Nissan Maxima Service and Repair Manual: C1101, C1102, C1103, C1104 wheel sensor

DTC Logic

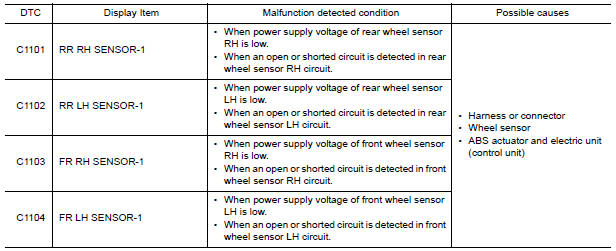

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

- Start engine and drive vehicle at approximately 21 km/h (13 MPH) or more for approximately 5 minutes.

- Perform self diagnostic result.

Diagnosis Procedure

CAUTION: Do not check between wheel sensor terminals.

1.CONFIRM DTC

With CONSULT

- Perform self-diagnostic result of ABS and record all active DTCs.

- Clear all DTCs.

- Perform DTC confirmation procedure.

2.INSPECT WHEEL SENSOR

Inspect the suspect wheel sensor for damage or deformation.

3.HARNESS AND CONNECTOR INSPECTION

- Disconnect ABS actuator and electric unit (control unit) connector E26 and wheel sensor connector of suspect wheel.

- Check harness, connectors and terminals for corrosion, deformation, disconnection, looseness or damage.

4.CHECK WHEEL SENSOR OUTPUT SIGNAL

- Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

- Turn on the ABS active wheel sensor tester power switch. NOTE: The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the battery in the ABS active wheel sensor tester before proceeding.

- Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal. NOTE: If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and retest.

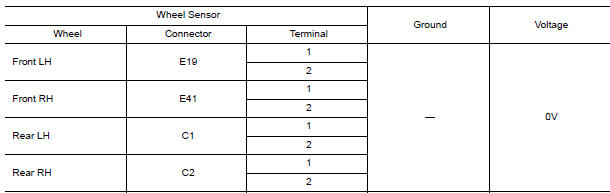

5.CHECK WIRING HARNESS FOR SHORT TO VOLTAGE

- Turn ignition switch ON.

- Check voltage between wheel sensor harness connector terminals of suspect wheel and ground.

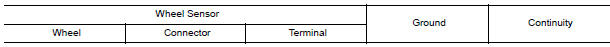

6.CHECK WIRING HARNESS FOR SHORT TO GROUND

- Turn ignition switch OFF.

- Check continuity between wheel sensor harness connector terminals of suspect wheel and ground.

7.CHECK WIRING HARNESS FOR SHORT BETWEEN CIRCUITS

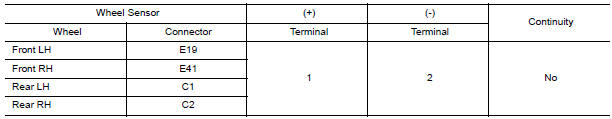

Check continuity between wheel sensor harness connector terminals of suspect wheel.

8.CHECK WIRING HARNESS FOR OPEN CIRCUIT

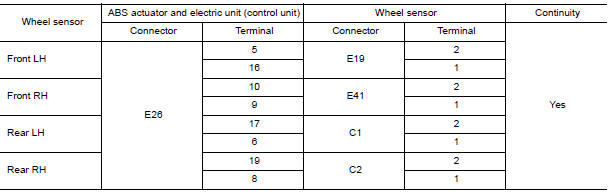

Check continuity between ABS actuator and electric unit (control unit) connector E26 and wheel sensor connector of wheel with DTC.

9.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY CIRCUIT

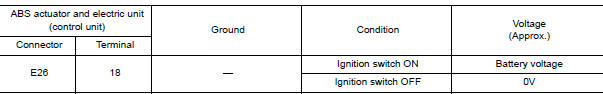

- Turn ignition switch ON.

- Check voltage between ABS actuator and electric unit (control unit) harness connector E26 terminal and ground.

10.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

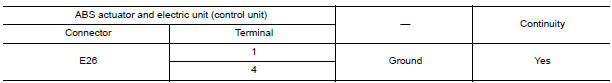

- Turn ignition switch OFF.

- Check continuity between ABS actuator and electric unit (control unit) connector E26 terminals and ground.

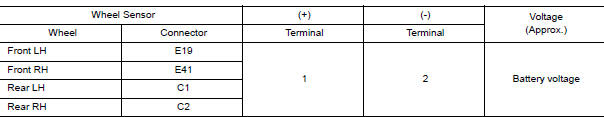

11.CHECK WHEEL SENSOR INPUT VOLTAGE

- Connect ABS actuator and electric unit (control unit) connector E26.

- Turn ignition switch ON.

- Check voltage between suspect wheel sensor harness connector terminals.

12.CONFIRM REPAIR

With CONSULT

- Clear all DTCs.

- Perform DTC confirmation procedure.

C1105, C1106, C1107, C1108 wheel sensor

C1105, C1106, C1107, C1108 wheel sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

Start engine and drive vehicle at approximately 21 km/h (13 MPH)

or more for approx ...

Other materials:

Front door speaker

Removal and Installation

REMOVAL

Remove the front door finisher. Refer to INT-18, "Removal and

Installation".

Remove the front door speaker screws (A).

Disconnect the harness connector from the front door speaker

(1) and remove.

Remove the front door speaker spacer screws (B) and ...

Periodic maintenance

ROAD WHEEL

Inspection

ALUMINUM WHEEL

Check tires for wear and improper inflation.

Check wheels for deformation, cracks and other damage. If deformed,

remove wheel and check wheel runout.

Remove tire from aluminum wheel and

mount on a tire balance machine. Refer to WT-62, "Rem ...

ECU diagnosis information

A/C AUTO AMP.

Reference Value

VALUES ON THE DIAGNOSIS TOOL

CONSULT MONITOR ITEM

A/C AUTO AMP. HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR A/C AUTO AMP.

DTC Inspection Priority Chart

If some DTCs are displayed at the same time, perform inspections one b ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0061