical component or the ground wire directly to the battery terminal. The connection causes the malfunction of the power generation voltage variable control, and then the battery discharge may occur.

DTC Logic

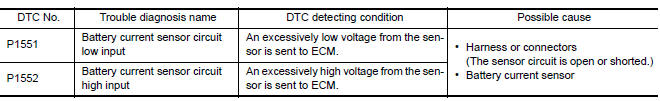

DTC DETECTION LOGIC

NOTE: If DTC P1551 or P1552 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-394, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 8 V with ignition switch ON

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 10 seconds.

- Check 1st trip DTC.

Diagnosis Procedure

1.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9.

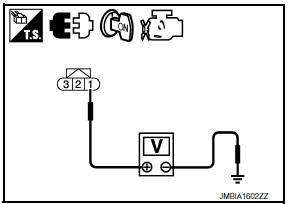

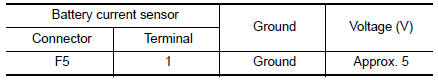

2.CHECK BATTERY CURRENT SENSOR POWER SUPPLY CIRCUIT

- Disconnect battery current sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between battery current sensor harness connector and ground.

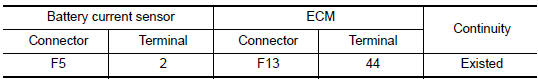

3.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

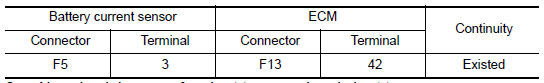

- Check the continuity between battery current sensor harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

4.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Check the continuity between battery current sensor harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

5.CHECK BATTERY CURRENT SENSOR

6.CHECK INTERMITTENT INCIDENT

Component Inspection

1.CHECK BATTERY CURRENT SENSOR

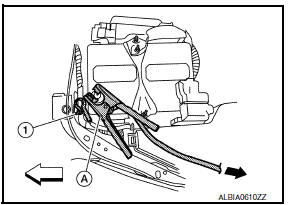

- Turn ignition switch OFF.

- Reconnect harness connectors disconnected.

- Disconnect battery negative cable (1).

: Vehicle front

: Vehicle front

: To body ground

: To body ground

- Install jumper cable (A) between battery negative terminal and body ground.

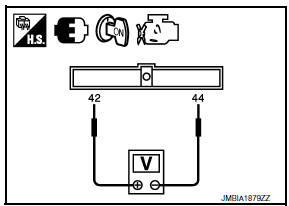

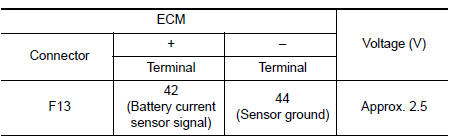

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals under the following conditions.

Before measuring the terminal voltage, confirm that the battery is fully charged.

Refer to PG-2, "How to Handle Battery".

P1550 battery current sensor

P1550 battery current sensor

Description

The power generation voltage variable control enables fuel consumption to be

decreased by reducing the

engine load which is caused by the power generation of the generator. The

batt ...

P1553 battery current sensor

P1553 battery current sensor

Description

The power generation voltage variable control enables fuel consumption to be

decreased by reducing the

engine load which is caused by the power generation of the generator. The

batt ...

Other materials:

Tweeter

Description

The audio unit sends audio signals to the tweeters using the front door

speaker circuits.

Diagnosis Procedure

1.CONNECTOR CHECK

Check the audio unit and speaker connectors for the following:

Proper connection

Damage

Disconnected or loose terminals

2.HARNESS CHECK

...

Indicator lights

For additional information, refer to "Vehicle information

display" in this section.

Front fog light indicator

light

(green)

The front fog light indicator light illuminates when

the front fog lights are on. For additional information,

refer to "Fog light switch" in this section.

Front passen ...

Clearing the programmed information

The following procedure clears the programmed

information from both buttons. Individual buttons

cannot be cleared. However, individual buttons

can be reprogrammed. For additional information,

refer to "Reprogramming a single

HomeLink button" in this section.

To clear all programming:

1. Press ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0065