Nissan Maxima Service and Repair Manual: Steering gear and linkage

Exploded View

- Outer socket

- Boot clamp

- Boot

- Inner socket

- Boot clamp

- SSPS valve (part of gear assembly)

- Gear assembly

Front

Three Bond 1111B or equivalent

Disassembly

- Remove outer socket locknut and outer socket.

- Remove boot clamps and boot. CAUTION: Do not reuse boot clamps.

- Remove inner socket.

Inspection

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for cracks. Replace if any damage is found.

Outer Socket and Inner Socket

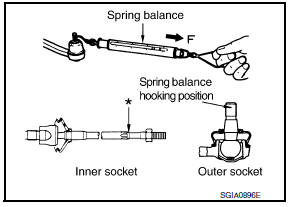

- Ball joint swinging torque

- Hook a spring balance to the ball stud and inner socket measuring point (*) and pull the spring balance. Make sure that the spring balance reads the specified value when ball stud and inner socket start to move. Replace outer socket and steering gear assembly if they are outside the standard.

Tool number : - (J-44372)

- Ball joint rotating torque

- Make sure that the reading is within the following specified range using Tool. Replace outer socket if the reading is outside the specified value.

Tool number : ST3127S000 (J-25765-A)

- Ball joint axial end play

- Apply an axial load of 490 N (50 kg, 111 lb) to ball stud. Measure amount of stud movement using a dial gauge and then make sure that the value is within the following specified range. Replace outer socket and inner socket if the measured value is outside the standard.

Assembly

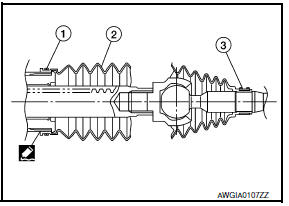

- Apply Three Bond 1111B or equivalent to inner socket and turn pinion fully to retract inner socket into gear housing assembly.

- Install large end (1) of boot (2) to gear housing assembly.

- Install small end (3) of boot (2) to inner socket boot mounting groove.

- Install boot clamp to boot small end. CAUTION: Do not reuse boot clamps.

- Install boot clamp to boot large end using Tool. CAUTION: Do not reuse boot clamps.

Tool number : KV40107300 ( - )

- Adjust inner socket to standard length (L), and then tighten lock nut to the specified torque. Check length of inner socket (L) again after tightening lock nut. Make sure that the length is the standard.

CAUTION: Adjust toe-in after this procedure. The length achieved after toe-in adjustment is not necessarily the above value.

POWER STEERING OIL PUMP

Disassembly and Assembly

The power steering oil pump and pulley is not serviceable and should be replaced as an assembly. For front and rear bracket removal

Steering column

Steering column

Disassembly and Assembly

The steering column assembly without electric motor is not serviceable and

must be replaced as an assembly.

With Electric Motor

Steering column assembly

Telesco ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Steering Wheel

Steering Angle

Steering Column

STEERING COLUMN LENGTH

STEERING COLUMN ROTATING TORQUE

TILT MECHANISM OPERATING RANGE

Steering Gear

STEERING OUTER SOCKET AND INNER ...

Other materials:

Blower motor

Description

COMPONENT DESCRIPTION

Brush-less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point of contact and the coil rotated.

Blower Motor Circuit

Component Function Check

1.CHECK OP ...

Diagnosis system (HVAC)

CONSULT Function

CONSULT can display each diagnosis item using the diagnosis test modes as

shown.

CONSULT application items

SELF DIAGNOSTIC RESULT

Display Item List

*: Perform self-diagnosis under sunshine. When performing indoors, aim a

light (more than 60 W) at sunload sensor, ...

Sunroof system

System Diagr

SUNROOF

System Description

SUNROOF SYSTEM

INPUT/OUTPUT SIGNAL CHART

SUNROOF OPERATION

Sunroof motor assembly operates with the power supply that is

output from BCM while ignition switch is ON or retained power is

operating.

Tilt up/ down & slide open/ close si ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0288