Nissan Maxima Service and Repair Manual: P0014, P0024 EVT control

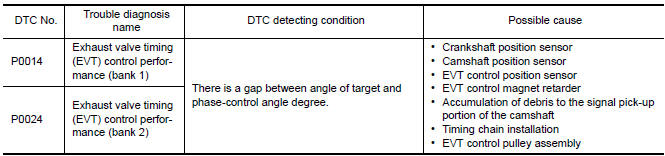

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC P0014 or P0024 is displayed with DTC P0078, P0084 first perform trouble diagnosis for DTC P0078, P0084. Refer to EC-180, "DTC Logic".

- If DTC P0014 or P0024 is displayed with DTC P1078, P1084 first perform trouble diagnosis for DTC P1078, P1084

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is between 10 V and 16 V at idle.

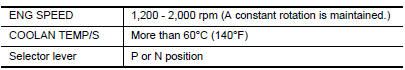

2.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

- Turn ignition switch ON and select "DATA MONITOR" mode with CONSULT.

- Start engine and warm it up to the normal operating temperature.

- Maintain the following conditions for at least 6 consecutive seconds.Hold the accelerator pedal as steady as possible.

- Let engine idle for 10 seconds.

- Check 1st trip DTC.

With GST

Follow the procedure "With CONSULT" above.

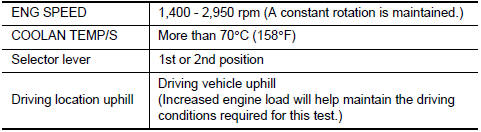

3.PERFORM DTC CONFIRMATION PROCEDURE-II

With CONSULT

- Select "DATA MONITOR" mode with CONSULT.

- Maintain the following conditions for at least 20 consecutive seconds.

CAUTION: Always drive vehicle at a safe speed.

- Check 1st trip DTC.

With GST

Follow the procedure "With CONSULT" above.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to EC-554, "Wiring Diagram".

1.CHECK FUNCTION OF EXHAUST VALVE TIMING (EVT) CONTROL

With CONSULT

- Turn ignition switch ON.

- Select "EXH V/T ASSIGN ANGLE" in "ACTIVE TEST" mode with CONSULT.

- Start engine and keep the engine speed at 2,500 rpm, then touch "START".

- Check that the values of "EXH/V TIM B1" and "EXH/V TIM B2" change when touching "UP" or "DOWN".

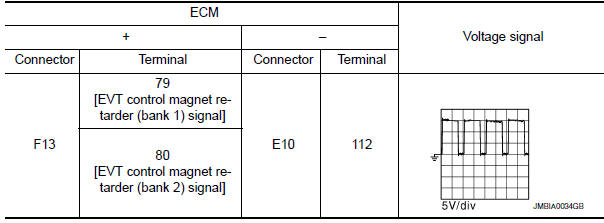

Without CONSULT

- Start engine and rev engine up above 1,500 rpm.

- Read the voltage signal between ECM harness connector terminals as per the following with an oscilloscope.

2.CHECK EVT CONTROL MAGNET RETARDER

3.REPLACE EVT CONTROL MAGNET RETARDER

- Replace malfunctioning EVT control magnet retarder.

4.CHECK EVT CONTROL POSITION SENSOR

5.CHECK CRANKSHAFT POSITION SENSOR

6.CHECK CAMSHAFT POSITION SENSOR

7.CHECK CAMSHAFT (EXH)

Check the following.

- Accumulation of debris to the signal plate of camshaft rear end

- Chipping signal plate of camshaft rear end

8.CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment.

9.REPLACE EVT CONTROL PULLEY ASSEMBLY

- Replace camshaft sprocket (EXH) and EVT control magnet retarder.

10.CHECK INTERMITTENT INCIDENT

Component Inspection

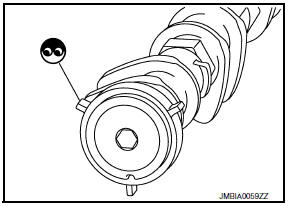

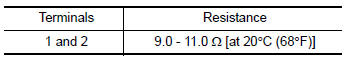

1.CHECK EXHAUST VALVE TIMING CONTROL MAGNET RETARDER

- Turn ignition switch OFF.

- Disconnect exhaust valve timing control magnet retarder harness connector

- Check resistance between exhaust valve timing control magnet retarder terminals as per the following.

2.REPLACE EXHAUST VALVE TIMING CONTROL MAGNET RETARDER

- Replace malfunctioning exhaust valve timing control magnet retarder

P0011, P0021 IVT control

P0011, P0021 IVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0011 or P0021 is displayed with DTC P0075, P0081, first perform the

trouble diagnosis for DTC

P0075, P0081.

DTC CONFIRMATION PROCEDURE

1.PRECO ...

P0031, P0032, P0051, P0052 A/F sensor 1 heater

P0031, P0032, P0051, P0052 A/F sensor 1 heater

Description

SYSTEM DESCRIPTION

The ECM performs ON/OFF duty control of the A/F sensor 1 heater corresponding

to the engine operating

condition to keep the temperature of A/F sensor 1 element ...

Other materials:

Rear door speaker

Removal and Installation

REMOVAL

Remove the rear door finisher. Refer to INT-21, "Removal and

Installation".

Remove the rear door speaker screws (A).

Disconnect the harness connector (B) from the rear door

speaker (1) and remove.

INSTALLATION

Installation is in the r ...

Subwoofer

Description

The AV control unit sends audio signals to the BOSE speaker amp. The BOSE

speaker amp. amplifies the

audio signals before sending them to the subwoofers using the audio signal

circuits.

Diagnosis Procedure

1.CONNECTOR CHECK

Check the AV control unit, BOSE speaker amp. and subwo ...

U1255 satellite radio tuner

Description

DTC Logic

Diagnosis Procedure

1.CHECK SATELLITE RADIO TUNER POWER SUPPLY AND GROUND CIRCUIT

Check satellite radio tuner power supply and ground circuit.

2.CHECK CONTINUITY COMMUNICATION CIRCUIT AND REQUEST SIGNAL CIRCUIT

Turn ignition switch OFF.

Disconnect AV cont ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0063