Nissan Maxima Service and Repair Manual: Positive crankcase ventilation

Description

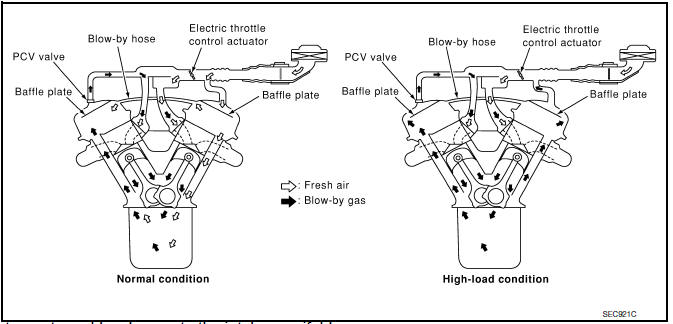

This system returns blow-by gas to the intake manifold.

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake manifold.

During partial throttle operation of the engine, the intake manifold sucks the blow-by gas via the PCV valve.

Normally, the capacity of the valve is sufficient to handle any blow-by and a small amount of ventilating air.

The ventilating air is drawn from the air inlet tubes into the crankcase. In this process the air passes via the hose connecting air inlet tubes to rocker cover.

Under full-throttle condition, the manifold vacuum is insufficient to draw the blow-by flow via the valve.

The flow goes via the hose connection in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not meet the requirement. This is because some of the flow will go via the hose connection to the air inlet tubes under all conditions.

Component Inspection

1.CHECK PCV VALVE

With engine running at idle, remove PCV valve from rocker cover. A properly working valve makes a hissing noise as air passes via the it.

A strong vacuum should be felt immediately when a finger is placed over valve inlet.

On board refueling vapor recovery (ORVR)

On board refueling vapor recovery (ORVR)

Description

From the beginning of refueling, the air and vapor inside the fuel tank go

via the refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by ...

Refrigerant pressure sensor

Refrigerant pressure sensor

Description

The refrigerant pressure sensor is installed at the condenser of the air

conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressur ...

Other materials:

U1300 AV comm circuit

Description

U1300 is indicated when a communication signal malfunction occurs. U1300 is

indicated along with DTCs that

identify components connected to the AV control unit through communication

lines. Determine the possible

malfunction cause from the table below.

SELF-DIAGNOSIS RESULTS DIS ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and

"SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT

PRE-TENSIONER", used along with a front seat belt, helps to reduce the risk

or severity of injury to the driver and front passenger for ...

B210C starter control relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B210C is displayed with DTC

U1000, first perform the trouble diagnosis for DTC U1000. Refer to

SEC-29, "DTC Logic".

If DTC B210C is displayed with DTC

U1010, first perform the trouble diagnosis for DTC U1010. Refer to

SEC-30, "D ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.011