Nissan Maxima Service and Repair Manual: Side air bag (satellite) sensor

Removal and Installation

CAUTION:

- Before servicing, turn ignition switch OFF, disconnect both battery terminals and wait at least 3 minutes.

- Do not use air tools or electric tools for servicing.

- Replace the satellite sensor of deployed SRS front side air bag and deployed SRS side curtain air bag.

- Do not cause impact to the side air bag (satellite) sensor by dropping etc. Replace the side air bag (satellite) sensor if it has been dropped or sustained an impact.

REMOVAL

- Disconnect the negative and positive battery terminals, then wait at least 3 minutes. Refer to PG-67, "Removal and Installation (Battery)".

- Remove the front seat belt retractor. Refer to SB-6, "Removal and Installation".

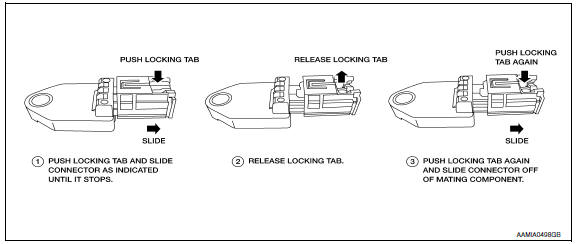

- Disconnect the harness connector from the side air bag (satellite) sensor slide double locking. Refer to SRC-9, "SRS Component Connectors".

- Remove the nuts (A), then remove side air bag (satellite) sensor (2)

from center pillar (1) studs.

: Front

: Front

(3): Side air bag (satellite) sensor slide double locking harness connector.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not use old nuts after removal; replace with new nuts.

- Be careful not to damage the satellite sensor harness.

- After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

- In case a malfunction is detected by the air bag warning lamp, reset by the self-diagnosis function and delete the memory by CONSULT.

- If a malfunction is still detected after the above operation,

perform self-diagnosis to repair malfunctions.

Refer to SRC-12, "SRS Operation Check".

Crash zone sensor

Crash zone sensor

Component

Crash zone sensor harness connector

Crash zone sensor

Nut

Front

Removal and Installation

CAUTION:

Before servicing, turn ignition switch OFF, disconnect both

bat ...

Diagnosis sensor unit

Diagnosis sensor unit

Removal and Installation

WARNING:

Before servicing, turn ignition switch OFF, disconnect both

battery terminals and wait at least 3 minutes.

Before disconnecting the air bag sensor unit harn ...

Other materials:

Emission control system warranty

Your NISSAN vehicle is covered by the following

emission warranties:

For USA

1. Emission Defects Warranty

2. Emissions Performance Warranty

Details of this warranty may be found with other

vehicle warranties in your Warranty Information

Booklet which comes with your NISSAN vehicle.

If you ...

Engine maintenance (VQ35DE)

DRIVE BELTS

DRIVE BELTS : Checking Drive Belts

Idler pulley

Drive belt

Power steering oil pump

Drive belt auto-tensioner

Crankshaft pulley

Idler pulley

A/C compressor

Generator

Indicator

New drive belt range

Possible use range

View D

Engine front

WA ...

CVT fluid

Inspection

CHECKING CVT FLUID

The fluid level should be checked with the fluid warmed

up to 50 to 80C (122 to 176F). The fluid level

check procedure is as follows:

Check for fluid leakage.

With the engine warmed up, drive the vehicle in

an urban area.

When amb ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0062