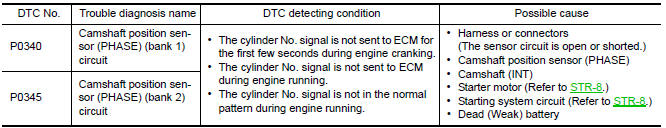

Nissan Maxima Service and Repair Manual: P0340, P0345 CMP sensor (PHASE)

Description

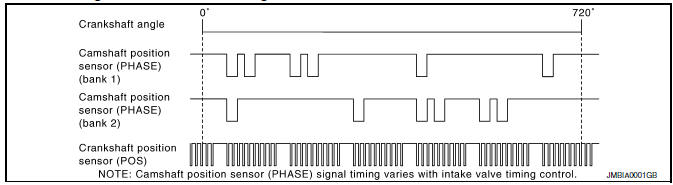

The camshaft position sensor (PHASE) senses the retraction of camshaft (INT) to identify a particular cylinder. The camshaft position sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoperative, the camshaft position sensor (PHASE) provides various controls of engine parts instead, utilizing timing of cylinder identification signals.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to change.

Due to the changing magnetic field, the voltage from the sensor changes.

ECM receives the signals as shown in the figure.

DTC Logic

DTC DETECTION LOGIC

NOTE: If DTC P0340 or P0345 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 10.5 V with ignition switch ON.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

- Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

- Check 1st trip DTC.

3.PERFORM DTC CONFIRMATION PROCEDURE-I

- Maintaining engine speed at more than 800 rpm for at least 5 seconds.

- Check 1st trip DTC.

Diagnosis Procedure

1.CHECK STARTING SYSTEM

Turn ignition switch to START position.

2.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9.

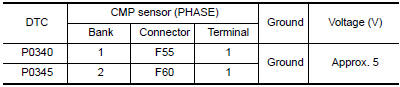

3.CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY CIRCUIT

- Disconnect camshaft position (CMP) sensor (PHASE) harness connector.

- Turn ignition switch ON.

- Check the voltage between CMP sensor (PHASE) harness connector and ground.

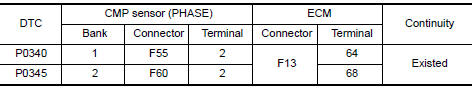

4.CHECK CMP SENSOR (PHASE) GROUND CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

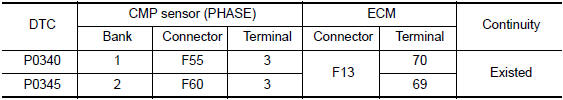

5.CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

6.CHECK CAMSHAFT POSITION SENSOR (PHASE)

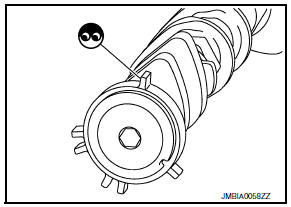

7.CHECK CAMSHAFT (INT)

Check the following.

- Accumulation of debris to the signal plate of camshaft rear end

- Chipping signal plate of camshaft rear end

8.CHECK INTERMITTENT INCIDENT

Component Inspection

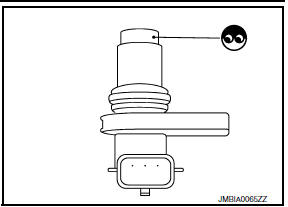

1.CHECK CAMSHAFT POSITION SENSOR (PHASE)-I

- Turn ignition switch OFF.

- Loosen the fixing bolt of the sensor.

- Disconnect camshaft position sensor (PHASE) harness connector.

- Remove the sensor.

- Visually check the sensor for chipping.

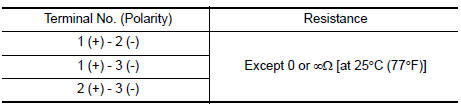

2.CHECK CAMSHAFT POSITION SENSOR (PHASE)-II

Check resistance camshaft position sensor (PHASE) terminals as per the following.

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

Description

The crankshaft position sensor (POS) is located on the oil pan facing

the gear teeth (cogs) of the signal plate. It detects the fluctuation of

the engine revolution.

The sensor ...

P0420, P0430 three way catalyst function

P0420, P0430 three way catalyst function

DTC Logic

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen st ...

Other materials:

Precaution

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR

BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and

"SEAT BELT PRE-TENSIONER", used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and fr ...

Rear power window switch

Description

BCM supplies power.

Rear power window motor operates when rear power window switch is

activated.

Component Function Check

Rear Power Window Switch

1. CHECK REAR POWER WINDOW MOTOR FUNCTION

Check that rear power window motor operates from rear power window switch.

Diagnosi ...

How to use the remote keyless entry function

The remote keyless entry function can operate all

door locks using the remote keyless function of

the Intelligent Key. The remote keyless function

can operate at a distance of 33 ft (10 m) away

from the vehicle. The operating distance depends

upon the conditions around the vehicle.

The remot ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.006