Nissan Maxima Service and Repair Manual: Brake tube and hose

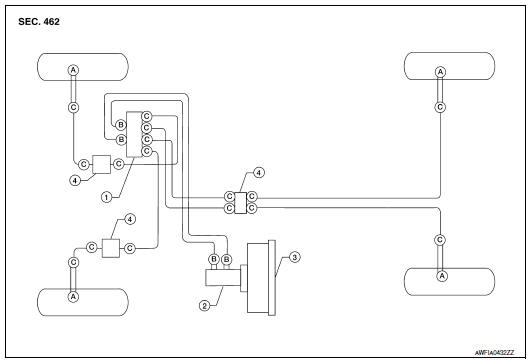

Hydraulic Circuit

- Actuator

- Master cylinder

- Brake booster

- Connector

- Union bolt 18.2 N*m (1.9 kg-m, 13 ft-lb)

- Flare nut M12 22.1 N*m (2.3 kg-m, 16 ft-lb)

- Flare nut M10 16.2 N*m (1.7 kg-m, 12 ft-lb)

CAUTION:

- All hoses and piping (tubes) must be free from excessive bending, twisting and pulling.

- Make sure there is no interference with other parts when turning the steering wheel both clockwise and counterclockwise.

- The brake piping is an important safety part. If a brake fluid leak is detected, always disassemble the parts. Replace applicable part with a new one, if necessary.

- Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed on painted areas, wash it away with water immediately.

- Do not bend or twist brake hose sharply, or strongly pull it.

- When removing components, cover connections so that no dirt, dust, or other foreign matter gets in.

- Refill with new specified brake fluid. Refer to MA-15, "FOR USA

AND CANADA : Fluids and Lubricants"

(for United States and Canada) or MA-16, "FOR MEXICO : Fluids and

Lubricants" (for Mexico).

- Do not reuse drained brake fluid.

FRONT BRAKE

FRONT BRAKE : Inspection

INSPECTION AFTER REMOVAL

CAUTION: Brake tubes and hoses are important safety parts. Always disassemble the parts and retighten their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part is detected.

- Check brake lines (tubes and hoses) and connections for fluid leaks, damage, twists, deformation, contacts with other parts, and loose connections. Replace any parts as necessary. Refer to BR-20, "Removal and Installation of Front Brake Piping and Brake Hose".

- While depressing brake pedal under a force of 785 N (80 kg, 177 lb) with engine running for approximately 5 seconds, check each part for fluid leaks.

REAR BRAKE

REAR BRAKE : Inspection

INSPECTION AFTER REMOVAL

CAUTION: Brake tubes and hoses are important safety parts. Always disassemble the parts and retighten their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part is detected.

- Check brake lines (tubes and hoses) and connections for fluid leaks, damage, twists, deformation, contacts with other parts, and loose connections. Replace any parts as necessary. Refer to BR-21, "Removal and Installation of Rear Brake Piping and Brake Hose".

- While depressing brake pedal under a force of 785 N (80 kg, 177 lb) with engine running for approximately 5 seconds, check each part for fluid leaks.

Vacuum lines

Vacuum lines

Inspection

VISUAL INSPECTION

Check for improper assembly, damage and deterioration. Replace as necessary.

CHECK VALVE INSPECTION

Airtightness Inspection

Use a suitable tool to check the built ...

Other materials:

Hood

HOOD ASSEMBLY

HOOD ASSEMBLY : Exploded View

Hood hinge cover (LH)

Hood stay (LH)

Hood hinge (LH)

Hood assembly

Hood bumper rubber

Seal

Hood insulator

Hood insulator clips

HOOD ASSEMBLY : Removal and Installation

CAUTION:

Use two people when removing or installi ...

Headlamp aiming adjustment

Description

PREPARATION BEFORE ADJUSTING

CAUTION: Do not use organic solvent

(thinner, gasoline etc.)

NOTE:

For details, refer to the regulations in your own country.

Perform aiming adjustment if the vehicle front body has been

repaired and/or the front combination lamp assembly has be ...

C1115 ABS sensor [abnormal signal]

Description

When the sensor rotor rotates, the magnetic field changes. It converts the

magnetic field changes to current

signals (rectangular wave) and transmits them to the ABS actuator and electric

unit (control unit).

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0106