Nissan Maxima Service and Repair Manual: IPDM E/R (intelligent power distribution module engine room)

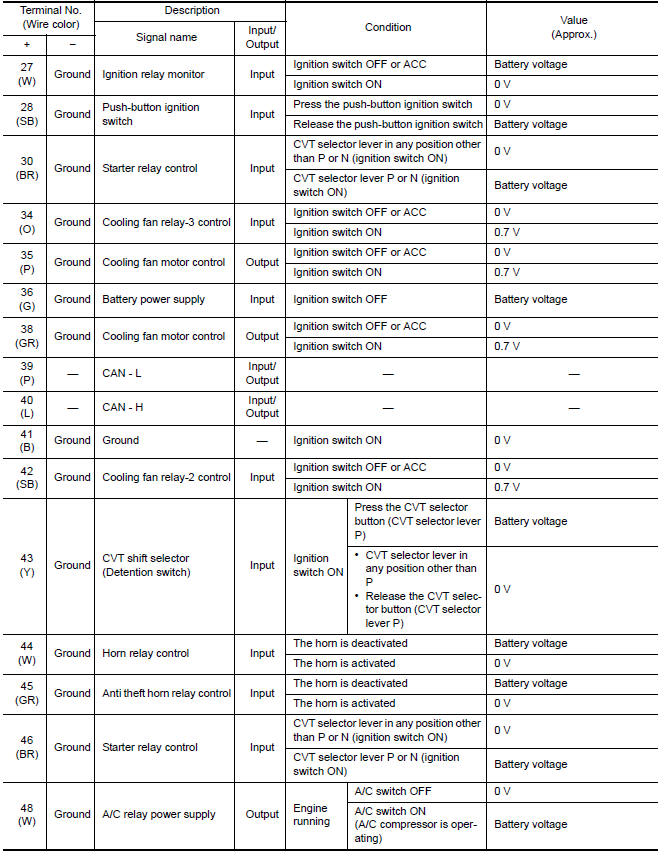

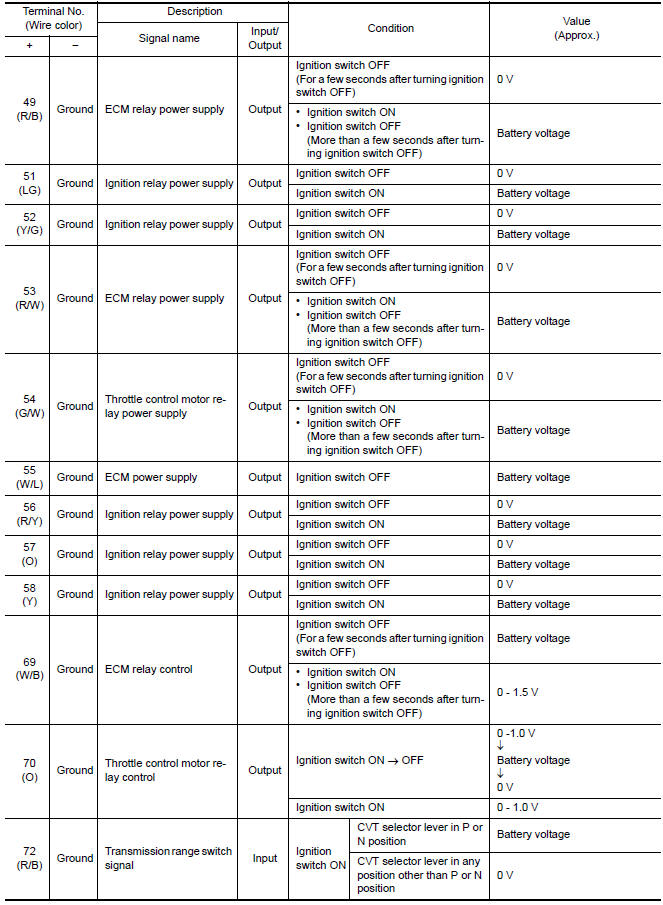

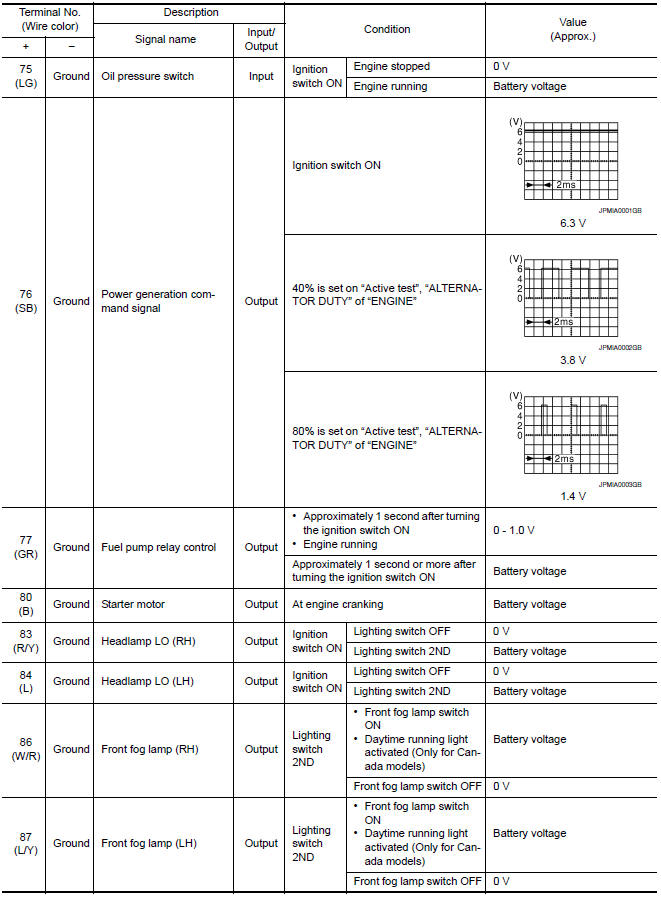

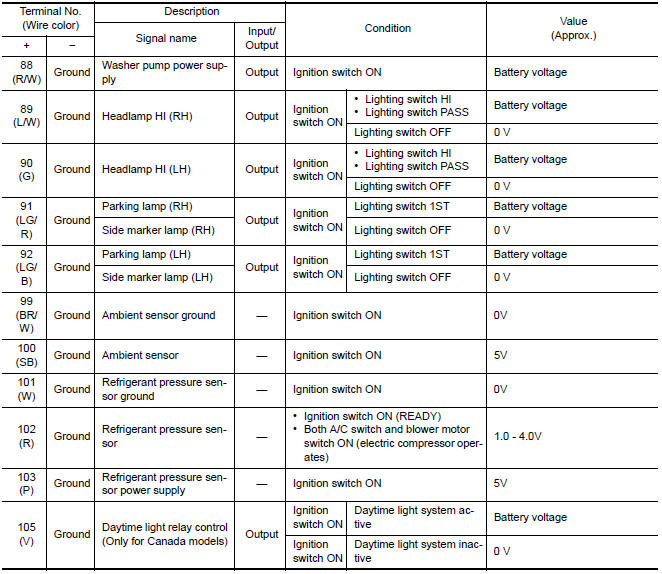

Reference Value

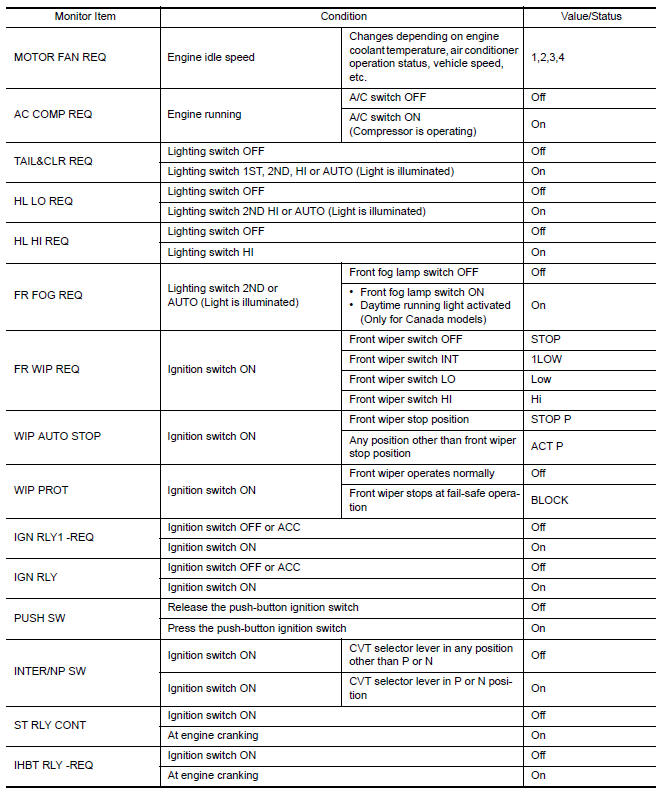

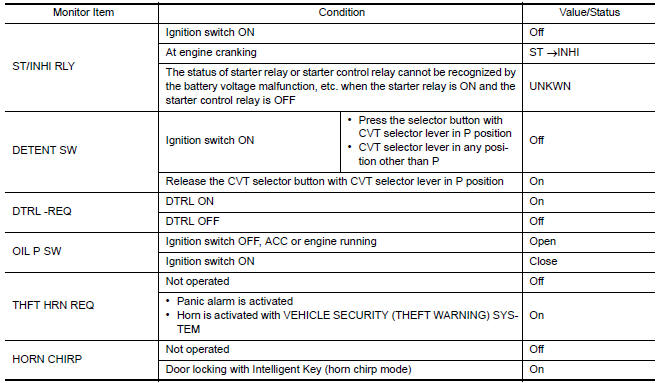

VALUES ON THE DIAGNOSIS TOOL

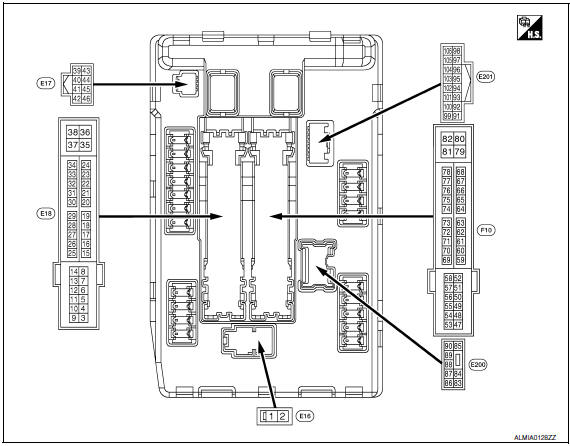

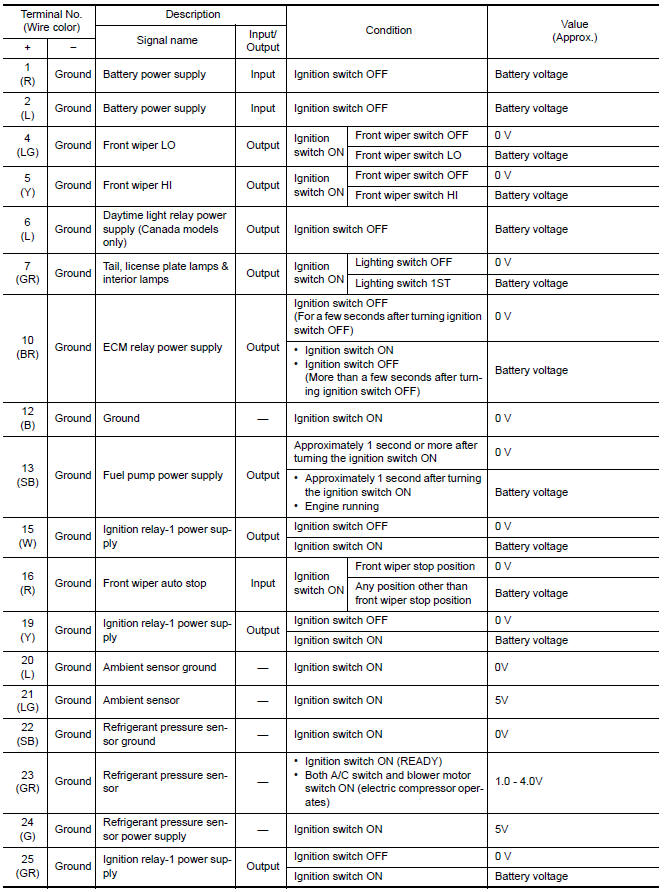

TERMINAL LAYOUT

PHYSICAL VALUES

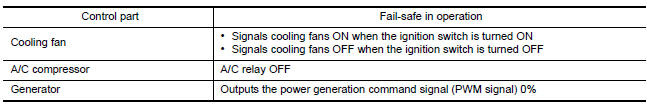

Fail Safe

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

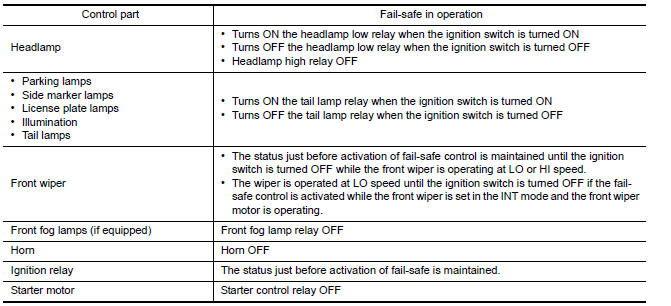

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

