Nissan Maxima Service and Repair Manual: P0826 up and down shift SW

Description

Manual mode switch transmits signals (manual mode, not manual mode, shift up and shift down) to combination meter.

Paddle shifter transmits signals (shift up and shift down) to combination meter. (With paddle shifter) Combination meter transmits signals (manual mode, not manual mode, shift up and shift down) to TCM with CAN communication signal.

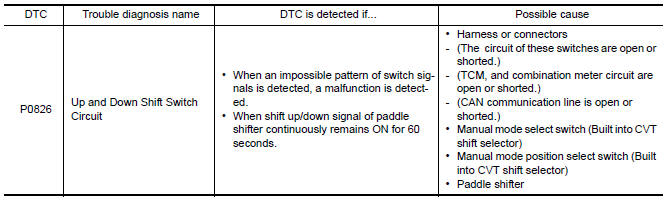

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: If "DTC CONFIRMATION PROCEDURE" has been previously performed, always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select "Data Monitor" in "TRANSMISSION".

- Drive vehicle and maintain the following conditions for at least 2 consecutive seconds.

MMODE : On

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-126, "Wiring Diagram".

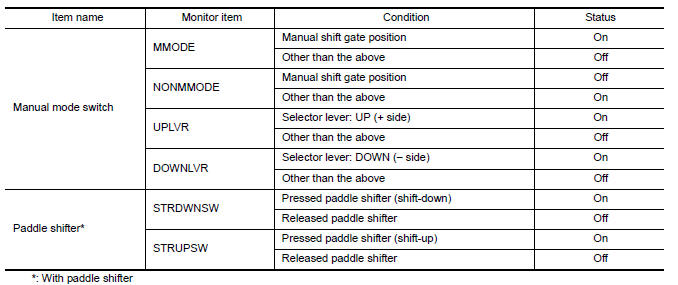

1.CHECK MANUAL MODE SWITCH SIGNALS

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select "Data Monitor" in "TRANSMISSION".

- Check the On/Off operations of each monitor item.

Without CONSULT

Without CONSULT

Drive vehicle in the manual mode, and confirm that the actual gear position and the meter's indication of the position mutually coincide when the selector lever and paddle shifter* are shifted to the "+ (up)" or "− (down)" side (1st ⇔ 6th gear).

*: With paddle shifter

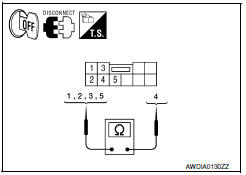

2.CHECK MANUAL MODE SWITCH

- Turn ignition switch OFF.

- Disconnect CVT shift selector connector.

- Check manual mode switch. Refer to TM-83, "Component Inspection (Manual Mode Switch)".

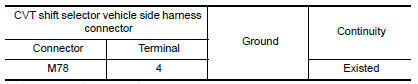

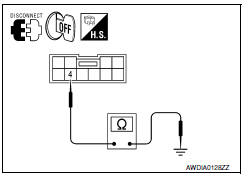

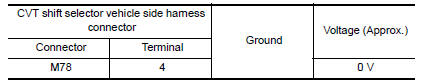

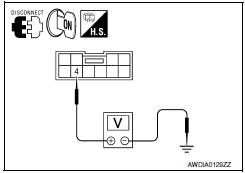

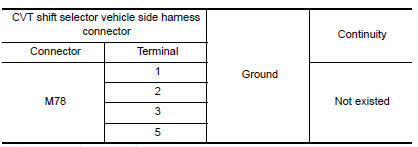

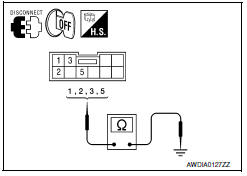

3.CHECK GROUND CIRCUIT (PART 1)

Check continuity between CVT shift selector vehicle side harness connector terminal and ground.

4.CHECK GROUND CIRCUIT (PART 2)

Check voltage between CVT shift selector vehicle side harness connector terminal and ground.

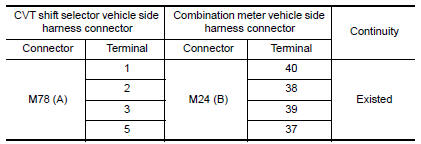

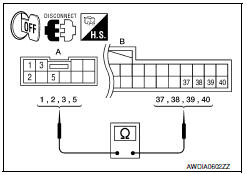

5.CHECK HARNESS BETWEEN CVT SHIFT SELECTOR AND COMBINATION METER (PART 1)

- Disconnect combination meter connector.

- Check continuity between CVT shift selector vehicle side harness connector terminals and combination meter vehicle side harness connector terminals.

6.CHECK HARNESS BETWEEN CVT SHIFT SELECTOR AND COMBINATION METER (PART 2)

Check continuity between CVT shift selector vehicle side harness connector terminals and ground.

