Nissan Maxima Service and Repair Manual: Trunk lamp switch

Description

Detects trunk open/close condition.

Component Function Check

1. CHECK FUNCTION

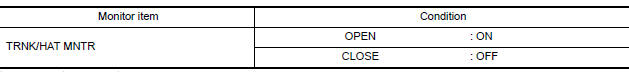

With CONSULT

Check TRNK/HAT MNTR in Data Monitor mode with CONSULT.

Diagnosis Procedure

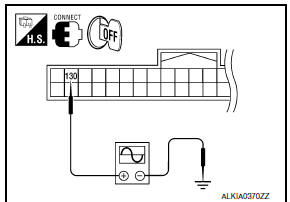

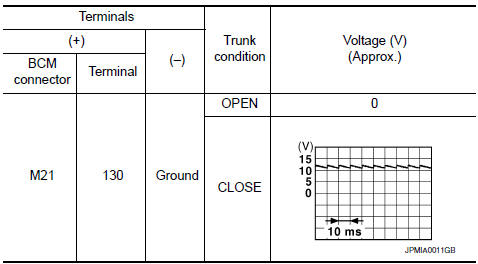

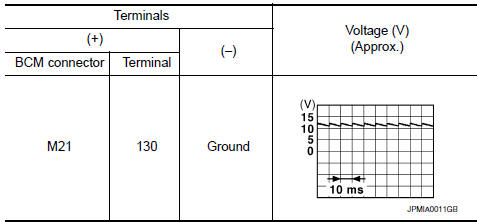

1. CHECK TRUNK LAMP SWITCH INPUT SIGNAL

- Turn ignition switch OFF.

- Check voltage between BCM connector and ground

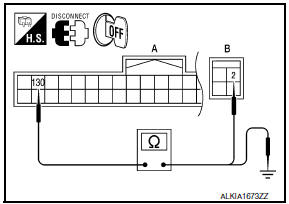

2. CHECK TRUNK LAMP SWITCH CIRCUIT

- Disconnect BCM connector.

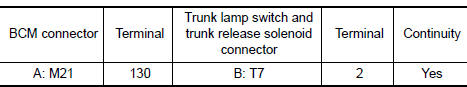

- Check continuity between BCM connector and trunk lamp switch and trunk release solenoid connector.

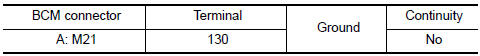

- Check continuity between BCM connector and ground

3. CHECK TRUNK LAMP SWITCH GROUND CIRCUIT

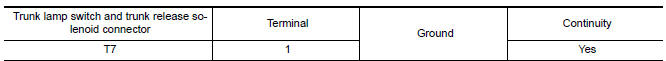

Check continuity between trunk lid lock assembly connector and ground.

4. CHECK BCM OUTPUT SIGNAL

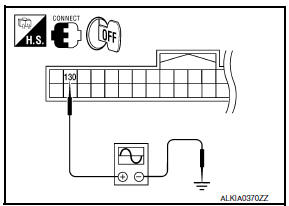

- Insure trunk remains closed during this step.

- Connect BCM connector.

- Check voltage between BCM connector and ground.

5. CHECK TRUNK ROOM LAMP SWITCH

6. CHECK INTERMITTENT INCIDENT

Component Inspection

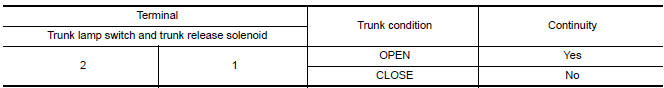

1. CHECK TRUNK LAMP SWITCH

- Turn ignition switch OFF.

- Disconnect trunk lamp switch and trunk release solenoid connector.

- Check trunk lamp switch.

Trunk lid opener cancel switch

Trunk lid opener cancel switch

Description

Cancels trunk lid open operation.

Component Function Check

1. CHECK FUNCTION

With CONSULT

Check trunk lid opener cancel switch TR CANCEL SW in Data Monitor mode with

CONSULT.

...

Door request switch

Door request switch

Description

Transmits door lock/unlock operation to BCM.

Component Function Check

1. CHECK FUNCTION

With CONSULT

Check door request switch REQ SW-DR, REQ SW-AS in Data Monitor mode.

Diagno ...

Other materials:

Main line between ADP and DLC circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (connector side

and harness side).

Harness connector B1

Harness connect ...

Sunshade system does not operate properly

Diagnosis Procedure

1.CHECK SUNSHADE MECHANISM

Check the following.

Operation malfunction caused by sunshade mechanism deformation,

pinched harness or other foreign materials

Operation malfunction and interference with other parts by poor

installation

2.CHECK SUNSHADE MOTOR ASSEMBLY ...

B2636, B2637, B2638, B2639, B2654, B2655 mode door motor

Description

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motor (1) is attached to the heater & cooling unit

assembly.

It rotates so that air is discharged from the outlet set by the

A/C

auto amp. Motor rotation is conveyed to a link which activates the

mode door

DT ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.006