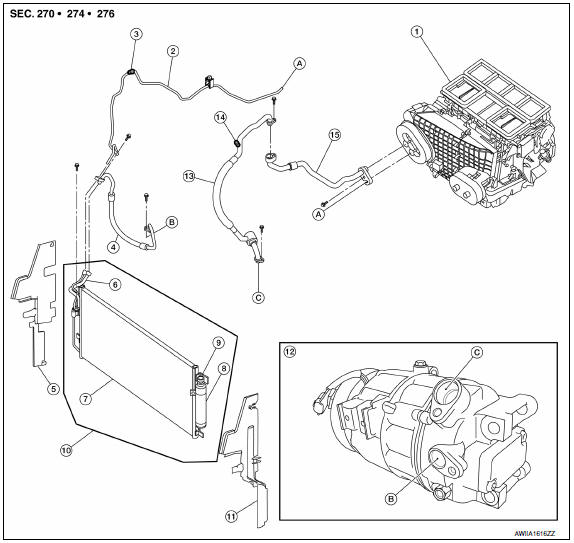

Nissan Maxima Service and Repair Manual: Cooler pipe and hose

Exploded View

- Heater and cooling unit assembly

- High-pressure pipe

- High-pressure A/C service valve

- High-pressure flexible hose

- Air deflector (RH)

- Junction pipe

- Condenser

- Liquid tank

- Refrigerant pressure sensor

- Condenser, liquid tank and refrigerant pressure sensor

- Air deflector (LH)

- Compressor

- Low-pressure flexible hose

- Low-pressure A/C service valve

- Low-pressure pipe

- High-pressure pipe to heater and cooling unit assembly

- High-pressure flexible hose to compressor

- Low-pressure flexible hose to compressor

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE : Removal and I

REMOVAL

CAUTION: Before servicing, turn the ignition switch off, disconnect both battery terminals and wait at least three minutes.

- Discharge the refrigerant.

- Partially drain the engine cooling system. Refer to CO-11, "Changing Engine Coolant".

- Disconnect the battery negative and positive terminals.

- Remove the engine room cover.

- Remove the air cleaner assembly and air ducts. Refer to EM-24, "Removal and Installation".

- Remove the upper radiator hose.

- Remove the battery and battery tray. Refer to PG-68, "Removal and Installation (Battery Tray)".

- Remove the engine cooling fan and shroud assembly. Refer to CO-17, "Removal and Installation".

- Disconnect the low-pressure flexible hose from the compressor and the low-pressure pipe. CAUTION: Cap or wrap the joint of the hose with suitable material such as vinyl tape to avoid the entry of air.

- Remove the low-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to the new O-rings for installation.

- After recharging the refrigerant, check for leaks. Refer to HA-26, "Leak Test".

LOW-PRESSURE PIPE

LOW-PRESSURE PIPE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-28, "Recycle Refrigerant".

- Remove the hoodledge covers (LH/RH).

- Remove the strut tower bar. Refer to FSU-13, "Exploded View".

- Remove the upper cowl. Refer to EXT-21, "Removal and Installation".

- Remove the lower RH cowl.

- Reposition the power steering reservoir out of the way without disconnecting the hose.

- Disconnect the power steering hose clamp to reposition the power steering hose out of the way without disconnecting the hose.

- Disconnect the low-pressure pipe from the expansion valve and the low-pressure hose.

CAUTION:

- Cap or wrap the joint of the pipe with a suitable material such as vinyl tape to avoid the entry of air.

- Remove the low-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to the new O-rings for installation.

- - After recharging the refrigerant, check for leaks. Refer to HA-26, "Leak Test".

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE : Removal and Installation

REMOVAL

CAUTION: Before servicing, turn the ignition switch off, disconnect both battery terminals and wait at least three minutes.

- Discharge the refrigerant. Refer to HA-28, "Recycle Refrigerant".

- Partially drain the engine cooling system. Refer to CO-11, "Changing Engine Coolant".

- Disconnect the battery negative and positive terminals.

- Remove the hoodledge covers (LH/RH).

- Remove the air cleaner assembly and air ducts. Refer to EM-24, "Removal and Installation".

- Remove the upper radiator hose.

- Remove the battery and battery tray. Refer to PG-68, "Removal and Installation (Battery Tray)".

- Remove the engine cooling fan and shroud assembly. Refer to CO-16, "Removal and Installation".

- Disconnect the high-pressure flexible hose from the compressor and the high-pressure pipe and junction pipe. CAUTION: Cap or wrap the joint of the hose with suitable material such as vinyl tape to avoid the entry of air.

- Remove the high-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to the new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-26, "Leak Test".

HIGH-PRESSURE PIPE

HIGH-PRESSURE PIPE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-28, "Recycle Refrigerant".

- Remove the hoodledge covers (LH/RH).

- Remove the strut tower bar. Refer to FSU-13, "Exploded View".

- Remove the upper cowl. Refer to EXT-21, "Removal and Installation".

- Remove the lower RH cowl.

- Reposition the engine coolant reservoir out of the way without disconnecting the hose.

- Reposition the power steering reservoir out of the way without disconnecting the hose.

- Disconnect the power steering hose clamp to reposition the power steering hose out of the way without disconnecting the hose.

- Remove the torque rod. Refer to EM-103, "Removal and Installation".

- Disconnect the harness bracket from the engine cover.

- Disconnect the high-pressure pipe from the expansion valve and the high-pressure flexible hose and junction pipe. CAUTION: Cap or wrap the joint of the pipe with a suitable material such as vinyl tape to avoid the entry of air.

- Remove the high-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to the new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-26, "Leak Test".

Removal and installation

Removal and installation

COMPRESSOR

Removal and Installation for Compressor

REMOVAL

CAUTION: Before servicing, turn the ignition

switch off, disconnect both battery terminals and wait at least three

minutes.

Di ...

Condenser

Condenser

CONDENSER

CONDENSER : Removal and Installation

REMOVAL

Discharge the refrigerant. Refer to HA-28, "Recycle Refrigerant".

Remove the RH hoodledge cover.

Remove the front bumper fascia. Refer ...

Other materials:

Diagnosis system (BCM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions.

WIPER

WIPER : CONSULT Function (BCM - WIPER)

DATA MONITOR

ACTIVE TEST

...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and

"SEAT BELTPRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT

PRE-TENSIONER", used alongwith a front seat belt, helps to reduce the risk

or severity of injury to the driver and front passenger for c ...

BCM (body control module)

Reference Value

NOTE: The Signal Tech II Tool (J-50190) can

be used to perform the following functions. Refer to the Signal Tech II User

Guide for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS transmitter

Read TPMS DTCs

Re ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0066