Nissan Maxima Service and Repair Manual: Diagnosis and repair workflow

Work Flow

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steering system parts, suspension system parts, ABS actuator and electric unit (control unit) or if wheel alignment has been adjusted, be sure to adjust neutral position of steering angle sensor before driving. Refer to BRC-6, "ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Description".

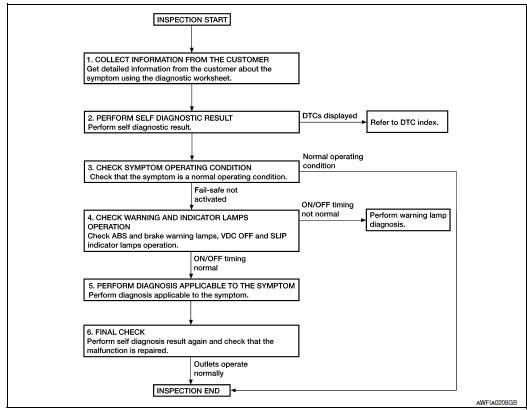

OVERALL SEQUENCE

1.COLLECT INFORMATION FROM THE CUSTOMER

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred) using the diagnosis worksheet.

2.PERFORM SELF DIAGNOSTIC RESULT

Perform self diagnostic result

3.CHECK SYMPTOM OPERATING CONDITION

Check that the symptom is a normal operating condition

4.CHECK WARNING AND INDICATOR LAMPS OPERATION

Check warning and indicator lamps operation.

- ABS warning lamp:

- Brake warning lamp:

- VDC OFF indicator lamp

- SLIP indicator lamp:

5.PERFORM DIAGNOSIS APPLICABLE TO THE SYMPTOM

Perform diagnosis applicable to the symptom.

6.FINAL CHECK

Perform self diagnostic result again, and check that the malfunction is repaired. After checking, erase the self diagnosis memory

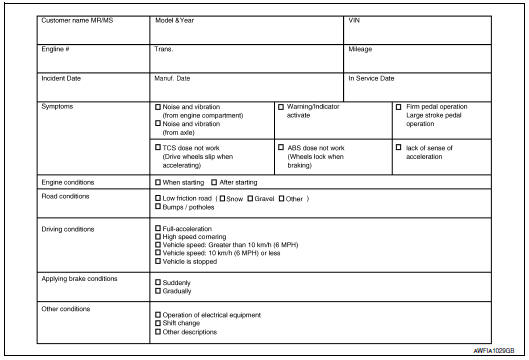

Diagnostic Work Sheet

Basic inspection

Basic inspection

...

Inspection and adjustment

Inspection and adjustment

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

After replacing the ABS actuator and electric unit (control unit), perform

the neutral p ...

Other materials:

Tire dressings

NISSAN does not recommend the use of tire

dressings. Tire manufacturers apply a coating to

the tires to help reduce discoloration of the rubber.

If a tire dressing is applied to the tires, it may

react with the coating and form a compound. This

compound may come off the tire while driving and ...

Center speaker

Description

The audio unit sends audio signals to the BOSE speaker amp. The BOSE speaker

amp. amplifies the audio signals before sending them to the center speaker

using the audio signal circuits.

Diagnosis Procedure

1.CONNECTOR CHECK

Check the audio unit, BOSE speaker amp. and speaker conne ...

Exterior lighting system symptoms

Symptom Table

CAUTION: Perform the self-diagnosis with CONSULT

before the symptom diagnosis. Perform the trouble diagnosis if any DTC is

detected.

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0109