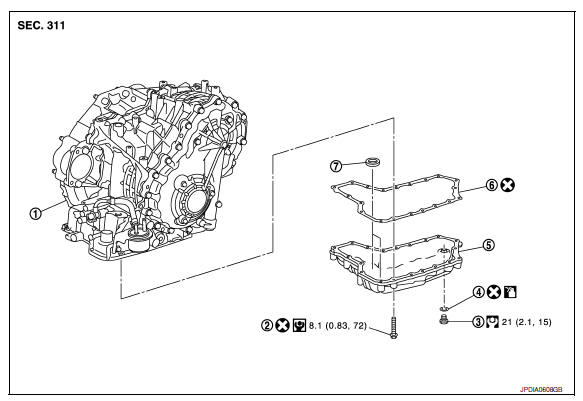

Nissan Maxima Service and Repair Manual: Oil pan

Exploded View

-

Transaxle assembly

-

Oil pan bolt

-

Drain plug

-

O-ring

-

Oil pan

-

Oil pan gasket

-

Magnet

Apply CVT Fluid NS-2

Apply CVT Fluid NS-2

Removal and Installation

REMOVAL

-

Drain CVT fluid from CVT. Refer to TM-156, "Changing".

-

Remove O-ring from drain plug.

-

Remove oil pan bolts (

).

).-

: Front

: Front

-

-

Remove oil pan.

5. Remove oil pan gasket (1) from oil pan (2).

6. Remove magnet (3) from oil pan.

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

-

Completely remove all moisture, oil and old gasket, etc. from the oil pan gasket mating surface of transaxle case and oil pan.

-

Do not reuse oil pan gasket, O-ring and oil pan bolts.

-

Apply CVT fluid to O-ring.

-

Install the oil pan assembly to the transaxle case with the following procedure.

-

Install the oil pan assembly to the transaxle case, and then temporarily tighten the oil pan bolts.

-

CAUTION:

Do not reuse oil pan bolts.

-

Tighten the oil pan bolts in a criss cross pattern to the specified torque.

-

Tighten the oil pan bolts again clockwise to the specified torque.

Inspection

Check foreign materials in oil pan to help determine causes of malfunction. If the CVT fluid is very dark, smells burned, or contains foreign particles, frictional material (clutches) may need replacement. A tacky film that will not wipe clean indicates varnish build up. Varnish can cause valves and clutches to stick and can inhibit pump pressure.

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to TM-155, "Inspection".

Paddle shifter

Paddle shifter

Exploded View

Steering column assembly

Paddle shifter (shift-down)

Paddle shifter (shift-up)

Removal and Installation

REMOVAL

Park the ...

Control valve

Control valve

Exploded View

Transaxle assembly

Control valve

Snap ring

Collar

Manual plate

Lock nut

Lock nut

...

Other materials:

ECM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (unit side and connector

side).

- Models without automatic drive position ...

Front tweeter

Removal and Installation

REMOVAL

Remove the front pillar finisher. Refer to INT-24, "Removal and

Installation".

Remove the front tweeter speaker grille. Refer to IP-10, "Exploded

View".

Remove the front tweeter speaker screws (A).

Pull out front tweeter speaker (1), disconnect the ...

Unlocking doors

1. Press the button on the

Intelligent

Key.

2. The driver's door will unlock and the hazard

warning lights flash once, and the front and

tail lights will turn on for 30 seconds.

3. Press the button again

within one

minute, the outside buzzer sounds once and

the remai ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069