Nissan Maxima Service and Repair Manual: B257B, B257C ambient sensor

Description

COMPONENT DESCRIPTION

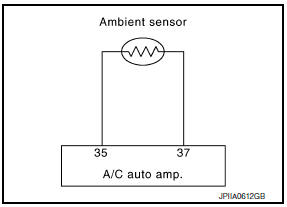

Ambient Sensor

- The ambient sensor (1) is installed to the front bumper reinforcement.

- It detects ambient temperature and converts it into a resistance value which is then input into the A/C auto amp.

Ambient Sensor Circuit

AMBIENT TEMPERATURE INPUT PROCESS

The A/C auto amp. equips a processing circuit for the ambient sensor input. However, when the temperature detected by the ambient sensor increases quickly, the processing circuit retards the A/C auto amp. function. It only allows the A/C auto amp. to recognize an ambient temperature increase of 0.33C (0.6F) per 100 seconds.

As an example, consider stopping for a few minutes after high-speed driving. Although the actual ambient temperature has not changed, the temperature detected by the ambient sensor increases. This is because the heat from the engine compartment can radiate to the front bumper area, the location of the ambient sensor.

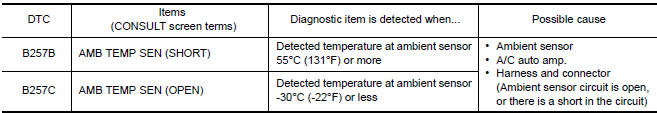

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010. Refer to HAC- 30, "DTC Logic" or HAC-31, "DTC Logic".

- If there is an open circuit in the ambient sensor, A/C auto amp. registers extreme cold [-30C (-22F)] and adjusts the temperature control warmer.

DTC CONFIRMATION PROCEDURE

1.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

- Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

- Check if any DTC No. is displayed in the self-diagnosis results.

NOTE:

- If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010. Refer to HAC- 30, "DTC Logic" or HAC-31, "DTC Logic".

- If there is an open circuit in the ambient sensor, A/C auto amp. registers extreme cold [-30C (-22F)] and adjusts the temperature control warmer.

Diagnosis Procedure

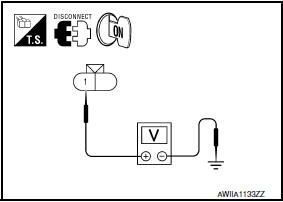

1.CHECK VOLTAGE BETWEEN AMBIENT SENSOR AND GROUND

- Disconnect ambient sensor connector.

- Turn ignition switch ON.

- Check voltage between ambient sensor harness connector E211 terminal 1 and ground.

1 - Ground: Approx. 5V

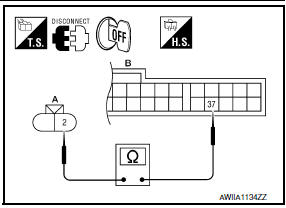

2.CHECK CONTINUITY BETWEEN AMBIENT SENSOR AND A/C AUTO AMP.

- Turn ignition switch OFF.

- Disconnect A/C auto amp. connector.

- Check continuity between ambient sensor harness connector E211 (A) terminal 2 and A/C auto amp. harness connector M37(B) terminal 37.

2 - 37: Continuity should exist.

3.CHECK AMBIENT SENSOR

Check ambient sensor.

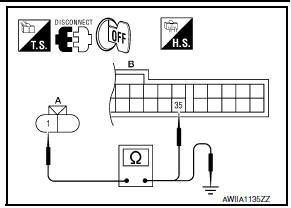

4.CHECK CONTINUITY BETWEEN AMBIENT SENSOR AND A/C AUTO AMP.

- Turn ignition switch OFF.

- Disconnect A/C auto amp. connector.

- Check continuity between ambient sensor harness connector E211 (A) terminal 1 and A/C auto amp. harness connector M37 (B) terminal 35.

1 - 35: Continuity should exist.

- Check continuity between ambient sensor harness connector E211 (A) terminal 1 and ground.

1 - Ground: Continuity should not exist.

Component Inspection

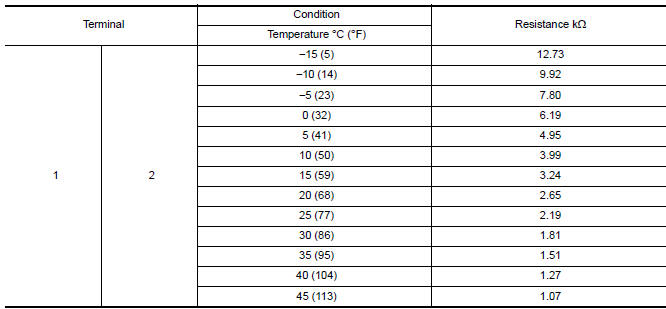

1.CHECK AMBIENT SENSOR

- Turn ignition switch OFF.

- Disconnect ambient sensor connector.

- Check resistance between ambient sensor terminals.

U1010 control unit (CAN)

U1010 control unit (CAN)

Description

Initial diagnosis of A/C auto amp.

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

Using CONSULT, perform "SELF-DIAGNOSIS RESULT ...

B2578, B2579 in-vehicle sensor

B2578, B2579 in-vehicle sensor

Description

In-vehicle Sensor

The in-vehicle sensor (1) is located on instrument lower cover

(LH).

It converts variations in compartment air temperature drawn from

the aspirator into a resi ...

Other materials:

Telescopic switch

Description

ADP steering switch (telescopic switch) is equipped to the steering column.

The operation signal is input to the automatic drive positioner control unit

when the telescopic switch is operated.

Component Function Check

1. CHECK FUNCTION

Select "TELESCO SW-FR", "TELESCO SW-RR" i ...

Audio system

SYSTEM DESCRIPTION

AUDIO SYSTEM

System Diagram

System Description

AUDIO SYSTEM

The audio system consists of the following components

Audio unit

Display unit

Bluetooth control unit

Window antenna

Steering wheel audio control switches

Front door speakers

Tweeters

Rear door s ...

Hazard function

Symptom Table

HAZARD AND BUZZER REMINDER FUNCTION MALFUNCTION

NOTE:

Before performing the diagnosis in the following table, check

"Work flow". Refer to DLK-9, "Work Flow".

If the following symptoms are detected, check systems shown in

the "Diagnosis/service procedure" column ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0052