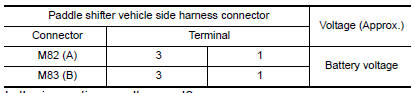

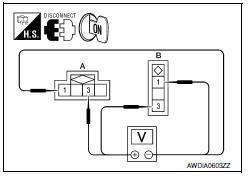

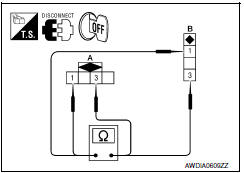

7.CHECK PADDLE SHIFTER

- Turn ignition switch OFF.

- Disconnect paddle shifter connector.

- Turn ignition switch ON.

- Check voltage between paddle shifter side harness connector terminals.

8.CHECK PADDLE SHIFTER

Check paddle shifter. Refer to TM-84, "Component Inspection (Paddle Shifter)".

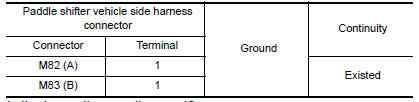

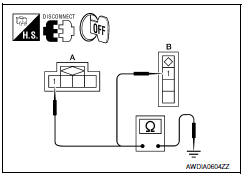

9.CHECK GROUND CIRCUIT

Check continuity between paddle shifter vehicle side harness connector terminal and ground.

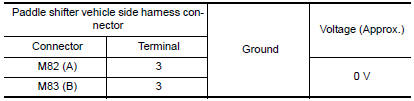

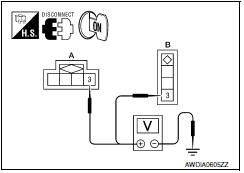

10.CHECK POWER SOURCE CIRCUIT

Check voltage between paddle shifter vehicle side harness connector terminal and ground.

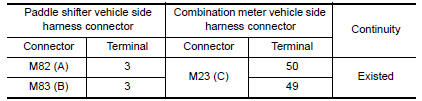

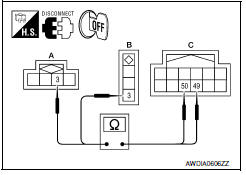

11.CHECK HARNESS BETWEEN PADDLE SHIFTER AND COMBINATION METER (PART 1)

- Disconnect combination meter connector.

- Check continuity between paddle shifter vehicle side harness connector terminals and combination meter vehicle side harness connector terminals.

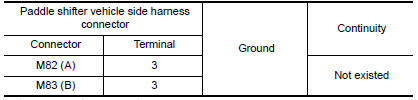

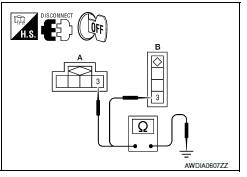

12.CHECK HARNESS BETWEEN PADDLE SHIFTER AND COMBINATION METER (PART 2)

Check continuity between paddle shifter vehicle side harness connector terminals and ground.

13.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

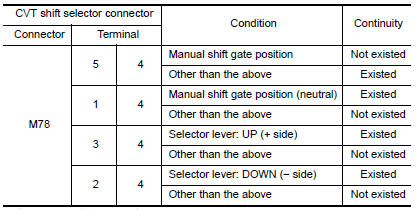

Component Inspection (Manual Mode Switch)

1.CHECK MANUAL MODE SWITCH

Check continuity between CVT shift selector connector terminals.

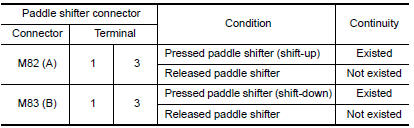

Component Inspection (Paddle Shifter)

1.CHECK PADDLE SHIFTER

Check continuity between paddle shifter connector terminals.

P0778 pressure control solenoid B

P0778 pressure control solenoid B

Description

The secondary pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition

in response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGI ...

P0840 transmission fluid pressure SEN/SW A

P0840 transmission fluid pressure SEN/SW A

The secondary pressure sensor detects secondary pressure of CVT and sends a

signal to the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

Immediately after performing any ...

Other materials:

Subwoofer

Description

The AV control unit sends audio signals to the BOSE speaker amp. The BOSE

speaker amp. amplifies the

audio signals before sending them to the subwoofers using the audio signal

circuits.

Diagnosis Procedure

1.CONNECTOR CHECK

Check the AV control unit, BOSE speaker amp. and subwo ...

Combination switch input circuit

Diagnosis Procedure

1. CHECK INPUT 1 - 5 SYSTEM CIRCUIT FOR OPEN

Turn the ignition switch OFF.

Disconnect the BCM and combination switch.

Check continuity between BCM harness connector and combination

switch harness connector.

2. CHECK INPUT 1 - 5 SYSTEM CIRCUIT FOR SHORT

...

B1XXX air bag diagnosis sensor unit

Description

DTC B1XXX AIR BAG DIAGNOSIS SENSOR UNIT

The air bag diagnosis sensor unit will run self diagnostics when the ignition

switch is turned ON. It has thepotential to set many diagnostic trouble

codes which will conform to the B1XXX format, but will not match anyother

SRS diagnostic t ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0065