Nissan Maxima Service and Repair Manual: Shift control system

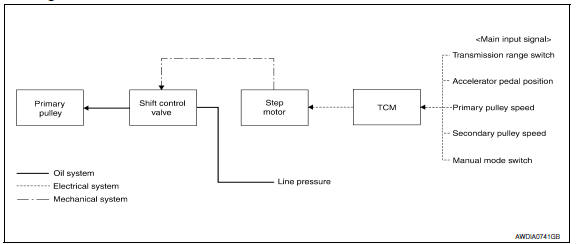

System Diagram

NOTE: The gear ratio is set for each position separately.

System Description

In order to select the gear ratio that can obtain the driving force in accordance with driver's intention and the vehicle condition, TCM monitors the driving conditions, such as the vehicle speed and the throttle position, selects the optimum gear ratio, and determines the gear change steps to the gear ratio. Then TCM sends the command to the step motor, controls the inflow/outflow of line pressure from the primary pulley to determine the position of the moving-pulley and controls the gear ratio.

"D" POSITION

Shifting over all the ranges of gear ratios from the lowest to the highest.

"M" POSITION

By moving the selector lever to + side or - side, the manual mode switch is changed over, and shift change like M/T becomes possible following the changing gear set line step by step.

"DS" POSITION

- When the selector lever is put in the manual shift gate side, the driver can drive more sporty than "D" position.

- "DS" mode can be switched according to the following method.

- When the selector lever is in the "D" position, shifting the selector lever to manual shift gate enables switching to "DS" mode.

- When in "DS" mode, shifting the selector lever to the main gate enables to cancel "DS" mode.

- After switching to manual mode with paddle shifter, switching to "DS" mode can not be enabled even when the selector lever is shifted to the manual gate. (With paddle shifter)

DOWNHILL ENGINE BRAKE CONTROL (AUTO ENGINE BRAKE CONTROL)

When a downhill slope is detected with the accelerator pedal released, the engine brake will be strengthened up by downshifting so as not to accelerate the vehicle more than necessary.

ACCELERATION CONTROL

According to vehicle speed and a change of accelerator pedal angle, driver's request for acceleration and driving scene are judged. This function assists improvement in the acceleration feeling by making the engine speed proportionate to the vehicle speed. And a shift map that can gain a larger driving force is available for compatibility of mileage with driveability.

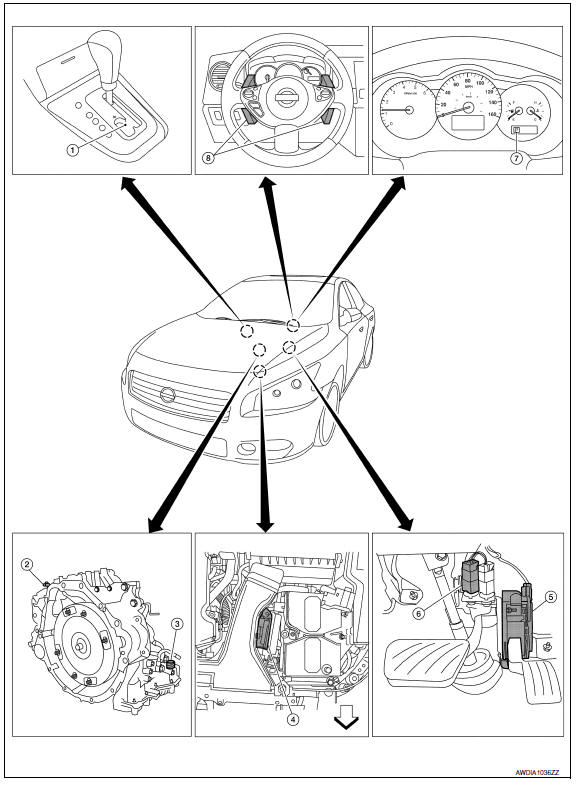

Component Parts Location

- CVT shift selector assembly (Manual mode select switch and manual mode position select switch)

- Secondary speed sensor

- CVT unit harness connector

- TCM

- Accelerator pedal position (APP) sensor

- Stop lamp switch

- Shift positioner indicator Manual mode indicator DS mode indicator

- Paddle shifters

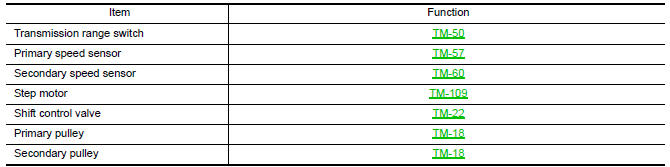

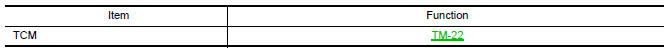

Component Description

TRANSAXLE ASSEMBLY

EXCEPT TRANSAXLE ASSEMBLY

Lock-up and select control system

Lock-up and select control system

System Diagram

System Description

The torque converter clutch piston in the torque converter is

engaged to eliminate torque converter slip to

increase power transmission efficiency. ...

Shift lock system

Shift lock system

System Diagram

System Description

The selector lever cannot be shifted from "P" position to any other position

unless the ignition switch is in the

ON position and the brake pedal is depressed ...

Other materials:

Additional service when replacing transaxle assembly

Description

When replacing the transaxle assembly, perform the following work.

ERASING, LOADING AND STORING OF CALIBRATION DATA

The TCM acquires calibration data (individual characteristic

value) of each solenoid that is stored in the

ROM assembly (in the control valve). This enabl ...

ABS branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ABS actuator and

electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

...

Around View Monitor (if so equipped)

1. CAMERA button

WARNING

Failure to follow the warnings and instructions

for the proper use of the

Around View Monitor system could

result in serious injury or death.

The Around View Monitor is a convenience

feature and is not a substitute

for proper vehicle operation because it ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0054