-

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay-1 inside it.

-

IPDM E/R judges the ignition relay-1 error if the voltage differs between the contact circuit and the excitation coil circuit.

-

If the ignition relay-1 cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay-1 malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

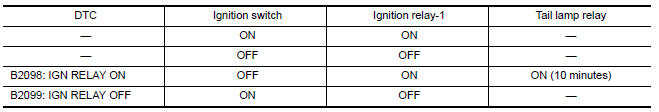

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper after repeating a front wiper 10 seconds activation and 20 seconds stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R "Data Monitor" that displays "BLOCK" for the item "WIP PROT" while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains active for 90 seconds.

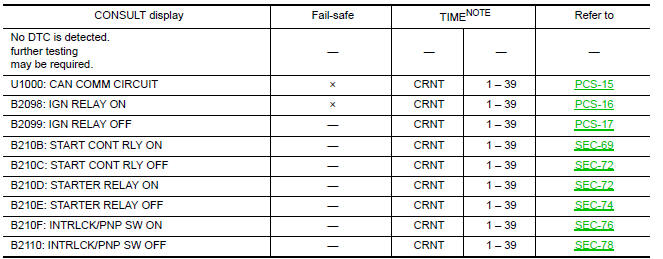

DTC Index

NOTE:

The details of TIME display are as follows.

-

CRNT: The malfunctions that are detected now

-

1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It increases like 0 → 1 → 2 → 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is detected again in the process.

BCM (body control module)

BCM (body control module)

Reference Value

NOTE:

The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and dis ...

Wiring diagram

Wiring diagram

...

Other materials:

Front fog lamp

System Diagram

System Description

BCM (Body Control Module) controls front fog lamp operation.

IPDM E/R (Intelligent Power Distribution Module Engine Room) operates

front fog lamp according to CAN communication signals from BCM.

Combination meter operates front fog lamp indicator accor ...

A-bag branch line circuit

Diagnosis Procedure

WARNING:

Always observe the following items for preventing accidental

activation.

- Before servicing, turn ignition switch OFF, disconnect battery negative

terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

- Never use unspecified tester or other ...

Oil pan

Exploded View

Transaxle assembly

Oil pan bolt

Drain plug

O-ring

Oil pan

Oil pan gasket

Magnet

Apply CVT Fluid NS-2

Removal and Installation

REMOVAL

Drain CVT fluid from CVT. ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0066