Nissan Maxima Service and Repair Manual: P0075, P0081 IVT control solenoid valve

Description

Intake valve timing control solenoid valve is activated by ON/OFF pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil amount and direction of flow via the intake valve timing control unit or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve stops oil pressure flow to fix the intake valve angle at the control position.

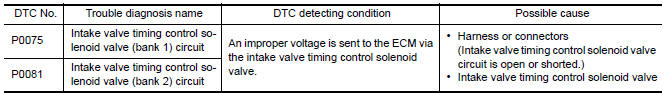

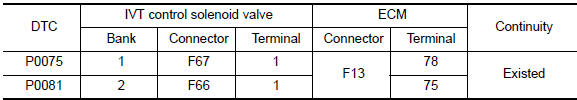

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for 5 seconds.

- Check 1st trip DTC.

Diagnosis Procedure

Regarding Wiring Diagram information

1.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT\

- Turn ignition switch OFF.

- Disconnect intake valve timing control solenoid valve harness connector.

- Turn ignition switch ON.

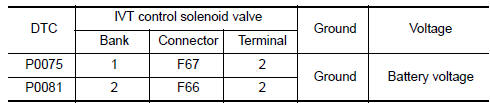

- Check the voltage between intake valve timing (IVT) control solenoid valve harness connector and ground with CONSULT or tester.

2.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between intake valve timing control solenoid valve harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

3.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

4.CHECK INTERMITTENT INCIDENT

Component Inspection

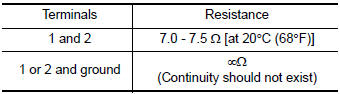

1.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-I

- Disconnect intake valve timing control solenoid valve harness connector.

- Check resistance between intake valve timing control solenoid valve terminals as per the following.

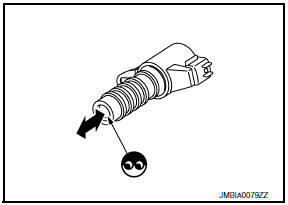

2.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-II

- Remove intake valve timing control solenoid valve. Refer to EM-54, "Exploded View".

- Provide 12 V DC between intake valve timing control solenoid valve terminals 1 and 2, and then interrupt it. Check that the plunger moves as shown in the figure.

CAUTION: Never apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve timing control solenoid valve.

NOTE: Always replace O-ring when intake valve timing control solenoid valve is removed.

P0037, P0038, P0057, P0058 HO2S2 heater

P0037, P0038, P0057, P0058 HO2S2 heater

Description

SYSTEM DESCRIPTION

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater

corresponding to the engine speed,

amount of intake air and engine coolant temperature.

O ...

P0078, P0084 EVT control magnet retarder

P0078, P0084 EVT control magnet retarder

Description

Exhaust valve timing control magnet retarder (1) controls the shut/

open timing of the exhaust valve by ON/OFF pulse duty signals sent

from the ECM.

The longer pulse width reta ...

Other materials:

Display unit

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

...

Door key cylinder switch

Description

The main power window and door lock/unlock switch detects condition of the

door key cylinder switch and

transmits to BCM as the LOCK or UNLOCK signal.

Component Function Check

1.CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

Check KEY CYL UN-SW, KEY CYL UN-SW in "DATA MONITOR" mode ...

Center speaker

Description

The audio unit sends audio signals to the BOSE speaker amp. The BOSE speaker

amp. amplifies the audio signals before sending them to the center speaker

using the audio signal circuits.

Diagnosis Procedure

1.CONNECTOR CHECK

Check the audio unit, BOSE speaker amp. and speaker conne ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0055