Nissan Maxima Service and Repair Manual: P0840 transmission fluid pressure SEN/SW A

The secondary pressure sensor detects secondary pressure of CVT and sends a signal to the TCM.

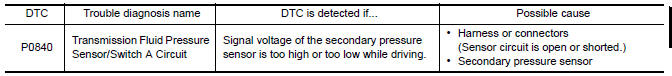

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select "Data Monitor" in "TRANSMISSION".

- Check that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN : 1.0 - 2.0 V

If it is out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage (cool down the fluid)

4. Start engine and wait for at least 5 consecutive seconds.

With GST

With GST

Follow the procedure "With CONSULT".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-126, "Wiring Diagram".

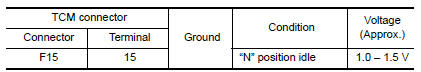

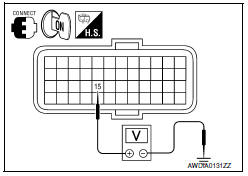

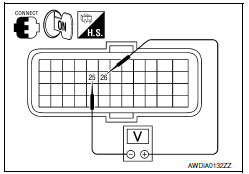

1.CHECK INPUT SIGNAL

- Start engine.

- Check voltage between TCM connector terminal and ground.

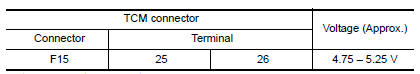

2.CHECK POWER AND SENSOR GROUND

Check voltage between TCM terminals.

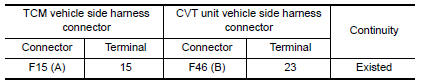

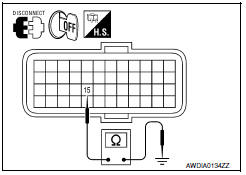

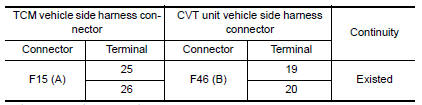

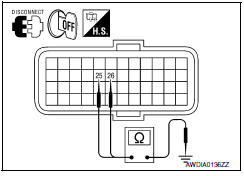

3.CHECK HARNESS BETWEEN TCM AND CVT UNIT (SECONDARY PRESSURE SENSOR) (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM vehicle side harness connector terminal and CVT unit vehicle side harness connector terminal.

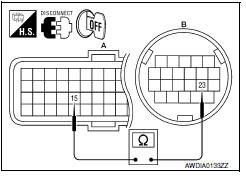

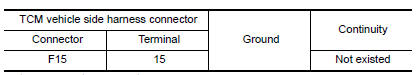

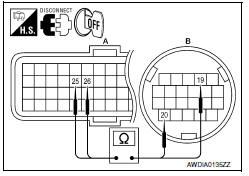

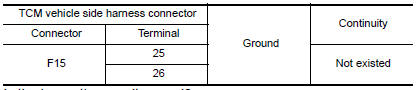

4.CHECK HARNESS BETWEEN TCM AND CVT UNIT (SECONDARY PRESSURE SENSOR) (PART 2)

Check continuity between TCM vehicle side harness connector terminal and ground.

5.CHECK HARNESS BETWEEN TCM AND CVT UNIT (SENSOR POWER AND SENSOR GROUND) (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM vehicle side harness connector terminals and CVT unit vehicle side harness connector terminals.

6.CHECK HARNESS BETWEEN TCM AND CVT UNIT (SENSOR POWER AND SENSOR GROUND) (PART 2)

Check continuity between TCM vehicle side harness connector terminals and ground.

7.CHECK TCM

- Replace with the same type of TCM. Refer to TM-168, "Exploded View".

- Connect each connector.

- Perform "DTC CONFIRMATION PROCEDURE". Refer to TM-85, "DTC Logic".

8.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

P0826 up and down shift SW

P0826 up and down shift SW

Description

Manual mode switch transmits signals (manual mode, not manual mode, shift up

and shift down) to combination

meter.

Paddle shifter transmits signals (shift up and shift down) to combi ...

P0841 transmission fluid pressure SEN/SW A

P0841 transmission fluid pressure SEN/SW A

Description

Using the engine load (throttle position), the primary pulley revolution

speed, and the secondary pulley revolution

speed as input signals, TCM changes the operating pressure of the p ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and

"SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT

PRE-TENSIONER", used along with a front seat belt, helps to reduce the risk

or severity of injury to the driver and front passenger for ...

Floor trim

Exploded View

Spacer (RH)

Spacer (LH)

Floor mat hook

Floor carpet

Harness clamp Front

Removal and Installation

REMOVAL

Disconnect the negative and positive battery terminals. Refer to

PG-68, "Removal and Installation (Battery Tray)".

Remove front seat (RH/LH). Refer t ...

Inspection and adjustment

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

Initialization of system should be conducted after the following conditions.

When the sunroof motor or sunshade motor is changed.

When the sunroof of sunshade does not operate normally ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069