Nissan Maxima Service and Repair Manual: Trunk lid

TRUNK LID ASSEMBLY

TRUNK LID ASSEMBLY : Removal and Installation

CAUTION:

- Use two people when removing or installing trunk lid assembly due to its heavy weight.

- Use protective tape or shop cloths to protect surrounding components from damage during removal and installation of trunk lid assembly.

REMOVAL

- Remove trunk lid finisher. Refer to INT-36, "Removal and Installation".

- Disconnect the harness connectors in the trunk lid, remove the harness clips, and then pull the harness out of the trunk lid.

- Remove the nuts and the trunk lid assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- After installation, check trunk lid open/close, lock/unlock operation.

- After installation, perform the trunk lid assembly adjustment procedure

TRUNK LID ASSEMBLY : Adjustment

- Trunk lid assembly

- Body side outer

- Rear combination lamp

- Rear bumper fascia

Front

Front

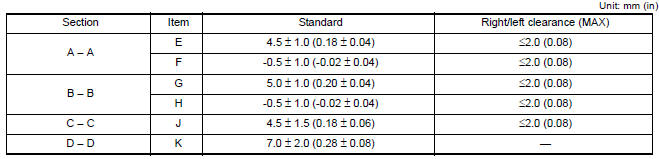

Check the clearance and the surface height between trunk lid and each part by visual inspection and tactile feel

If the clearance and the surface height are out of specification, adjust them according to the adjustment procedures.

LONGITUDINAL CLEARANCE

Trunk Lid Removed From Hinge

- Loosen the trunk lid to hinge bolts.

- Move the trunk lid so that the clearance measurements are within specifications provided.

- Tighten the trunk lid to hinge bolts.

Trunk Lid Hinge Removed From Vehicle

- Remove the parcel shelf trim. Refer to INT-28, "Removal and Installation".

- Loosen the hinge to parcel shelf bolts.

- Move the trunk lid so that the clearance measurements are within specifications provided.

- Tighten the hinge to parcel shelf bolts.

- Install the parcel shelf trim. Refer to INT-28, "Removal and Installation".

SURFACE HEIGHT ADJUSTMENT

- Loosen the bumper rubber.

- Loosen the striker bolts.

- Lift up the trunk lid approx. 100 - 150 mm (3. 94 - 5. 91 in) then close it lightly. Make sure it engages firmly with the trunk lid closed.

- Tighten the trunk lid striker.

TRUNK LID LOCK

TRUNK LID LOCK : Removal and Installation

LOCK

Removal

- Remove the trunk lid finisher. Refer to INT-36, "Removal and Installation".

- Remove the trunk lid lock bolts.

- Disconnect the harness connector and emergency release handle from the trunk lid lock and remove.

Installation

Installation is in the reverse order of removal.

- Remove the trunk rear finisher. Refer to INT-36, "Removal and Installation".

- Remove the bolts and the striker.

Installation

Installation is in the reverse order of removal.

NOTE: Align the trunk lid lock. Refer to DLK-228, "TRUNK LID LOCK : Removal and Installation".

TRUNK LID STAY

TRUNK LID STAY : Disposal

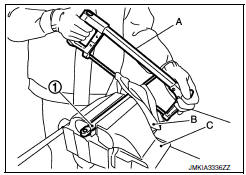

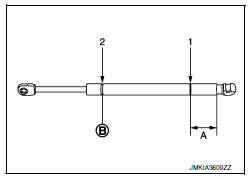

- Fix trunk lid stay (1) using a vise (C).

- Using hacksaw (A) slowly make 2 holes in the trunk lid stay, in numerical order as shown.

CAUTION:

- When cutting a hole on trunk lid stay, always cover hacksaw with a shop cloth (B) to avoid scattering metal fragments or oil.

- Wear eye protection (safety glasses).

- Wear gloves.

A: 20 mm (0. 8 in)

B: Cut at the groove.

Door lock

Door lock

FRONT DOOR LOCK

FRONT DOOR LOCK : Exploded View

Door key cylinder outside handle escutcheon

assembly (drivers side)

Outside handle escutcheon (passenger side)

Rear gasket

Striker

...

Door switch

Door switch

Exploded View

Door switch

Removal and Installation

REMOVAL

Remove the door switch screw (A).

Disconnect the harness connector from the door switch (1) and

remove

INSTALLAT ...

Other materials:

U1310 AV control unit

Description

Part name

Description

AV CONTROL UNIT

It is the master unit of the MULTI AV system and it is connected

to each control unit by means of communication. It operates each

system according to communication signals from the AV contro ...

Locking with power door lock switch

To lock all the doors without a key, push the door

lock switch (driver's or front passenger's side) to

the lock position 1 . When locking the door this

way, be certain not to leave the key inside the

vehicle.

To unlock all the doors without a key, push the

door lock switch (driver's or f ...

Rear door speaker

Removal and Installation

REMOVAL

Remove the rear door finisher. Refer to INT-21, "Removal and

Installation".

Remove the rear door speaker screws (A).

Disconnect the harness connector (B) from the rear door speaker

(1) and remove.

INSTALLATION

Installation is in the reverse order ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0063