Nissan Maxima Service and Repair Manual: Steering wheel

Inspection

INSTALLATION CONDITION

- Check installation conditions of steering gear assembly, front suspension assembly, axle and steering column assembly.

- Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial direction.

- Check steering gear assembly bolts and nut for looseness.

STEERING WHEEL PLAY

- Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the outer circumference.

- When the measurement value is outside the standard value, check backlash for each joint of steering column assembly and installation condition of steering gear assembly.

NEUTRAL POSITION OF STEERING WHEEL

- Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the correct position.

- Perform neutral position inspection after wheel alignment. Refer to FSU-6, "Inspection and Adjustment".

- Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

- Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steering wheel is not in the neutral position.

STEERING WHEEL TURNING FORCE

- Park vehicle on a level, dry surface and set parking brake.

- Start engine.

- Bring power steering fluid up to adequate operating temperature.

Make sure the fluid temperature is approximately 50 - 80C (122 - 176F).

Tires need to be inflated to normal pressure.

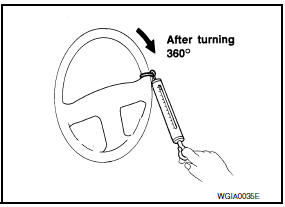

- Check steering wheel turning force using Tool when steering wheel has been turned 360 degrees from the neutral position.

- If steering wheel turning force is out of specification, check rack sliding force.

Tool number : - (J-44372)

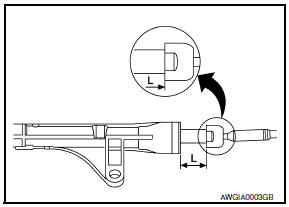

- While pulling outer socket slowly in +-11.5 mm (+-0.453 in) range from neutral position, make sure rack sliding force is within specification using Tool.

- If rack sliding force is not within specification, replace steering gear assembly.

Tool number : - (J-44372)

- If rack sliding force is OK, inspect steering column.

FRONT WHEEL TURNING ANGLE

- Check front wheel turning angle after toe-in inspection. Place

front wheels on turning radius gauges and rear wheels on stands.

Check the maximum inner and outer wheel turning angles for LH and RH road wheels.

- With the engine at idle, turn steering wheel from full left stop to full right stop and measure the turning angles.

- Measure rack stroke in neutral position if angles are outside the specified value.

Power steering fluid

Power steering fluid

Inspection

FLUID LEVEL

Check fluid level with engine stopped.

Make sure that fluid level is between MIN and MAX.

Fluid levels at HOT (A) and COLD (B) are different. Do not confuse

them.

...

Power steering oil pump

Power steering oil pump

Inspection

CAUTION: Make sure that belt tension is

normal before starting the following procedure.

Connect the Tool between oil pump discharge connector and

high-pressure hose. Bleed air fro ...

Other materials:

Parking brake switch signal circuit

Description

Transmits the parking brake switch signal to the

combination meter.

Component Function Check

1.COMBINATION METER INPUT SIGNAL

Select "METER/M&A" on CONSULT.

Monitor "PKB SW" of "DATA MONITOR" while

applying and releasing the parking brake.

> ...

Auto light system

System Diagram

System Description

BCM (Body Control Module) controls auto light operation according to

signals from optical sensor, lighting switch and ignition switch.

IPDM E/R (Intelligent Power Distribution Module Engine Room) operates

parking, license plate, tail, front fog lamps ...

Environmental factors influence the rate of corrosion

Moisture

Accumulation of sand, dirt and water on the vehicle

body underside can accelerate corrosion.

Wet floor coverings will not dry completely inside

the vehicle and should be removed for drying to

avoid floor panel corrosion.

Relative humidity

Corrosion will be accelerated in areas of h ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0078