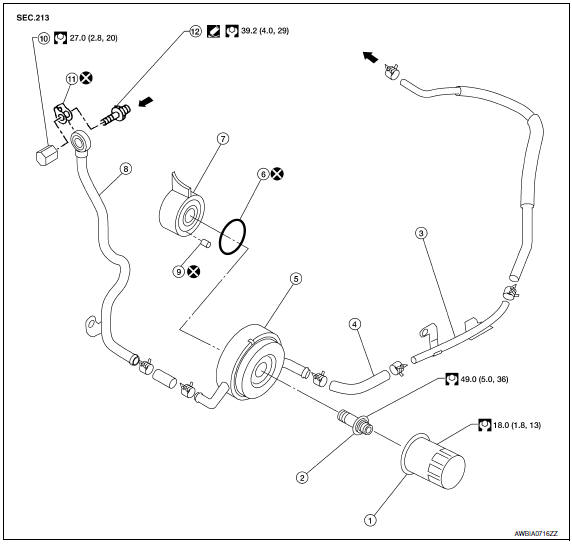

Nissan Maxima Service and Repair Manual: Oil cooler

Removal and Installation

- Oil filter

- Oil cooler bolt

- Water pipe

- Water hose

- Oil cooler

- O-ring

- Oil pan

- Water pipe

- Relief valve

- Water drain plug

- Copper gasket

- Water connector

Engine coolant flow

Engine coolant flow

WARNING: Be careful not to get burned, engine coolant and engine oil may be hot.

CAUTION:

- When removing oil cooler, prepare a shop cloth to absorb any engine oil leakage or spillage.

- Completely wipe off any engine oil that adheres to the engine and the vehicle.

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove the engine under cover. Refer to EXT-15, "Exploded View".

- Remove the RH wheel and tire. Refer to WT-60, "Adjustment".

- Remove the front fender protector side cover (RH). Refer to EXT-23, "Exploded View".

- Drain engine coolant. CAUTION: Do not spill coolant on the drive belt.

- Disconnect water hoses from oil cooler.

- Remove the oil filter. Refer to LU-10, "Removal and Installation".

- Remove oil cooler.

INSPECTION AFTER REMOVAL

- Check oil cooler for cracks.

- Check oil cooler for clogging by blowing through coolant inlet. If necessary, replace oil cooler.

Oil Pressure Relief Valve

Inspect oil pressure relief valve for movement, cracks and breaks by pushing the ball. If replacement is necessary, remove valve by prying it out with a suitable tool. Install a new valve in place by tapping it.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-ring.

- Do not reuse copper gasket.

- When installing the oil cooler, align the oil cooler stopper with the stopper of the oil pan.

- Replace oil pressure relief valve after every removal.

INSPECTION AFTER INSTALLATION

Start engine and check for engine oil and coolant leaks. Repair as necessary.

Oil pump

Oil pump

Removal and Installation

REMOVAL

Remove the engine from the vehicle. Refer to EM-103, "Removal and

Installation".

Remove the upper oil pan. Refer to EM-37, "Removal and

Instal ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Oil Pressure

Regulator Valve

Oil Pump

Oil Capacity

...

Other materials:

ABS branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ABS actuator and

electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

...

RCTA system operation

1. Side BSW/RCTA Indicator Light

2. BSW/RCTA Indicator

The RCTA system can help alert the driver of an

approaching vehicle when the driver is backing

out of a parking space.

When the shift position is in R (Reverse) and the

vehicle speed is less than approximately 5 mph

(8 km/h), the RC ...

Diagnosis system (audio unit)

Diagnosis Description

Self-diagnosis mode can perform the following items.

Versions display

Channel check diagnosis

Key check diagnosis

AV communication diagnosis

VERSIONS DISPLAY FUNCTION

Turn ignition switch ON.

Turn the audio unit off.

While pressing "1" button, turn volume ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.006