Nissan Maxima Service and Repair Manual: Power generation voltage variable control system

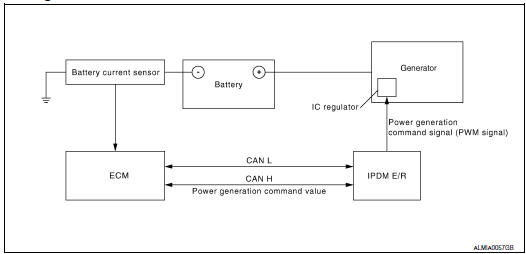

System Diagram

System Description

Power generation variable voltage control system has been adopted. By varying the voltage to the generator, engine load due to power generation of the generator is reduced and fuel consumption is decreased.

NOTE: When any malfunction is detected in the power generation variable voltage control system, power generation is performed according to the characteristic of the IC regulator in the generator.

Component Description

|

Component part |

Description |

| Battery current sensor | The battery current sensor is installed on the battery cable at the negative terminal. The battery current sensor detects the charging/ discharging current of the battery and sends a voltage signal to the ECM according to the current value detected. |

| ECM | The battery current sensor detects the charging/discharging current

of the battery. The ECM judges the battery condition based on

this signal.

The ECM judges whether to request more output via the power generation voltage variable control according to the battery condition. When performing the power generation voltage variable control, the ECM calculates the target power generation voltage according to the battery condition and sends the calculated value as the power generation command value to the IPDM E/R. |

| IPDM E/R | The IPDM E/R converts the received power generation command value into a pulse width modulated (PWM) command signal and sends it to the IC regulator |

| Generator (IC regulator) | The IC regulator controls the power generation voltage by the target

power generation voltage based on the received PWM command

signal.

When there is no PWM command signal, the generator performs the normal power generation according to the characteristic of the IC regulator. |

Charging system

Charging system

System Diagram

System Description

The generator provides DC voltage to operate the vehicle's electrical system

and to keep the battery charged.

The voltage output is controlled by the IC re ...

DTC/circuit diagnosis

DTC/circuit diagnosis

CHARGING SYSTEM PRELIMINARY INSPECTION

Diagnosis Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight

2.CHECK FUSE

Check for blown fuse and fusible link.

...

Other materials:

C1121, C1123, C1125, C1127 out ABS sol

Description

The solenoid valve increases, holds or decreases the fluid pressure of each

brake caliper according to the signals

transmitted by the ABS actuator and electric unit (control unit).

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Check ...

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the

condition and the environment when the incident/malfunction occurred).

2. CHECK DTC

Check DTC.

Perform the following procedure if DTC is displa ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT PRE-TENSIONER",

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0059