Nissan Maxima Service and Repair Manual: Hydraulic control system

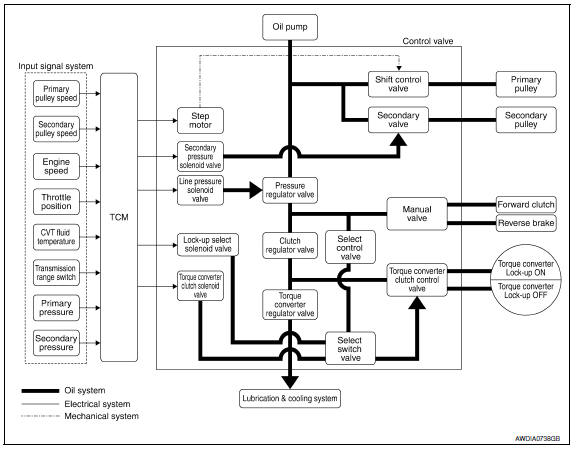

System Diagram

System Description

The hydraulic control mechanism consists of the oil pump directly driven by the engine, the hydraulic control valve that controls line pressure and transmission, and the input signal lin

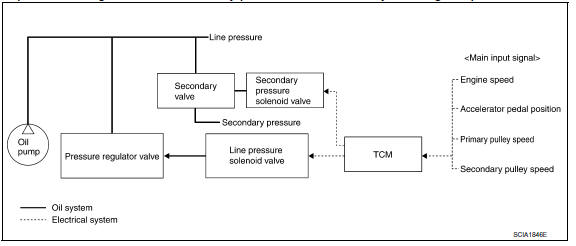

LINE PRESSURE AND SECONDARY PRESSURE CONTROL

- When an input torque signal equivalent to the engine driving force is transmitted from the ECM to the TCM, the TCM controls the line pressure solenoid valve and secondary pressure solenoid valve.

- Line pressure solenoid valve activates pressure regulator valve, and line pressure from oil pump is adjusted for the optimum driving condition. Secondary pressure is controlled by lowering line pressure.

Normal Control

Optimize the line pressure and secondary pressure, depending on driving conditions, on the basis of the throttle position, the engine speed, the primary pulley (input) revolution speed, the secondary pulley (output) revolution speed, the brake signal, the transmission range switch signal, the lock-up signal, the voltage, the target gear ratio, the fluid temperature, and the fluid pressure.

Feedback Control

For the normal fluid control and the select fluid control, secondary pressure is detected for feedback control by using a secondary pressure sensor to set a high-precision secondary pressure.

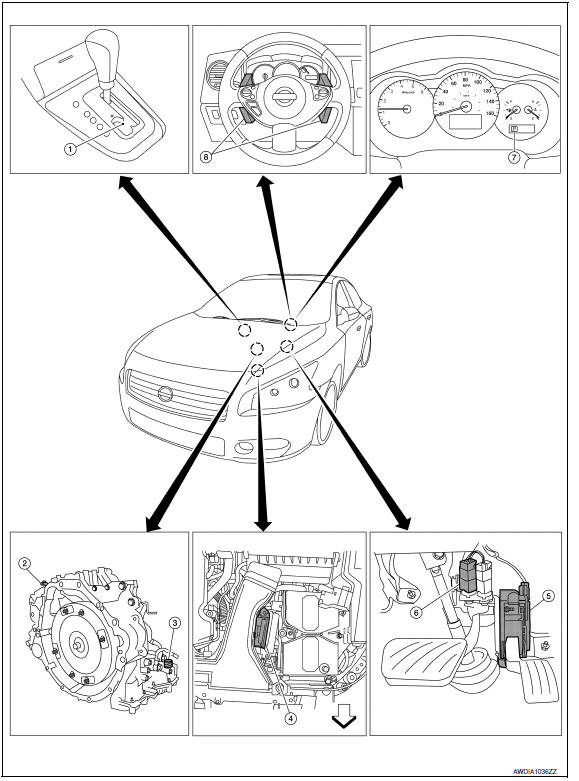

Component Parts Location

- CVT shift selector assembly (Manual mode select switch and manual mode position select switch)

- Secondary speed sensor

- CVT unit harness connector

- TCM

- Accelerator pedal position (APP) sensor

- Stop lamp switch

- Shift positioner indicator Manual mode indicator DS mode indicator

- Paddle shifters

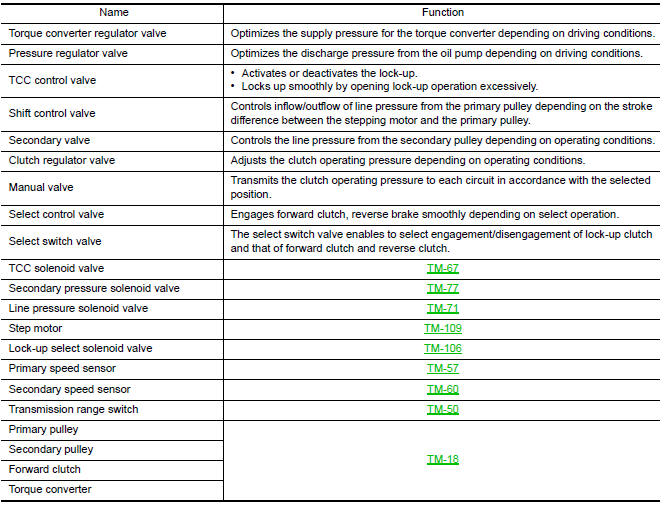

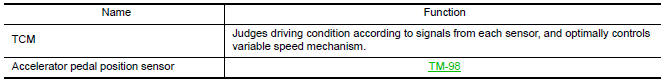

Component Description

TRANSAXLE ASSEMBLY

EXCEPT TRANSAXLE ASSEMBLY

Mechanical system

Mechanical system

Cross-Sectional View

Converter housing

Oil pump

Forward clutch

Reverse brake

Planetary carrier

Primary pulley

Steel belt

Sun ge ...

Control system

Control system

System Diagram

System Description

The CVT senses vehicle operating conditions through various sensors. It

always controls the optimum shift

position and reduces shifting and lock-up shocks.

T ...

Other materials:

P1226 TP sensor

Description

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometer which transfor ...

Interior trunk access

The trunk can be accessed from the passenger

side of the rear seat.

The rear seat can be locked using the mechanical

key to prevent unauthorized access. For additional

information, refer to "Keys" in this section.

1. Move the front passenger seat to the most

forward position.

2. Open th ...

Rear stabilizer

Removal and Installation

Removal

Remove each rear stabilizer connecting rod nut using power tools.

Disconnect the rear stabilizer from each rear stabilizer

connecting rod.

Remove each rear stabilizer clamp bolt using power tools.

Remove the rear stabilizer.

If necessary, remove each ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0072