Nissan Maxima Service and Repair Manual: Key cylinder switch

Description

The main power window and door lock/unlock switch detects condition of the door key cylinder switch and transmits to BCM as the LOCK or UNLOCK signal.

Component Function Check

1.CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

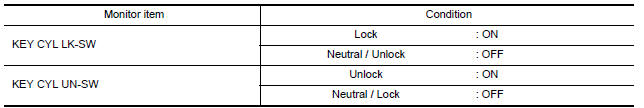

Check KEY CYL UN-SW, KEY CYL UN-SW in "DATA MONITOR" mode for "POWER DOOR LOCK SYSTEM" with CONSULT. Refer to BCS-19, "DOOR LOCK : CONSULT Function (BCM - DOOR LOCK)".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SEC-136, "Wiring Diagram".

1.CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

-

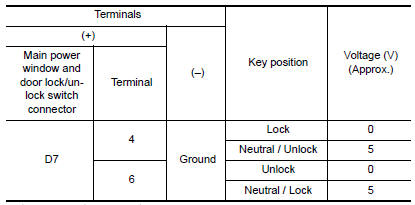

Turn ignition switch ON.

-

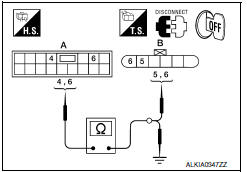

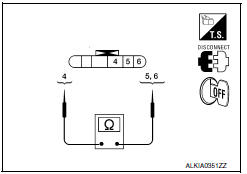

Check voltage between main power window and door lock/ unlock switch harness connector D7 terminal 4, 6 and ground.

2.CHECK DOOR KEY CYLINDER SIGNAL CIRCUIT

-

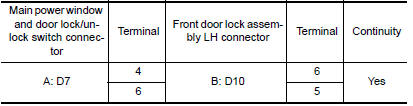

Turn ignition switch OFF.

-

Disconnect main power window and door lock/unlock switch connector and front door lock assembly LH connector.

-

Check continuity between main power window and door lock/ unlock switch harness connector D7 (A) terminal 4, 6 and front door lock assembly LH harness connector D10 (B) 5, 6.

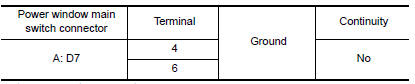

4. Check continuity between main power window and door lock/ unlock switch harness connector D7 (A) 4, 6 and ground.

3.CHECK DOOR KEY CYLINDER SWITCH GROUND CIRCUIT

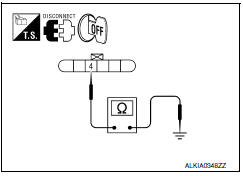

Check continuity between front door lock assembly LH harness connector D10 terminal 4 and ground.

4.CHECK DOOR KEY CYLINDER SWITCH

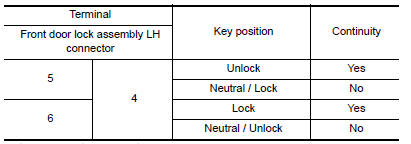

Check door key cylinder switch.

Refer to SEC-86, "Component Inspection".

Component Inspection

COMPONENT INSPECTION

1.CHECK DOOR KEY CYLINDER SWITCH

Check front door lock assembly LH.

Special Repair Requirement

1. PERFORM INITIALIZATION PROCEDURE

Perform initialization procedure. Refer to PWC-7, "ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Special Repair Requirement" and PWC-7, "ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Requirement".

GO TO 2

2. CHECK ANTI-PINCH OPERATION

Check anti-pinch operation. Refer to PWC-7, "ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Special Repair Requirement" and PWC-7, "ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Requirement".

End.

Key slot illumination

Key slot illumination

Description

Blinks when Intelligent Key insertion is required.

Component Function Check

1.CHECK FUNCTION

With CONSULT

Check key slot illumination ("KEY SLOT ILLUMI") Active

Test mode.

Diagnos ...

Horn

Horn

Description

Horn (high/low) is located inside of front bumper and

operates when theft warning system is in alarm phase.

Component Function Check

1.CHECK FUNCTION

Select HORN in "ACTI ...

Other materials:

Sunshade system does not operate properly

Diagnosis Procedure

1.CHECK SUNSHADE MECHANISM

Check the following.

Operation malfunction caused by sunshade mechanism deformation,

pinched harness or other foreign materials

Operation malfunction and interference with other parts by poor

installation

2.CHECK SUNSHADE MOTOR ASSEMBLY ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and

"SEAT BELTPRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT

PRE-TENSIONER", used alongwith a front seat belt, helps to reduce the risk

or severity of injury to the driver and front passenger for c ...

Rear seat

Exploded View - Fixed Seatback

Headrest

Headrest holder (free)

Headrest holder (locked)

Bumper

Seatback assembly

Seatback trim

Seatback pad

Seat cushion trim

Seat cush ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.006